Much like the pursuit of high quality is a shared company endeavour and not assigned to one Department, the emphasis on excellent service and support is also a collective goal throughout Belzona’s organisation. The final post in the ‘Differentiating Belzona’ series, examines the importance placed upon adding value to the solutions we provide; particularly, the systems in place allowing Belzona to achieve this on a global scale. The post observes what happens once our materials have been delivered to customers and the support which differentiates Belzona from its competitors.

Tried and tested

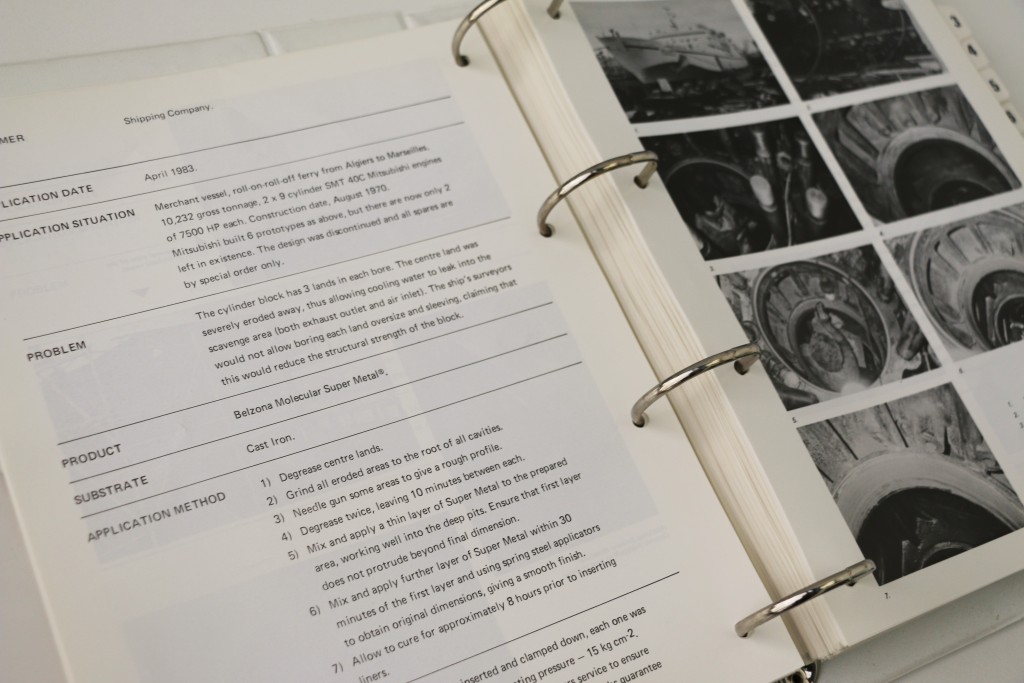

Once Belzona’s materials have been manufactured and passed the quality control procedures, it is not a simple case of releasing them with the best of intentions. Crucially, all materials and newly introduced ones in particular, are closely monitored in terms of their in-field performance. Once several applications have been completed, sufficient feedback is gathered, enabling Belzona to create a product review, which serves as an indication of performance and take-up within the field. This application information is then fed back throughout the company, most importantly into the KHIA database. Levente Bazsanyi, Belzona’s Engineering Services Manager, explains “Belzona create simple, yet detailed case studies, called ‘Know-How in Actions’ (KHIAs) from recorded applications. These case studies are an important tool for both our sales team and clients alike, showing examples of previous or similar applications, including specific details, such as industry, equipment, and operating conditions.

“Dating way back to the 1970s, our KHIA library currently totals over 5000 individual digital case studies, shared across a variety of languages. The sheer amount of application examples emphasises the in-field success of our materials and acts as a seal of approval for their performance. Following reviews and inspection after several years in service these KHIAs can be classified as Elite, highlighting that the repair composite or coating is still performing as anticipated.”

Guidance in the field

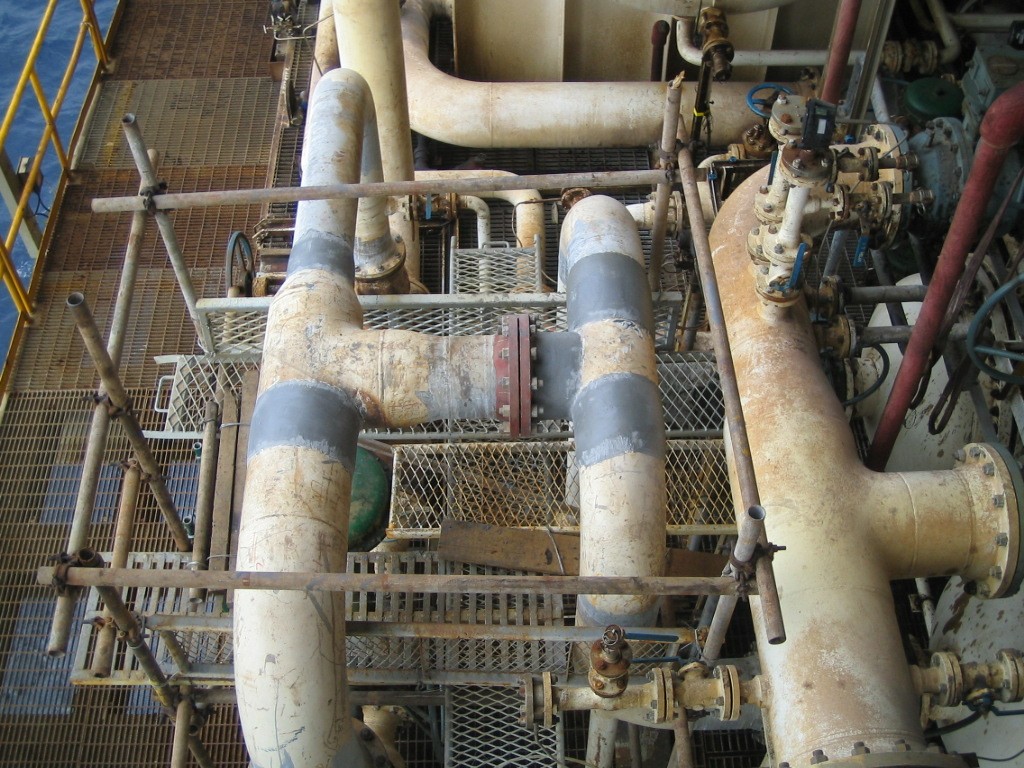

Over 60 years’ worth of experience has clearly shown that no two applications are completely alike. Whether this is due to varying chemical concentrations, or simply different weather or operating conditions, each application needs to be tailored dependent on specific circumstances and requirements. Therefore, support and guidance is integral to the correct material specification and successful application; this is where Belzona’s Engineers come into play. Levente Bazsanyi commented “Of course, every scenario and job is different, so all of our materials need to be carefully selected in relation to these conditions with the help of Product Specification Sheets (PSS), Instructions for Use (IFU), Chemical Resistant Charts (CRC), as well as over 150 System Leaflets which detail general application procedures. Alongside provision of in-depth supporting documentation, our Engineers are globally available 24/7 to offer advice on product selection and application. Customers and Distributors find the additional technical support and assessment of material suitability highly beneficial. In some instances, people are potentially losing millions due to the closure or downtime of equipment and site; therefore, careful selection and responsive support in the field, is crucial for maximising uptime and application success.”

In many instances, Belzona’s field support extends to large-scale engineering projects or designed solutions. Levente continues by saying “As an Engineering Department, we focus on engineering projects in terms of devising comprehensive designs and tailored solutions. Overall, this includes the provision of application procedures and data, validating the solution for the client. For example, SuperWrap II is a compliant composite repair system designed for safety related equipment and Belzona creates engineered calculations to design individual repairs with a built-in lifetime.

“Overall, it is the provision of calculations, data and designs which help to create supporting data and method statements for many of Belzona’s client specifications. In fact, we have established specifications for approved products with key companies in major industries.”

Practice makes perfect

Without sufficient applicator training, all the support and guidance available is not enough to ensure correct procedures and applications are being carried out. In fact, it is within Belzona’s interest that all materials are applied in line with application specifications. Therefore, Belzona provide training for applicators out in the field, to guarantee that they are following the designated protocols assigned to all materials. However, it is not simply the provision of training that differentiates Belzona, but the extent to which training is offered globally.

Levente Bazsanyi said “What differentiates Belzona in terms of training is the varying levels that we provide worldwide and the standardisation of our courses. Fundamentally, we provide two types of core training: Awareness and Validated. As the names suggest, these core training courses range from promoting basic awareness of the product and application, to much more thorough, in-depth certified training which covers both theoretical and practical application skills. With the wide range of Belzona materials available and the vast number of industries that we serve, the ability to tailor our training services to a specific application shows the flexibility of support we can provide.

“Regardless of location, whether the trainee is in our Harrogate head office, regional offices or even on site, the training is standardised so a consistent and correct message is delivered in every session. This reinforces the recommended application standard worldwide and promotes a certain degree of trust in each application carried out under the Belzona name.”

Local support on a global scale

As highlighted, all these elements of service and support are woven into Belzona’s offering to add value to the existing solution. But, without access to that solution worldwide, there would be considerable difficulties faced by customers. Levente Bazsanyi adds, “Clients are often requiring repairs to be carried out in a limited timeframe, which is important when downtime can be a major cost. Local availability is crucial to making sure our global applications are carried out effectively, hence why Belzona operates across over 140 Distributors in 120 different countries. We penetrate globally, making sure that our products are available in every single corner of the world. This means if a customer needs a product, it is available straight away.

“However, our Distributors are not just stockists, as they also share in Belzona’s goal to provide added value. Combining local availability with a professional service, our Distributors provide additional technical and sales support on a local scale, to offer a full client package. Overall, what differentiates Belzona is its extensive knowledge and know-how, demonstrated through proven experience and qualified solutions and most importantly, our ability to consistently show this on a global scale.”

I know about SuperWrap II but I don’t know about relation between pressure and the number of SuperWrap II layers.

Do I need one, two or three layers? How do I calculate this?