Maintaining machinery performance and longevity requires proper alignment and support. Chocking and shimming compounds ensure equipment operates efficiently while minimizing vibration, stress, and potential damage.

Shimming Solution

Shimming is the process of filling gaps to achieve the correct fit, alignment, or clearance between components. It is often used to correct manufacturing inaccuracies, compensate for material loss, adjust tolerances, or address deformation caused by long-term service.

Gaps can form for several reasons:

- Wear: Contact between components removes material, while general mechanical wear can distort features like keyways and slots.

- Chemical or environmental degradation: Exposure can break down concrete or metal surfaces, particularly on plinths and support structures.

- Manufacturing or design issues: Imperfections during fabrication or installation can create unintended spacing.

If untreated, gaps can lead to misalignment, poor load transfer, and stress concentrations that increase the risk of equipment failure. Even small gaps can trap moisture, promoting crevice or galvanic corrosion.

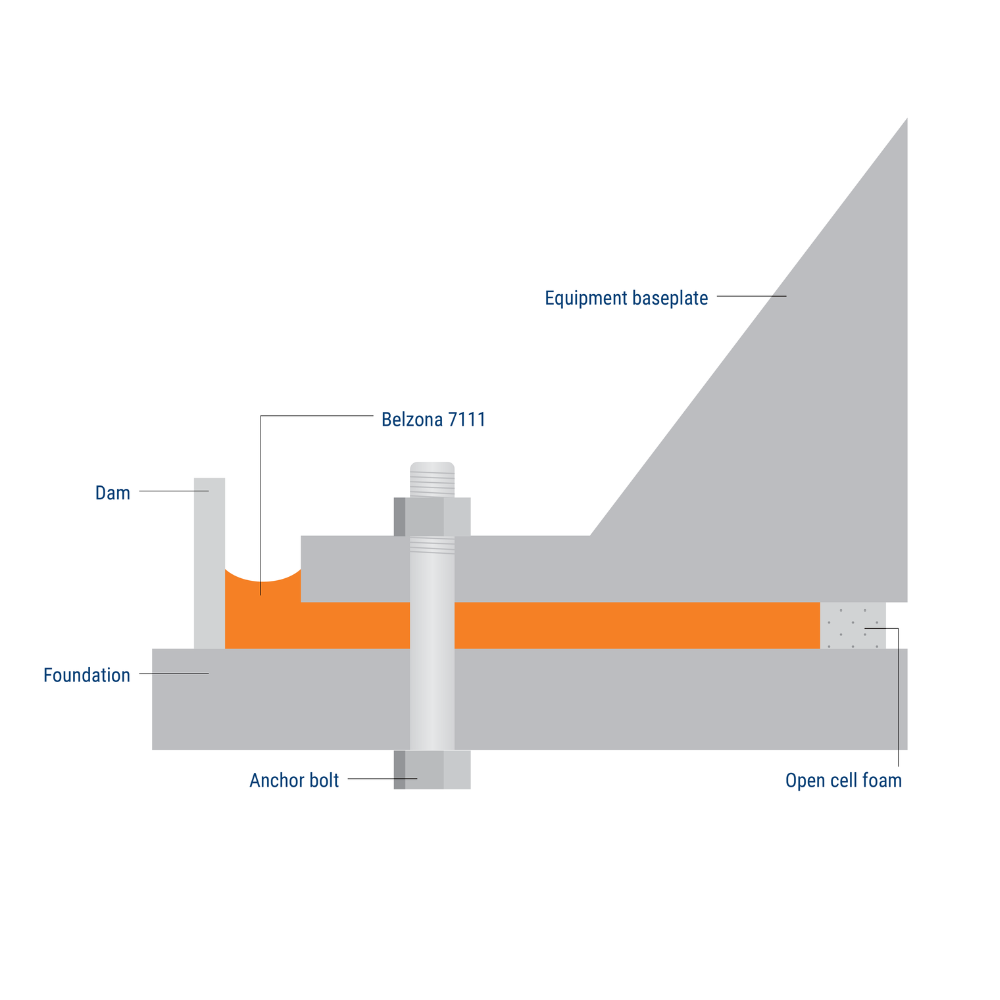

Belzona 7111 can effectively fill gaps while maintaining full contact between components, protecting equipment from wear and corrosion.

Chocking Solution

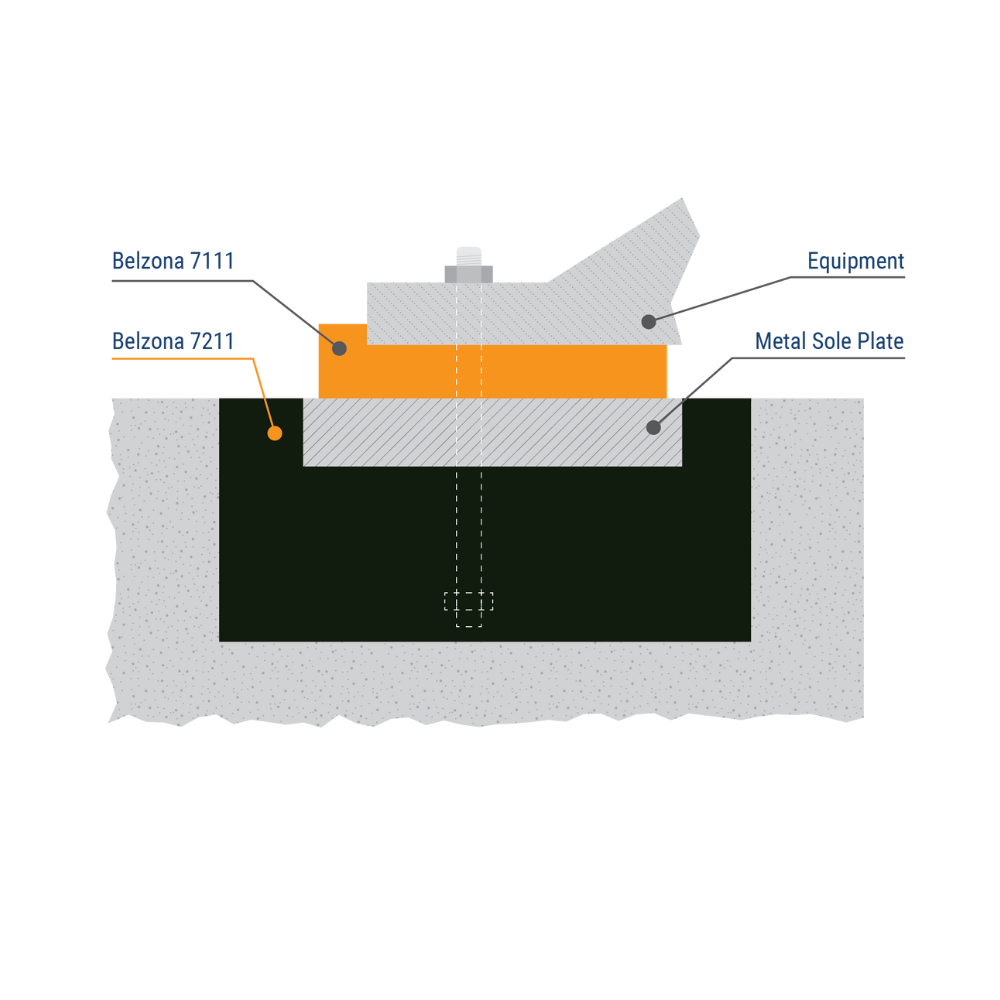

Chocking is a specialized form of shimming that ensures a machinery baseplate becomes a monolithic unit with its foundation. Proper chocking provides complete contact and optimal load transfer, reducing vibration and minimizing mechanical damage.

Large, high-vibration machinery is typically installed on concrete foundations using a chock. Ineffective chocks can loosen over time due to vibration and impact, slackening anchor bolts, and causing misalignment, especially problematic for equipment transmitting significant loads.

Several materials are available for chocking, each with its own advantages. Iron-filled grouts may corrode, while cementitious grouts, although strong in compression, often lack the chemical and impact resistance needed for harsh environments. Pourable polymeric materials, like Belzona 7211, offer strength, durability, and ease of installation, making them ideal for in-situ applications.

Belzona Chocking and Shimming Compounds

Belzona offers a range of high-performance compounds designed to support and protect heavy equipment in demanding industrial and marine environments:

- Belzona 7111 – A pourable, self-leveling chocking, backing, and leveling compound built to absorb physical and thermal shock typical of marine propulsion systems and large industrial machinery. Its high compressive strength and excellent flow characteristics allow it to conform to surface irregularities, ensuring precision alignment and long-lasting structural integrity.

- Belzona 7111 is approved by:

– American Bureau of Shipping (ABS)

– Bureau Veritas (BV)

– Det Norske Veritas (DNV)

– Lloyd’s Register (LR)

- Belzona 7111 is approved by:

- Belzona 7211 – A deep-pour grout capable of supporting up to 8-inch (20.32 cm) depths. This three-component, 100% solids system delivers excellent load-bearing performance, low exothermic reaction, rapid strength development, and superior creep resistance. Its self-leveling properties and customizable flow options make it a versatile solution for anchoring heavy-duty equipment.

Practical Applications for Chocking and Shimming Compounds

Chocking and shimming are broad applications. While chocking targets a specific outcome, creating a monolithic unit between machinery and foundation, it can be considered a type of shimming. Belzona’s approach often uses the original equipment as part of the shimming or chocking operation, allowing for a perfect fit with minimal specialist tools.

Frequently Asked Questions

What are chocking and shimming compounds?

Chocking and shimming compounds are engineered materials used to fill gaps and provide precise alignment and support between machinery and its foundations. They help maintain equipment performance by reducing vibration, stress, and misalignment that can lead to mechanical failure.

What is the difference between shimming and chocking?

Shimming refers to filling gaps to achieve the correct fit or clearance between parts, compensating for wear, manufacturing tolerances, or deformation. Chocking is a specialized form of shimming aimed at creating contact between a machine baseplate and its foundation to optimize load transfer and reduce vibration.

How do Belzona compounds compare to traditional grout or shim methods?

Unlike traditional cementitious grouts, which may lack chemical and impact resistance, and metal shims that require precise machining, Belzona’s polymeric compounds, Belzona 7111 and Belzona 7211, offer excellent chemical resistance, superior load distribution, decreased installation time, and improved long-term performance.

What are the benefits of using Belzona chocking compounds?

Belzona chocking and shimming compounds, Belzona 7111 and Belzona 7211, provide reliable load transfer, resist physical and thermal shock, reduce vibration, and help maintain alignment over time. Their pourable and self-leveling properties allow them to conform to surface irregularities and create durable support structures even in demanding industrial and marine conditions.

Learn More

Marine Coatings and Composites: Six Key Maintenance Areas

How to Repair Cavitation Damage on Boats

Diesel Engine Repair on a Passenger Ferry

Contact Belzona for More Info About Chocking and Shimming Compounds

Digital Content Creator, Belzona Inc., Miami, Florida