What is Belzona 5831 (ST-Barrier)?

Belzona 5831 (ST-Barrier) is a two-part surface tolerant epoxy coating specifically formulated for application on wet and oil-contaminated surfaces, as well as for underwater applications. When applied, the product displaces water and contaminants from the surface ensuring maximum adhesion to wet substrates.

Once cured, it forms a robust underwater coating that offers long-term protection against corrosion and deterioration in a wide range of industrial applications, for example:

- Splash zones

- Sweating pipework

- Joints and flanges

- Tanks and bunds

- Submersible equipment

What is Different About Belzona 5831LT?

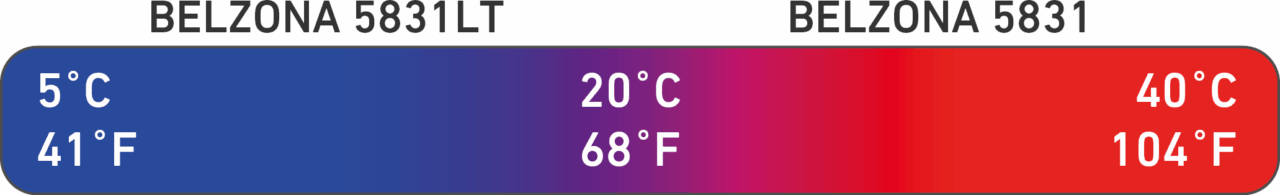

Specifically engineered for application directly onto substrates ranging from 41 °F to 86 °F (5 – 30 °C), with service temperatures down to –40 °F (-40 °C), this surface-tolerant epoxy coating stands as a tailored solution for lower temperatures and colder waters. However, this variant still inherits all the benefits of Belzona 5831 (ST-Barrier), which can be applied on substrates up to 104 °F ( 40 °C), such as moisture tolerance and the ability to displace surface contaminants.

Substrate Temperature:

Both formulations are suitable epoxy for wet conditions and offer long-term protection against corrosion, erosion, and environmental attack for metallic and non-metallic surfaces. A precise selection between the two products can, therefore, be made based on the thermal demands of the application.

Benefits of Belzona 5831 Products:

- Durable, corrosion-resistant barrier coating

- Cures underwater and bonds to wet surfaces

- Tolerant to oil contamination

- No shrinkage, expansion or distortion

- Prevents galvanic corrosion

- No hot work

- Solvent-free, reducing health and safety risks

- Excellent bonding to many metal surfaces including steel, stainless steel and other specialist steels as well as to non-metallic surfaces such as concrete and brick

Step-by-Step: How to Repair and Protect Offshore Risers with Underwater Epoxy

Off the coast of Croatia, an offshore gas platform faced severe riser corrosion after a previous coating failed. The Client needed a surface tolerant solution to repair the damage and prevent future degradation.

Belzona 5831 (ST-Barrier) was selected for its long-term corrosion protection and strong adhesion to wet, minimally prepared surfaces, ideal for harsh marine conditions. It’s easy, in-situ application also made it a practical choice. Given the warm July weather in the Adriatic Sea, the standard temperature version of the product was chosen. For lower temperature applications, Belzona 5831LT should be used.

The Application:

Step 1: Clean and Prepare the Surface

The surface tolerant nature of Belzona 5831 (ST-Barrier) meant minimal surface preparation was possible, ideal for offshore environments. The affected areas were manually prepared and cleaned to remove loose corrosion and contamination.

Step 2: Mixing Belzona 5831 (ST-Barrier) Surface Tolerant Coating

Belzona 5831 (ST-Barrier) was mixed at a ratio of 1:1 parts base to solidifier by volume, as recommended on the Instructions For Use sheet.

Step 3: Apply the First Coat of Epoxy for Wet Surface Conditions

The product was applied directly onto the manually prepared, damp surfaces using a roller. This ensured full wetting of the substrate and effective corrosion protection, even in less-than-ideal surface conditions.

Step 4: Allow the First Coat to Cure and Apply the Second Coat

Within the overcoat window, apply a second layer of Belzona 5831 (ST-Barrier) to complete the system and provide long-term protection.

The application of Belzona 5831 (ST-Barrier) not only successfully repaired and protected the riser from corrosion but also exemplified this surface tolerant epoxy’s efficacy in safeguarding critical offshore infrastructure.

Hull Repair and Protection with Belzona 5831 (ST-Barrier)

Belzona 5831 (ST-Barrier) is a robust underwater metal protection system, acting as a barrier coating commonly used for hull repair and protection. It bonds effectively to wet or submerged surfaces, making it ideal for hull epoxy coating, as well as for industrial equipment and marine structures that cannot be taken out of service. This allows for corrosion protection without the need for drydock conditions.

Belzona 5831 (ST-Barrier) can also serve as an effective underwater epoxy repair material when applied by trained divers or with minimal water displacement techniques.

Watch Belzona 5831 (ST-Barrier) Applied Underwater

Want to see how Belzona 5831 (ST-Barrier) performs when applied directly underwater? Watch the underwater application video here:

FAQs

1. Can Belzona 5831 (ST-Barrier) be applied underwater or to wet surfaces?

Yes, Belzona 5831 (ST-Barrier) is an underwater epoxy, specifically designed for application to damp, or fully wet surfaces, making it suitable for marine and offshore environments as well as for submersible equipment.

2. Do I need to abrasive blast before applying Belzona 5831 (ST-Barrier)?

No, while surface preparation is highly important, Belzona 5831 (ST-Barrier) is a surface-tolerant epoxy, meaning it can adhere effectively to manually prepared substrates where abrasive blasting isn’t possible.

3. What makes Belzona 5831 (ST-Barrier) different from standard epoxy coatings?

Unlike many conventional epoxies, Belzona 5831 (ST-Barrier) is surface tolerant, offers strong adhesion to wet substrates and provides long-term corrosion resistance, even in immersed or splash zone conditions.

4. Can Belzona 5831 (ST-Barrier) be used for pipe repair?

Yes, it is often used as an epoxy for pipe repair, offering internal and external pipe protection from corrosion, especially in cases where surface dryness cannot be guaranteed.

Learn More

Surface-Tolerant Epoxy: How to Repair Wet and Oily Metal

Contact Your Local Distributor to Learn More About Surface Tolerant Solutions

Based in the Company’s Headquarters in Harrogate, Angus Jackson joined Belzona Ltd in 2024 as a Chemical Engineer. Specialising in repair composites and protective coatings, Angus works closely with Belzona’s authorised Distributor Network, providing technical support and training.

He plays a key role in helping select and apply advanced polymeric materials for asset protection, ensuring long-term performance and reliability. In addition to delivering product training, Angus is actively involved in troubleshooting and optimising solutions for corrosion, erosion, and mechanical damage in industrial systems.

Holding an MEng in Chemical Engineering from Newcastle University, Angus has a background in pipeline engineering and simulation, with expertise in hydraulic analysis for Oil & Gas, water, and wastewater systems. His experience in flow dynamics and system optimisation provides a strong technical foundation for his current work in materials engineering. Passionate about innovation and knowledge sharing, he is dedicated to enhancing infrastructure longevity through advanced engineering solutions.