Decks, Tanks, Pipes and Fittings Protected with Polymeric Cold Bonding Compound

Polymeric cold bonding solutions are being deployed throughout the Oil and Gas Industry as an alternative to welding. With epoxy cold bonding compounds, the installation and maintenance of assets such as decks, tanks, pipes and fittings, can be safely and easily carried out in situ without the need for hot work. A versatile solution, epoxy cold bonding is equally effective at the fabrication stage, during turnarounds or whilst the platform is in operation.

The following two case studies showcase Belzona’s cold bonding epoxy materials being deployed in riser housings and on an offshore platform deck.

111 Riser Bearings Protected Against Abrasion with Epoxy Paste and Ceramic Epoxy Coating

A new build central processing facility constructed in South Korea, had risers and riser housings in need of protection. When stationed, risers move inside the housings, creating abrasion and exacerbating corrosion. The decision was made to protect these areas with composite bearings. As the bearings had a design life of 40 years, the Client required a method of attaching these bearings securely and turned to Belzona to provide a solution.

Belzona worked together with the Client from the conceptual phase to the execution of the project – delivering a complete technical package. This included the design, product selection and work procedure, as well as on-site support and inspection.

Specification of Corrosion-Resistant Materials

A high-performance system was specified that would provide protection against the effects of abrasion and corrosion for the long-term. In addition, this would also act as a robust adhesive to secure the pads without the need for mechanical fixings.

A combination of Belzona 1111 (Super Metal) and Belzona 1321 (Ceramic S-Metal) were specified.

Belzona 1111 is a multi-purpose, durable epoxy repair composite based on solvent-free epoxy resin reinforced with silicon steel alloy. Designed for metal repair and resurfacing applications, Belzona 1111 will not corrode and will provide no shrinkage, expansion or distortion.

Belzona 1321 is a ceramic epoxy designed to provide an outstanding level of erosion and corrosion resistance to metal surfaces whilst also acting as a tough adhesive compound. Providing a proven long-term bond between the dissimilar materials, Belzona 1321 can be applied at various thicknesses allowing the adhesive to also act as a shim. This provides a final opportunity for optimum alignment during the construction process. Its high adhesion levels to various substrates and high compressive strength allow for the even distribution of loads across the entire bearing surface.

The abrasion and corrosion-resistant properties of these systems would thoroughly fortify the bearings, ensuring that the risers and riser housings were protected for the long term.

Application Procedure

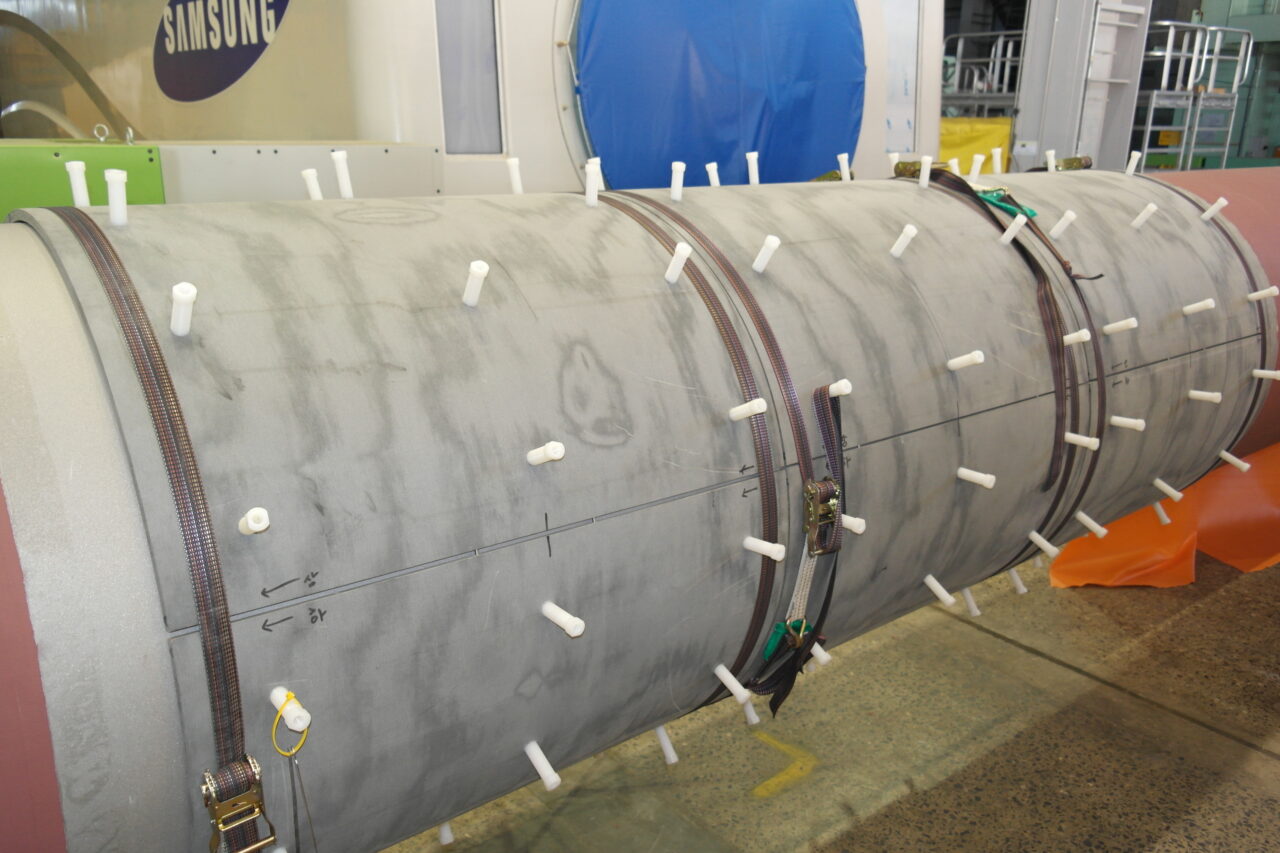

A total of 84 risers and housings were completed on the hull side and 27 on the topside. As the bearings reached 2.5m diameter and 3m length, they were split into 16 sections and had to be bonded in place. The bearings were aligned in place using jigs, straps and injection port bolts. The bearing had to be jacked to 4mm from the substrate and the seams were then dammed using Belzona 1111.

Following this, Belzona 1321 was injected through the injection ports. Once cured, the injection ports were cut off, filled with Belzona 1111, and ground flush.

Cold-Curing Epoxy Materials Successfully Bypass the Need for Hot Work

The epoxy materials facilitated a fast and seamless application, helping to keep downtime to an absolute minimum. Furthermore, the cold-curing properties of the Belzona systems bypassed the need for hot work and ensured that the application could be carried out safely.

Epoxy Paste and Epoxy Injection Systems Fortify Platform Laydown Deck

Through daily operation and weather, an 8mm steel deck on an oil and gas platform in the North Sea had become severely corroded. A reinforcement plate was required to repair the substrate and protect it from further corrosion. As welding was not an option due to the under-deck passive fire protection system in place, the Client sought an alternative bonding solution.

Specification of Epoxy Systems

A combination of Belzona 1111 (Super Metal) and Belzona 5811 (Immersion Grade) were specified.

The epoxy paste, Belzona 1111 was chosen for its high strength, corrosion-resistant properties while the epoxy coating, Belzona 5811 was specified for its ability to provide long-term corrosion protection for equipment operating under harsh environments.

The combination of these systems would ensure that the laydown deck would remain protected for the long term within the highly corrosive environment.

Application Procedure

Firstly, steel plates, drilled to accept jacking bolts and injection ports, were prepared and positioned onto the grit blasted deck. The jacking bolts were used to obtain accurate levels. The sides of the plates were then dammed using Belzona 1111. Following this, Belzona 5811 was then injected into the void using a standard airless spray pump to seal and bond the reinforcement plate to the deck, achieving full contact.

Cold Bonding Method Provides Equivalent Strength to Plates Bonded via Welding

Independent testing showed that the Belzona bonding method was equivalent in strength to a welded plate. The independent Engineering Designers reported that the installation was: ‘Robust enough to withstand the rigours of the laydown area operations.’

In addition to providing a hard-wearing solution, the application was carried out without any disturbance being caused to the daily operations of the site; nor was the passive fire protection in the machinery space below affected.

Testament to the long-term, corrosion-resistant capabilities of Belzona polymeric systems, this application was inspected 11 years after its installation and was found to be in perfect condition.

Cold Bonding: The Safe and Reliable Alternative to Welding

While welding is one of the most recognised bonding techniques, it is not without its limitations. It can present several challenges related to personal and environmental safety, downtime and defects that can lead to failures.

By deploying Belzona’s cold bonding compounds, engineers and maintenance teams can avoid these issues while still achieving a hard-wearing and long-term repair and protection solution. This makes Belzona’s polymeric systems a safe and reliable alternative to welding.

Want to Learn More about Cold Bonding Polymeric Repair and Protection Solutions?

Click here to read Earl Brown’s blog post about how Belzona 1111 (Super Metal) and Belzona 1161 (Super Metal UW) were used to bond steel or composite attachment plates to water storage tanks, rooftops and various other structures used for 5G antennas.

For a closer look at conventional welding vs. cold bonding, Henry Smith’s blog post discusses the top four common problems associated with hot work and how they can be avoided by deploying Belzona cold bonding technology.

Watch this Space: New Fatigue Resistant Adhesive Set to be Launched…

On the first of November, Belzona will be launching a brand new fatigue resistant adhesive that is designed to be cold-applied in a variety of application areas such as equipment support brackets, plate bonding, handrails and more. This product offers an alternative to mechanical fastenings/fixings and is a viable alternative to welding.

Be sure to subscribe to the Belzona Blog using the form below to learn all about it!

Interested in purchasing Belzona’s repair composites and protective coatings?

Chloe Hirst is the Senior Copywriter at Belzona Limited and is based in Harrogate, England. She gained a Bachelor’s Degree (with Hons.) in Media and Communications (specialising in Journalism) at Goldsmiths College, University of London. Chloe regularly writes case studies and thought leadership content featuring a variety of different industries, with a special focus on the renewables sector. In both 2023 and 2024, she won the Best Manufacturing Content Creation Specialist (UK) Award as part of Acquisition International’s Influential Businesswoman Awards.