Welding – a recognised and familiar metal bonding method, but it is not without its issues! Here we look at 4 common problems associated with hot work and how they can be avoided.

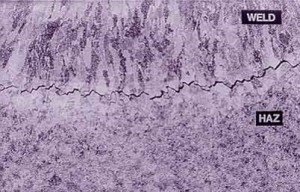

1. HAZ and Stress Relieving

PROBLEM?

The weld itself can cause distortion of the substrate, due to heat. More commonly known as HAZ (Heat Affected Zones), the intense process of heating and subsequent cooling of the substrate can generate weaknesses in the metal and limit the structural integrity at the weld point. In certain applications the metal requires stress relief to ensure that the risk of subsequent changes to the metal is minimised. Dependent upon the heating technique and metals involved, the stresses of hot work can affect both small and large areas, weakening the equipment later in its service life.

SOLUTION!

Heat generated by using a Belzona material as an adhesive between two surfaces does not typically exceed 25C/80F. No heat = no HAZ and no need for stress relieving.

2. Cavities Behind Weld Patches and Brackets

PROBLEM?

A large number of welded patches and brackets will have cavities present. These voids simply represent areas of exposed metalwork, which can lead to the beginning of corrosion complications; displaying initially as pitting, but potentially leading to through-wall defects. Overall, the weld creates limited contact with the metal work, potentially causing the stresses placed upon the weld/repair to focus on a limited area. This increases the likelihood of stress cracking due to uneven expansion and contraction of the substrate.

SOLUTION!

Using Belzona cold bonding ensures a full contact between two surfaces, not only on the edges. Moreover, cold bonding adhesive can conform to irregular shapes and substrates, filling the void between the surfaces. This ensures 100% contact which enhances load bearing capability.

3. Bi-metallic Corrosion

PROBLEM?

The use of filler metals with compositions different from the base material may produce an electrochemical potential difference that makes some regions of the weldment more active. There is a number of common weld

deposit/base metal combinations that are known to form galvanic couples. Even when special care is taken to select the materials, certain environments can worsen the issue. For example, the E6013 welding electrode is known to be highly anodic to A285 base metal in a seawater environment.

SOLUTION!

Belzona products are specifically deigned specifically to combat most types of corrosion. For bi-metallic corrosion to begin, you require 3 components: an anode, a cathode and an electrolyte.

Eliminating the electrical contact between the two materials must be stopped in order to prevent bi-metallic corrosion. Belzona materials are natural insulators of electricity. 100% coverage achieved by a Belzona bond makes certain there is no contact between the metal surfaces. No contact means no bi-metallic corrosion.

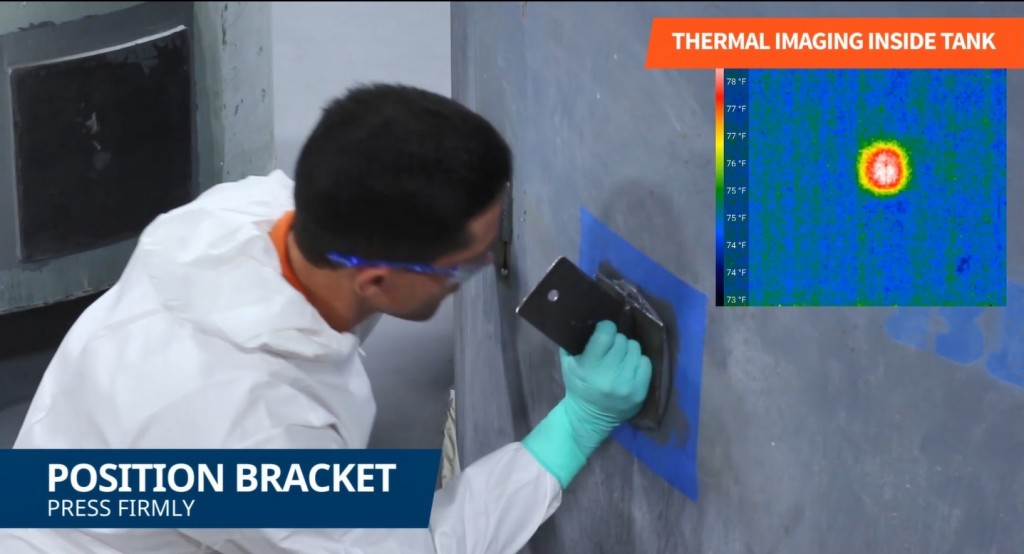

4. Heat Sensitive Coatings and Linings

PROBLEM?

As you can see in this video, when welding a bracket onto a tank, the inside can heat up to in excess of 1600°C/2912°F. This action would surely damage the protective lining, as very few solutions can successfully withstand such temperatures. See how fast the lining deteriorates and begins to smoke.

SOLUTION!

The application of a Belzona adhesive produces heat equivalent to a “room temperature”, up to 27°C/80°F. Such exotherm is perfectly safe for most linings, including Belzona protective linings.

In Summary

Belzona cold bonding can address key issues associated with welding. Obviously, there are situations where welding would still be feasible. Only 10 decades ago, it was still in it’s infancy. Now, it has matured with standards and expertise which ensures precision. Over that time, it has become apparent that hot work is not easily removed from the process. Cold bonding helps to remove this issue from the process, whilst also providing added benefits to the end user, such as no hot work and a reduction in corrosion post-application. With this technology, the 4 main welding problems could be considered solved.

For More Information

Belzona has been championing cold bonding since the introduction of our paste grade materials in the 1960s. For more information about these materials visit belzona.com/composite_repairs

Henry Smith

Senior Technical Service Engineer

Belzona Polymerics Ltd

This is really appreciated that you have presented this data over here, I love all the information shared. It will be very helpful to understand the content on welding . Indeed a great post to share!! Loved it…

Great and awesome post! I appreciate your efforts on writing.

This is awesome!

Sounds interesting,

so is your technology as durable as normal weld seams?

Hello Tony,

Yes, our technology provides excellent durability and demonstrates superior mechanical properties. I invite you to read this webpage http://www.belzona.com/en/products/purpose/metal-repair.aspx to get more familiar with the Belzona technology.

If you have any other questions, do not hesitate to contact us.

Best regards,

Belzona Team

This is awesome! I weld a lot of stair railings for a lot of my clientele, and have some issues with my gear regarding temperature and lining protection. I appreciate you writing this, because this might be the solution for me. glad I came across this.

Thank you for your comment and reading the Belzona Blog!

Belzona Team

Pingback: In Action: Cold Bonding Cell Antennae Mounts - Belzona Blog

Excellent