BELZONA DISTRIBUTOR IN THE PHILIPPINES CARRIES OUT FRANCIS TURBINE REPAIR PROJECT

Wise Industrial Systems, Inc., (Wise), the exclusive Belzona distributor in the Philippines for over 30 years, recently completed a major turbine repair project for a Hydroelectric Plant located in the Nueva Ecija province Central Luzon. Two Francis turbines housed within the plant were suffering from corrosion, erosion and cavitation in several key areas.

In 2019 the plant operator employed engineers from Wise to perform a series of tests according to their requirements and guidelines on the affected areas of the turbines to ascertain the effectiveness of Belzona products for this type of project.

The Francis Turbine, designed around 1848 by British-American engineer James Bichens Francis is a type of hydro turbine. Water enters the turbine in a radial direction, flowing towards its axis, but after striking and interacting with the turbine blades, it exits along the direction of that axis; for this reason, the Francis turbine is sometimes referred to as a mixed-flow turbine. Due to their high-efficiency rate, Francis turbines are the most widely used hydro turbine contributing approximately 60% of the global hydropower capacity.

The tests found that Belzona solutions offered greater benefits than similar competitive systems, with all the test areas remaining intact and with no significant deterioration observed. Satisfied with the findings, the plant operator agreed to a Belzona turbine repair and protection system of Belzona 1161, 1212, 1321 and 1331 to be applied in different combinations on the affected Stay Vanes, Guide Vanes, Spiral Casing, Draft Tube Cone, Draft Tube Wall and Turbine Runner.

Due to the delicate nature of the instrumentation and other components within the plant, surface preparation by conventional blasting was not permitted due to the risk of contamination. With this in mind, each application surface was prepared manually to remove loose debris, paint, oxides and other contaminants; power tools were then used to achieve a surface standard of SSPC-SP11 bare metal.

The 150 MW Hydroelectric plant started commercial operations on April 5th, 2002 and is part of a multi-purpose project combining irrigation and hydroelectric power by the National Irrigation Administration of the Philippines. The underground powerhouse cavern accommodates two Francis turbines that can produce up to 75 MW; the plant has an estimated energy generation of 730 GWh/year.

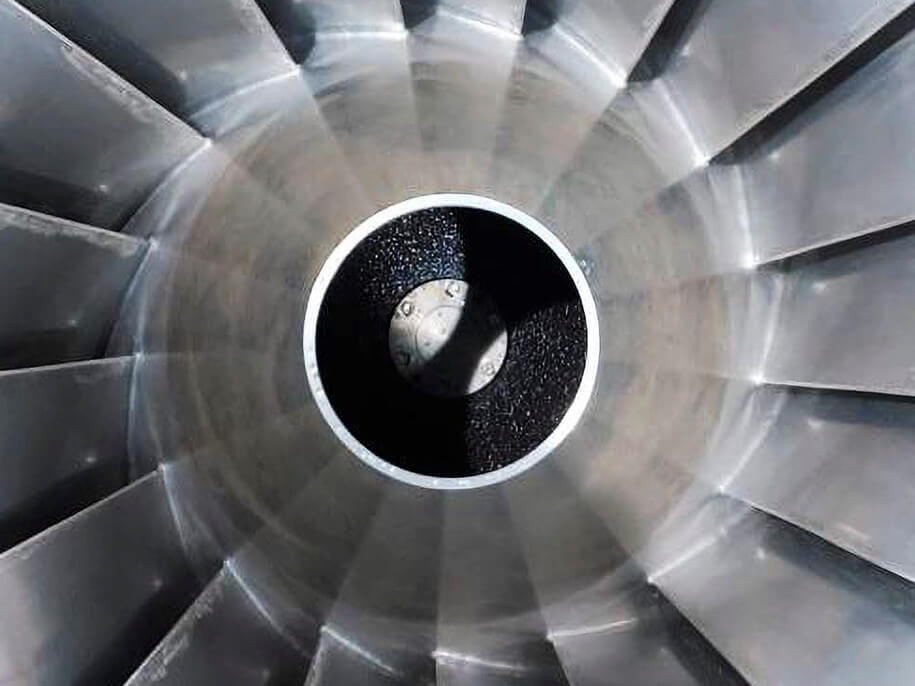

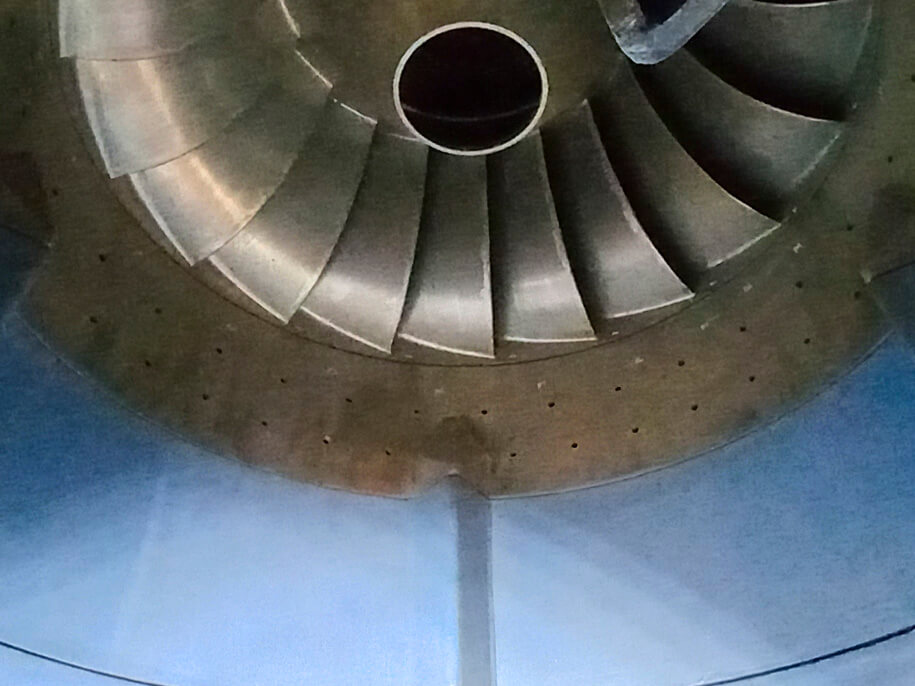

The turbine repair project began with the Stay Vanes and Guide Vanes sections. First, a layer of Belzona 1212 was applied to the surface, followed by two coats of Belzona 1321 (Ceramic S-Metal). Finally, the edges of each vane received a third coat of 1321 for additional protection. The Turbine Runner, which had suffered erosion damage at the root of its vanes, was also repaired using Belzona 1212.

Belzona 1161 and Belzona 1212 are both surface tolerant materials that provide excellent adhesive strength to manually prepared, wet or oil contaminated surfaces, including underwater. Belzona 1321 (Ceramic S-Metal) is a two-component high-strength material that offers outstanding erosion and corrosion resistance under immersed conditions. In addition, the material is resistant to a variety of chemicals, including hydrocarbons and process chemicals.

The Spiral Casing section of the turbine was repaired using a combination of Belzona 1161 and Belzona 1331. Due to the size of the surface area involved, six application specialists from Wise worked simultaneously to complete this section within the given time frame.

Belzona 1331 is a two-component fluid grade system for protecting immersed surfaces of machinery and equipment suffering from erosion and corrosion. It is capable of high-build spray applications in a single coat without sagging.

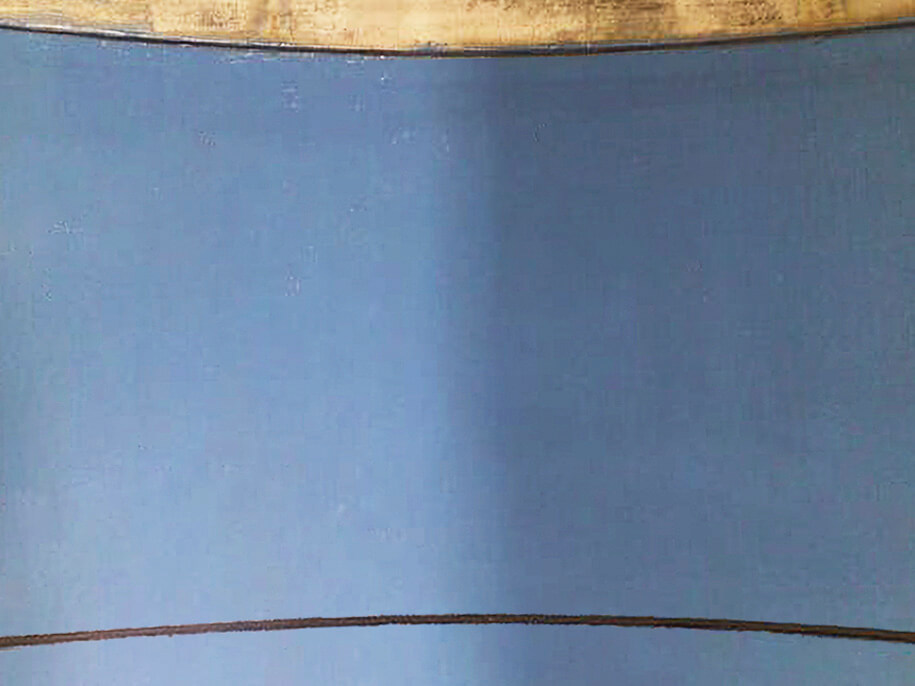

The turbine repair project concluded with the Draft Tube Cone/Wall sections. First, the Draft Tube Cone was coated with Belzona 1212, followed by two coats of Belzona 1321. Next, The Draft Tube Wall was repaired using Belzona 1161 for rebuilding and resurfacing, followed by a single coat of Belzona 1321; both products were applied to the top half of the wall at a depth of 3 meters from the Draft Tube Cone base. Finally, two coats of Belzona 1161 were applied to protect the bottom half of the draft tube wall down to the water level.

Headquartered in Manila, Wise has provided Belzona repair and protection solutions throughout the Philippines and beyond for over 30 years and has firmly established itself as the leading authority on Belzona products, surface preparation tools, equipment and application procedures. Due to their extensive industry knowledge, Wise are able to offer their services to a multitude of sectors, including but not limited to Agricultural, Construction, Marine, Mining, Oil and Gas, Petrochemicals, Power Generation and Renewables.

Click the buttons below to view case studies on other Belzona turbine repair projects: