What Is a Chiller?

A heat exchange or transfer is a unit operation, meaning it is a basic step in most industrial processes. The equipment used to implement this transfer is a heat exchanger, or a chiller. There are various types of chillers in industry, but they all have a common problem: they can suffer from metal loss due to corrosion, erosion, chemical attack, or their combination, and deteriorate over time, hence reducing their lifetime.

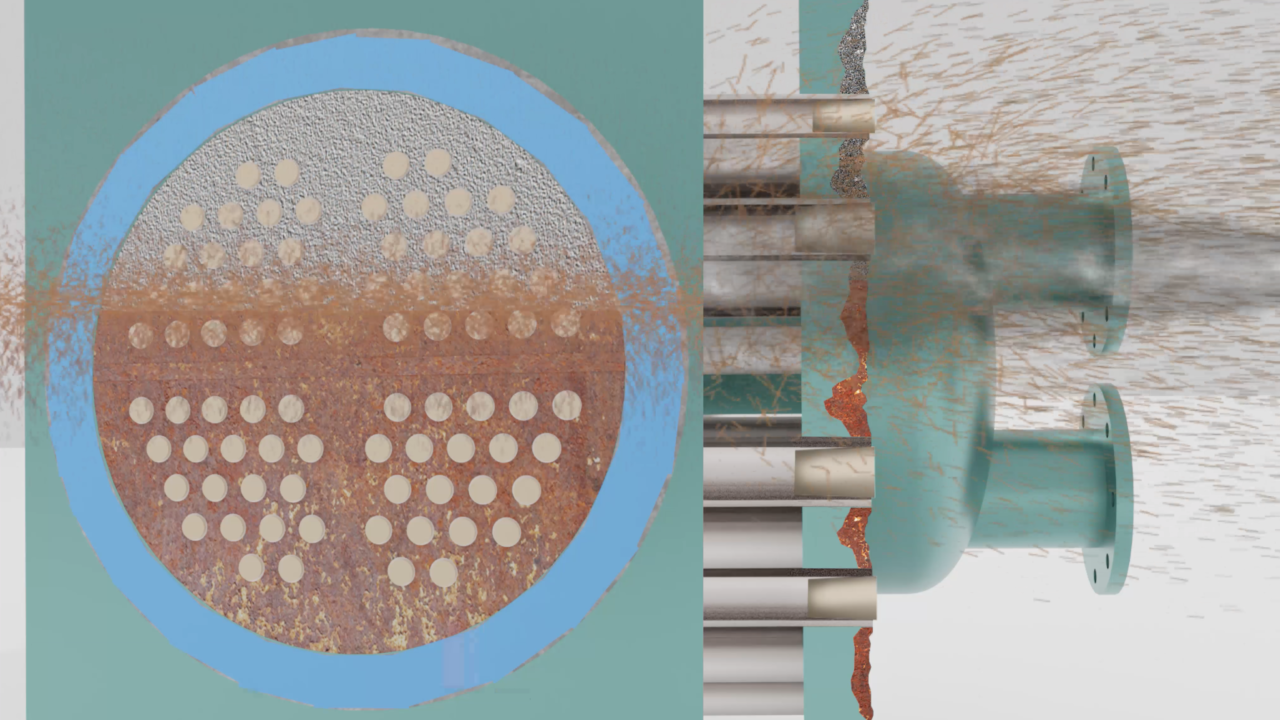

Corrosion in a Chiller

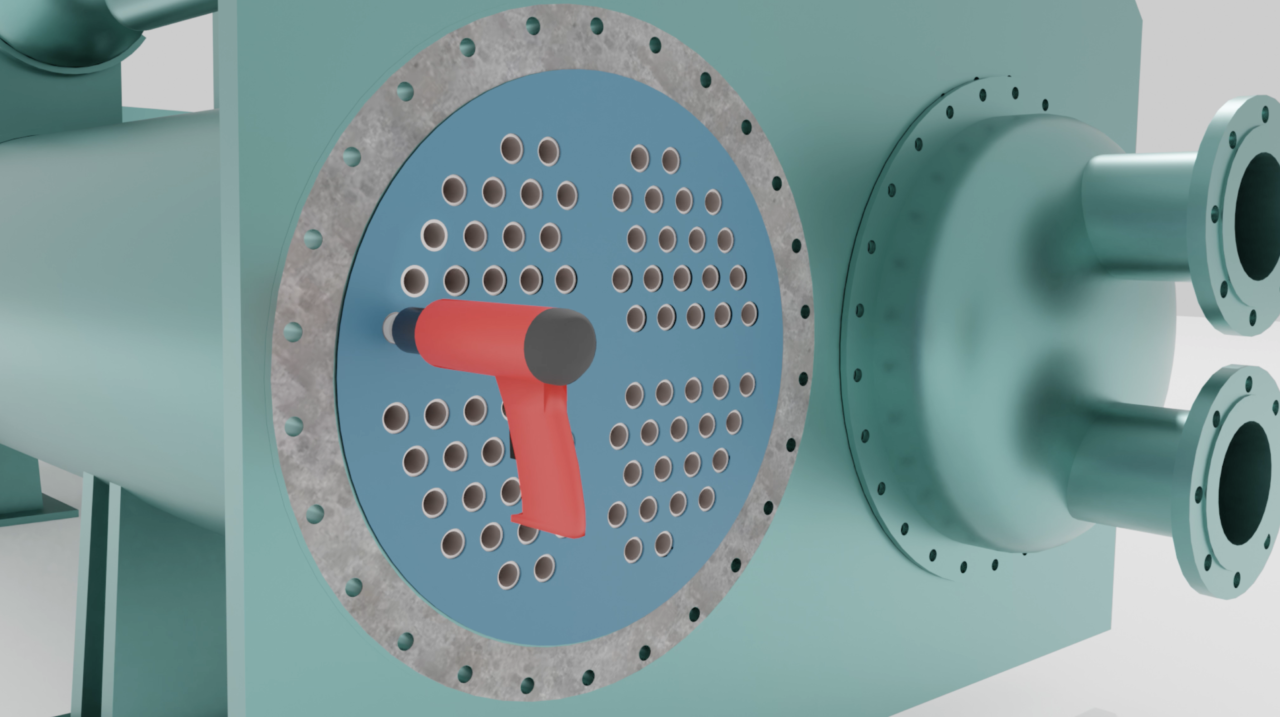

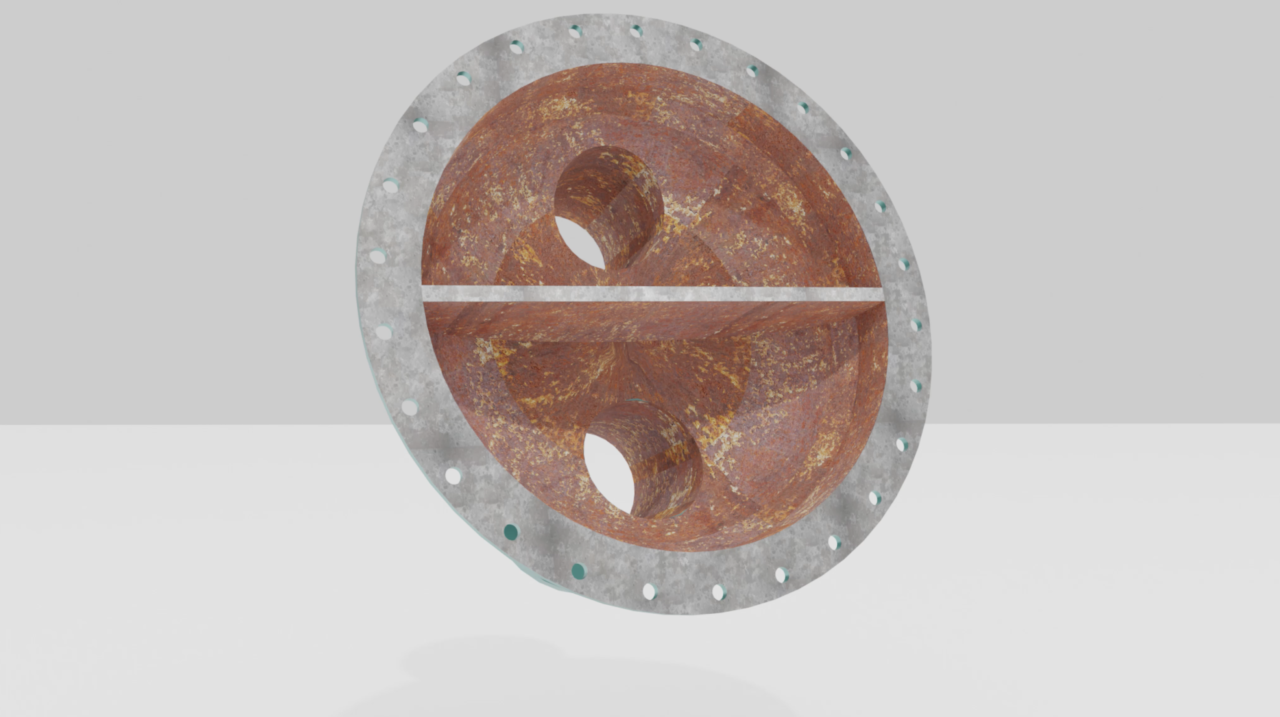

A chiller is a vital part of any heating or air conditioning system. Failure to quickly protect these chillers allows galvanic corrosion to take place, resulting in wastage and metal loss on the tube sheet around the coolant tubes.

Left untreated, the loss of metal can cause leakage of the coolant and contamination of the chilled water. Corrosion is not restricted to the tube sheet, the water box and end covers can also be affected. In particular, corrosion in division bars and seal faces can lead to leakage and loss of efficiency, as well as the inability to maintain the desired working environment in buildings.

Belzona Solutions for Chillers

Belzona solutions have been implemented for many years and throughout the entire world aimed at repairing sections of the chiller including tube sheets, division bars and end covers, using fit-for-service protective coatings, rebuilding materials, and bespoke application techniques.

The Belzona solution not only restores the original tube sheet profile, but also creates a smooth tube sheet face flush with the tube ends, leading to reduced turbulence and greater efficiency. Water boxes and end covers can also be repaired and protected.

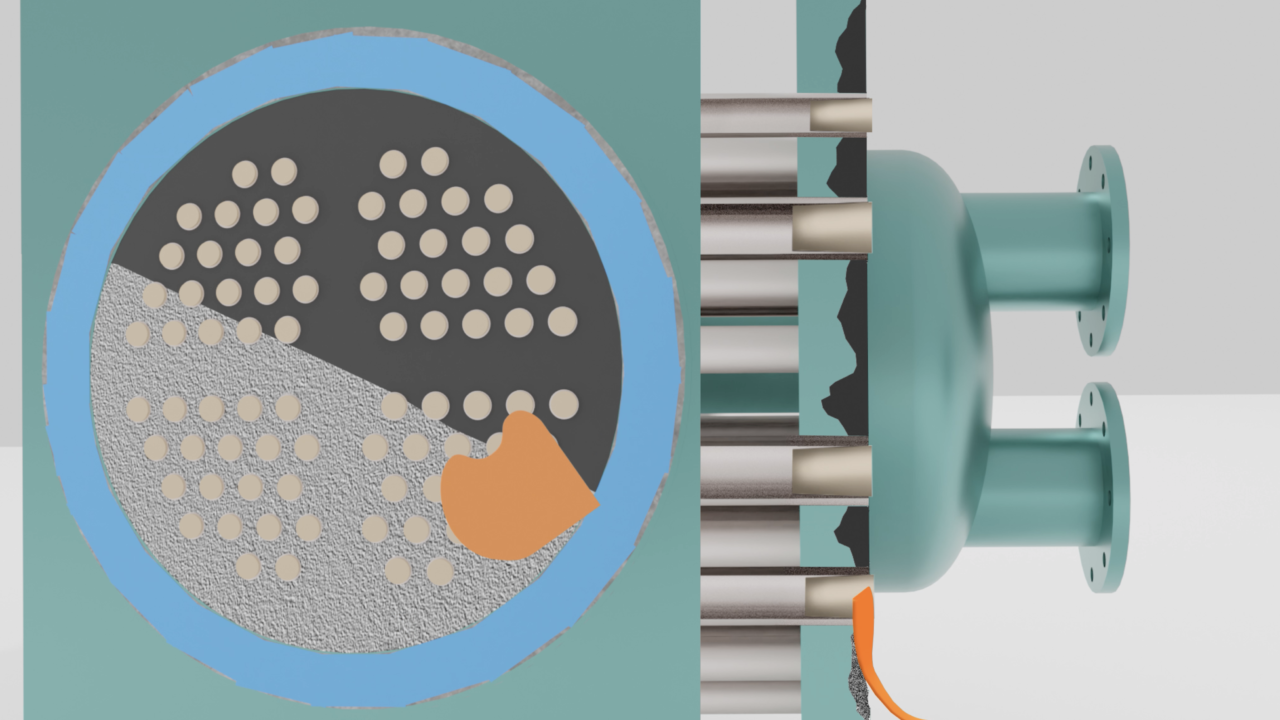

The affected section is rebuilt using Belzona’s two-component repair composites. The paste grade material rebuilds the substrate to its original tolerances, while the coating grade system provides a layer of durable protection. This cold-applied repair process bypasses the need of hot work that would leave the substrate susceptible to further damage.

| Belzona 1100 Series | Belzona 1200 Series | Belzona 1300 Series |

|---|---|---|

| Paste-grade rebuilding and resurfacing materials for in-situ repair of damaged tube sheets. | Fast curing emergency paste-grade rebuilding materials for the rapid repair of metallic parts. | Ceramic filled coatings for erosion-corrosion protection. |

How To Repair a Chiller, a Step-by-Step Instruction

Step 1: Before applying the materials, identify the damaged area, tape it off, and make sure it is deemed mechanically sound.

Step 2: Protect the internals of the tube sheets before any mechanical preparation is carried out. Use tapered corks for this purpose. Level the corks using the most protruding tube as a guide.

Step 3: Prepare the application area by abrasive blasting to an average minimum of a 3 mil (75 micron) profile. Use Belzona 9111 Cleaner/Degreaser to remove all residual blasting debris.

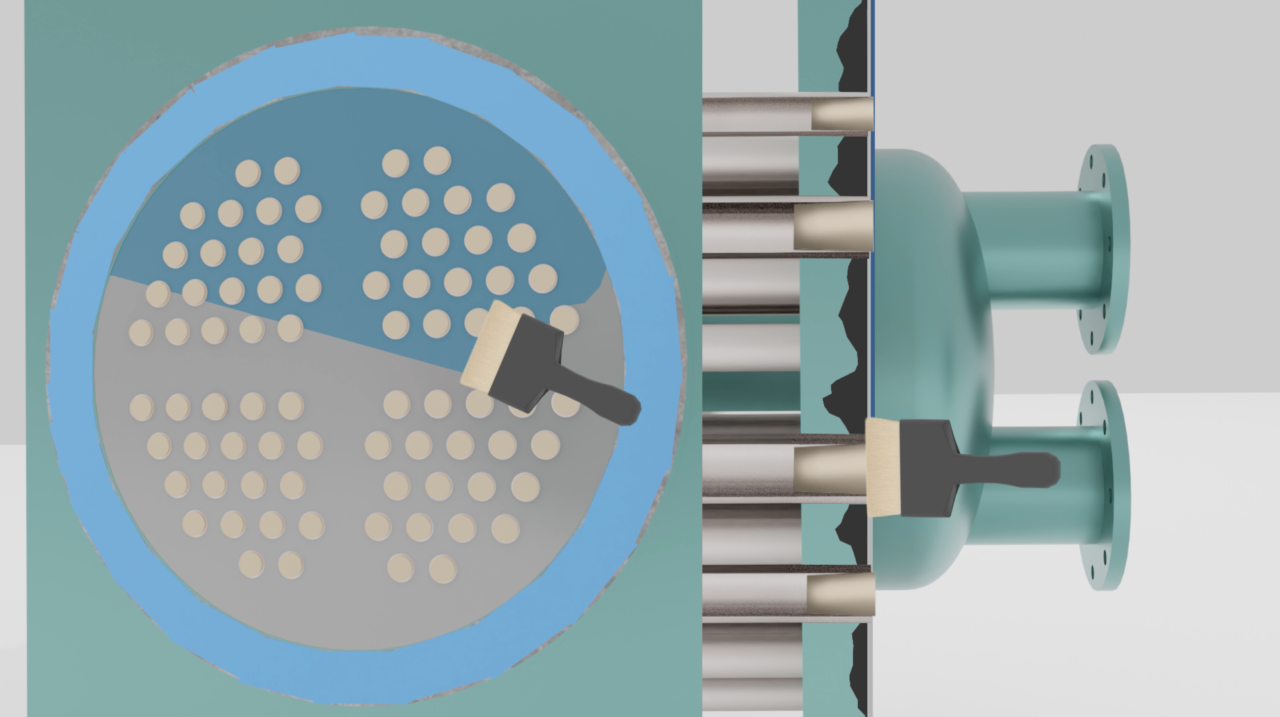

Step 4: Use Belzona 1100 series 100% solids paste-grade materials to rebuild and resurfaced all the eroded and corroded areas. The material can be applied with an applicator. Embed the material well into the surface to make sure all the voids are filled in.

Step 5: Once the rebuilding material has fully cured, apply two coats of Belzona 1300 series ceramic filled coatings for erosion-corrosion protection. Two distinctive colors are applied until the minimum total thickness required is achieved. Remove the tape as soon as the second coat has been applied.

Step 6: Once the applied material has fully cured, remove the corks using a corkscrew or other means. Debur the tube ends using conical grinding stones.

The same procedure can be followed for the repair and corrosion protection of end covers.

For a full video instruction, click on the thumbnail below.

Interested in purchasing Belzona’s repair composites and protective coatings?

Yulia Burova, Marketing Director, Belzona Inc., Miami FL, USA