Belzona Rubber Repair for Floating Hoses

Cold-curing elastomers offer an alternative solution for floating hose repair. Asset owners can carry out repairs without the need for specialist tools, thus eliminating the need for hot work. This ensures a fast return-to-service, whilst offering a versatile repair with durability and elasticity.

Cold-curing elastomers offer solutions for a range of marine and industrial applications. These cold-cure polyurethane materials are suitable for marine floating hoses, offshore loading/discharge hoses, floating dredge hoses, floating oil hoses, submarine mainline LPG hoses, FPSO floating hose repairs as well as rubber fenders and other rubber components of equipment used across various industries.

Asset owners can select Belzona elastomers based upon the nature and severity of the damage on the rubber components, the level of urgency, the system pressure and operating temperature. The following table provides guidance on how to select products to repair damaged rubber components.

| MAIN SYSTEM REQUIREMENT | Belzona 2111 (D&A Hi-Build Elastomer) | Belzona 2211 (MP Hi-Build Elastomer) | Belzona 2311 (SR Elastomer) |

| Rebuilding-grade | YES | YES | YES |

| High abrasion resistance | YES | ||

| General repairs | YES | ||

| Rapid repairs | YES |

Belzona Elastomers: Put It to the Test

Belzona has put a range of our cold-cure polyurethane materials to the test to assess their superior performance for repairing and protecting rubber components.

- Quick Return-to-Service: Belzona solutions allow applications in situ, meaning it is less time consuming for disassembling equipment. In addition, for emergency repairs, Belzona 2311 (SR Elastomer) can achieve full mechanical cure in 50 minutes at 25°C (77°F).

- Excellent Adhesion: Belzona elastomers can adhere to a variety of substrates. Apart from rubber, they can adhere to concrete and steel. Their excellent adhesion properties ensure long-term repair and protection.

- Flexibility: During operations, equipment is subject to extensive tensile and tearing forces. When tested in accordance with ASTM D412, Belzona elastomers demonstrate outstanding elongation properties. For example, Belzona 2211 (MP Hi-Build Elastomer) exhibits elongation of up to 1000%. Belzona 2111 (D&A Hi-Build Elastomer) exhibits elongation of up to 550%.

- Abrasion and Impact Resistance: Belzona carried out in-house testing to measure the abrasion resistance of its highly abrasion resistant materials. The testing confirms the durable repairs and long-term protection that Belzona elastomers can offer.

- Application Versatility: Belzona elastomers are versatile, applicable for various repair scenarios and environments. Belzona elastomers are easy to mix and apply, and are able to adhere to a variety of substrates. These cold-cure polyurethane materials provide effective solutions for industrial maintenance.

Step-by-Step Guide: How to Repair Damaged Rubber on a Floating Hose with Belzona Elastomers

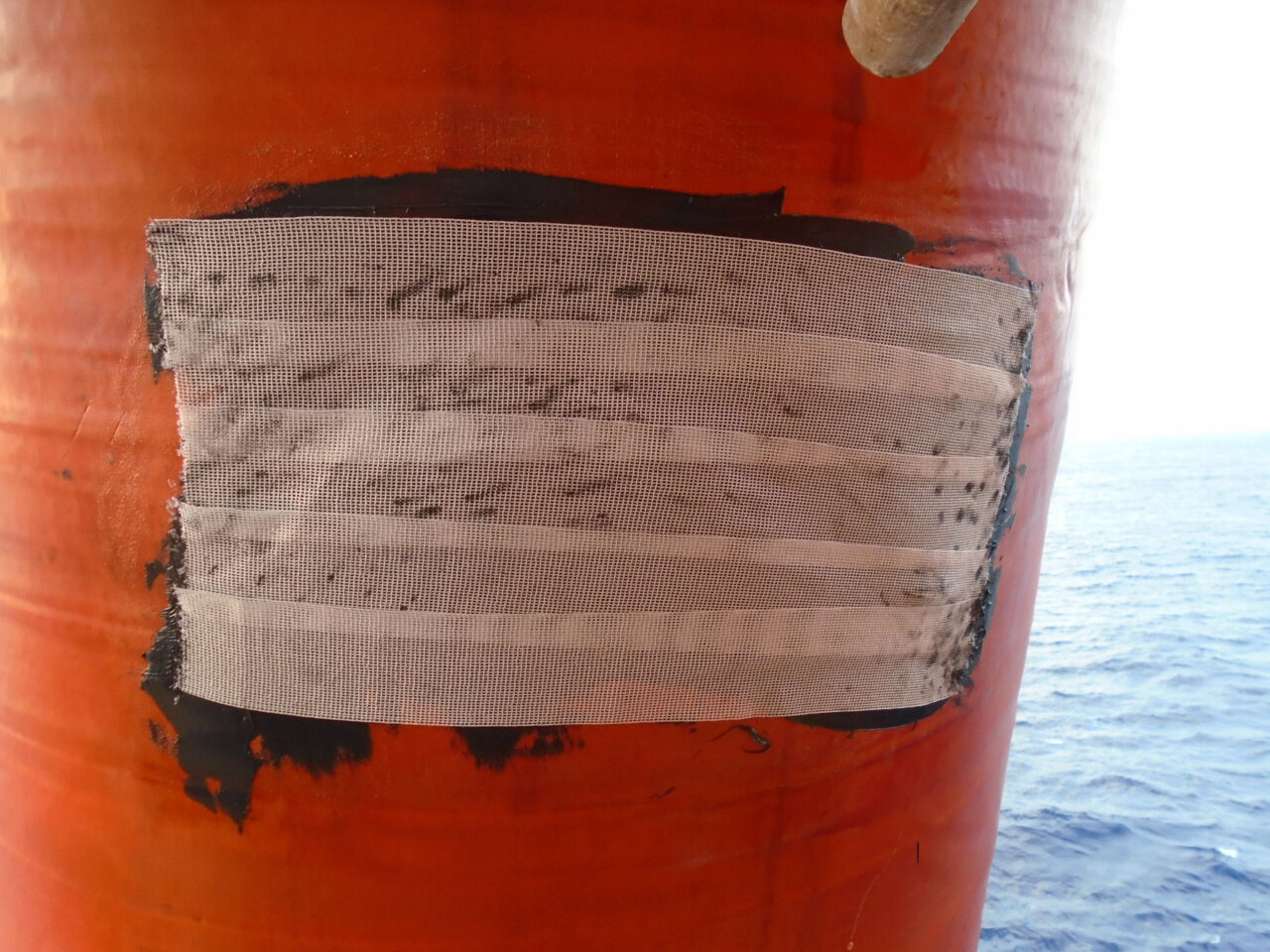

In this blog, we demonstrate how to use Belzona 2211 (MP Hi-Build Elastomer) to repair damaged rubber on a floating fuel hose. The damage on the rubber was due to collisions from ship propellers during fuel loading.

Step 1 – Terminate the Tear on the Damaged Hose

Use a sharp knife to create a sound edge terminated square or undercut on the floating hose.

Step 2 – Remove Loose Material from the Floating Hose

Cut away all loosely adhered material on the floating hose and provide an undercut surface. If required, use pliers to help pull the damaged rubber and aid in the undercut. If there is wet reinforcement fabric underneath, allow it to dry before proceeding to further steps.

Step 3 – Prepare the Surface before Applying Belzona Elastomers

Use a rotary wire brush or Belzona roughing brush to abrade the area of damage, the undercut surfaces, and the perimeter of existing, sound substrate until a woolly finish is achieved. Then, brush away loose contamination and use an appropriate cleaner or degreaser to clean the area. Belzona recommends consulting the Instructions for Use for an appropriate selection of cleaner or degreaser.

Step 4 – Define the Repair Area

Use masking tape to define the repair area. This step ensures a clean finish after the application is completed.

Step 5 – Apply Conditioner Over the Repair Area

Apply a thin layer of Belzona 2911 (Elastomer QD Conditioner) or Belzona 2921 (Elastomer GP Conditioner) to condition the repair area. The suitability of the conditioner depends on the substrate and application environment. Belzona recommends consulting the Instructions for Use or contacting an authorised Belzona Distributor for further guidance regarding conditioner selection.

Step 6 – Mix and Apply the Product

Mix Belzona 2211 (MP Hi-Build Elastomer) until the material is of an even colour and consistency. Wet out the appropriate length of Belzona 9341 (Reinforcement Tape) with the mixed Belzona 2211 (MP Hi-Build Elastomer) and apply this to the repair area.

Step 7 – Rebuild Profile of the Floating Hose

Contour Belzona 2211 (MP Hi-Build Elastomer) to the correct profile using a Belzona applicator.

Step 8 – Remove the Tape

Once the application is completed and the product covers all the repair area, remove the tape and allow the product to cure.

Video: How to Repair Damaged Rubber on Floating Hoses with Belzona Elastomers

Frequently Asked Questions

What are the common causes of damage to rubber components on floating hoses and offshore components?

Rubber components on floating hoses and other offshore devices are exposed to wear and tear during operations. Damage often results from boat impacts or nearby ship propellers gouging chunks out of the materials and leaving deep scores during the fuel loading and unloading operations. Such damage can jeopardise the performance of floating hoses – potentially leading to submersion of the hose line, operational disruptions, and environmental impacts.

What is vulcanisation and are there any drawbacks of using the vulcanisation method for restoring rubber damage on offshore devices?

Vulcanisation is the most traditional rubber repair technique across industries. This rubber repair method involves heat and pressure for a strong chemical bond. Although vulcanisation offers a long-lasting solution, this rubber repair method relies on very specific environmental conditions and equipment. Moreover, vulcanisation requires time for a specialised crew and equipment to travel on site, leading to long shutdowns.

What types of floating hoses can Belzona elastomers repair?

Belzona elastomers can repair a wide range of marine or offshore floating hoses, including those from Yokohama Seaflex Series, Dunlop marine hoses, and Trelleborg hoses. Whether the hose is part of a Single Point Mooring (SPM), Ship-to-Ship (STS) transfer, or terminal offloading system, Belzona offers a cost-effective solution that extends service life and reduces downtime.

Can Belzona elastomers be used on other offshore assets besides floating hoses?

Yes, Belzona elastomeric materials can repair and protect other offshore and marine assets. This includes Belzona 2141 (ACR-Fluid Elastomer) which is a fluid grade for coating surfaces requiring cavitation and erosion resistance. This fluid-grade elastomer is suitable for pipes, Kort nozzles, turbines, impellers, propellers, valves, and rudders, amongst others.

Learn More

- How to Repair Conveyor Belts with Belzona Elastomeric Polymers

- Rebuilding Damaged Industrial Cables Using a 3D Former

- How to Prepare a Rubber Surface for Belzona Applications

Contact Your Local Distributor to Learn More About Belzona Solutions for Floating Hoses

Based in the Company’s Headquarters in Harrogate, Angus Jackson joined Belzona Ltd in 2024 as a Chemical Engineer. Specialising in repair composites and protective coatings, Angus works closely with Belzona’s authorised Distributor Network, providing technical support and training.

He plays a key role in helping select and apply advanced polymeric materials for asset protection, ensuring long-term performance and reliability. In addition to delivering product training, Angus is actively involved in troubleshooting and optimising solutions for corrosion, erosion, and mechanical damage in industrial systems.

Holding an MEng in Chemical Engineering from Newcastle University, Angus has a background in pipeline engineering and simulation, with expertise in hydraulic analysis for Oil & Gas, water, and wastewater systems. His experience in flow dynamics and system optimisation provides a strong technical foundation for his current work in materials engineering. Passionate about innovation and knowledge sharing, he is dedicated to enhancing infrastructure longevity through advanced engineering solutions.

Thank you for valuable information.