Introduction to Conveyor Belt Damage

With over seven decades of experience in mining solutions, Belzona highlights the top five areas where damage is most prevalent in the post – Mining and Quarrying: Belzona’s Top 5 Application Areas. Damaged rubber components and equipment are among the critical issues in the mining industry, usually found in the conveyor systems. In this blog post, we focus on how to repair conveyor belts with Belzona elastomeric polymers.

Belzona 2000 Series for Rubber Repair and Protection

Belzona 2000 Series, cold-cure polyurethane materials, offer alternative solutions for rubber repair and protection. By using these cold-cure materials, asset owners can carry out conveyor belt repairs in situ, without the need for specialist tools, thus eliminating the need for hot work and minimizing downtime. This ensures a fast return-to-service. Moreover, they offer a versatile repair where durability and elasticity, as well as good abrasion and tear resistance, are required.

Belzona 2311 (SR Elastomer) for Conveyor Belt Repair

In the following section, we demonstrate how to use Belzona 2311 (SR Elastomer) to repair a ripped conveyor belt. Belzona 2311 (SR Elastomer) is a two-component, rapid-curing elastomeric polymer for emergency and permanent repair. The solution provides outstanding protection against wear, impact, and abrasion. Asset owners can perform repairs directly on conveyor belts without the need to disassemble them, ensuring minimal disruption to operation.

Step-By-Step Guide: How to Repair Conveyor Belts with Belzona 2311 (SR Elastomer)

STEP ONE

Terminate the tear by drilling holes at each end of the tear.

STEP TWO

Undercut the defected area with a sharp knife to leave a sound edge.

STEP THREE

Remove the top layer of the defined area on the conveyor belt.

STEP FOUR

Abrade the surface with a rotary wire brush or a suitable roughing tool to achieve a woolly finish.

STEP FIVE

Brush away any loose contaminants on the conveyor belt.

STEP SIX

Cover the underside of the tear with a pre-cut tape to prevent the products from leaking through the hole.

STEP SEVEN

Define the area on the conveyor belt using a tape.

STEP EIGHT

Apply Belzona 2911 (Elastomer QD Conditioner) to the repair area.

STEP NINE

Once Belzona 2911 (Elastomer QD Conditioner) is touch dry, start mixing Belzona 2311 (SR Elastomer). Note that Belzona 2311 (SR Elastomer) has a short working life so Belzona recommends strictly following the Instructions for Use for optimal results.

STEP TEN

Use the Belzona applicator to apply Belzona 2311 (SR Elastomer) on the targeted repair area.

STEP ELEVEN

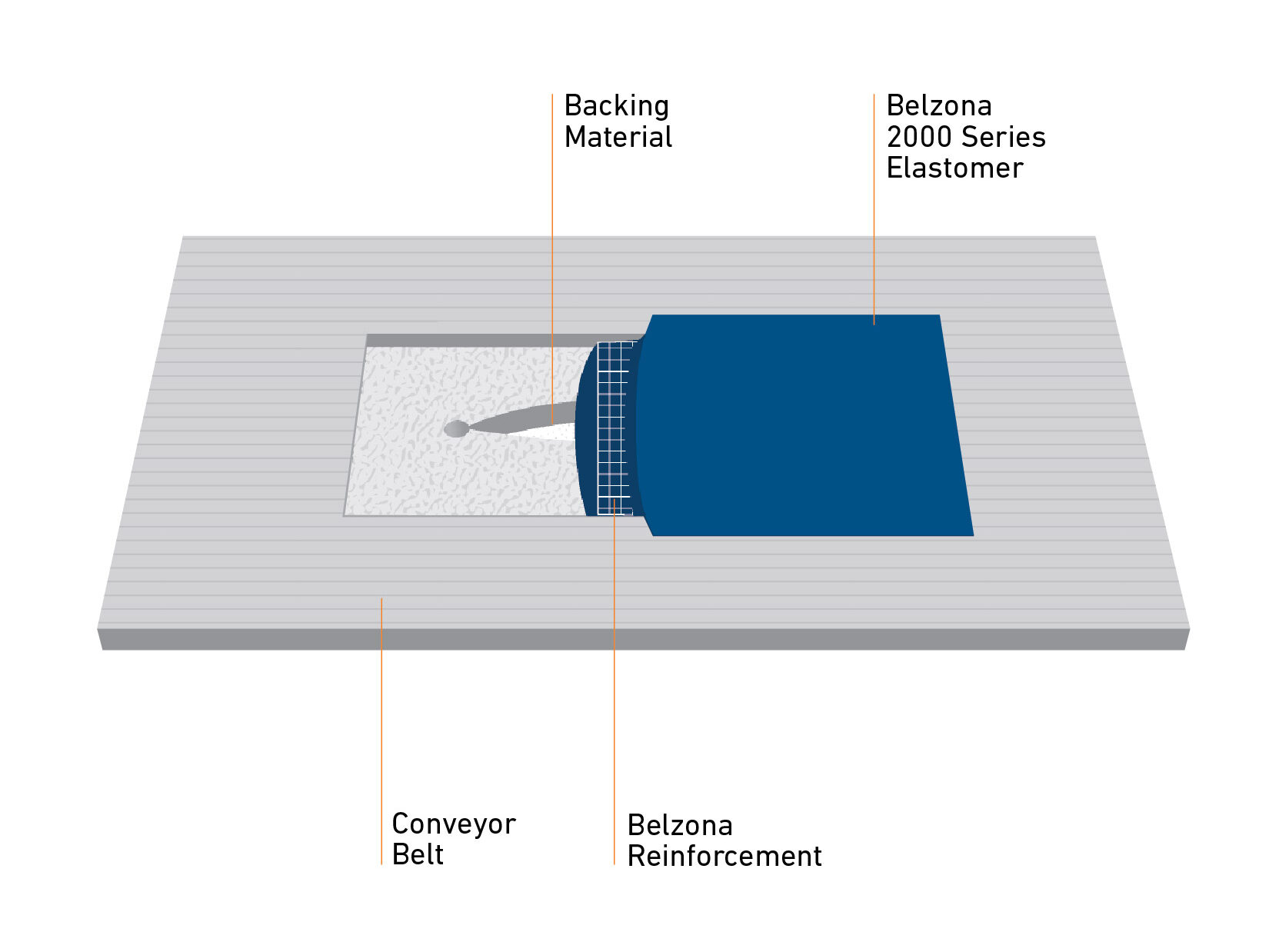

Wet out Belzona 9341 (Reinforcement tape) with Belzona 2311 (SR Elastomer) and embed the tape into the repair area.

STEP TWELVE

Encapsulate the tape with the remaining Belzona 2311 (SR Elastomer) system.

STEP THIRTEEN

Once the product is cured, remove the tape. Now, the application is complete.

Video: How To Repair Conveyor Belts with Belzona 2311 (SR Elastomer)

Learn More

Apart from the repair solutions for conveyor belts, Belzona also offers elastomeric polymer solutions to an extensive range of engineering problems and repair situations.

- How to Repair Damaged Rubber on a Floating Hose with Belzona

- How to Repair a Tire Sidewall Damage

- How to Repair and Fix a Mooring Buoy with Belzona 2111 (D & A Hi-Build Elastomer)

- How to Install a Full-Face Flange Gasket with Belzona 2111 (D & A Hi-Build Elastomer)

FAQ

What is the cure time of Belzona 2311 (SR Elastomer)?

Belzona 2311 (SR Elastomer)is a rapid-curing system, making it suitable for emergency repair. The cure time depends on temperature and operating conditions. At 86°F (30°C), it reaches full mechanical and thermal loading within 40 minutes. In different environments, the cure time will vary. Belzona recommends carefully following the Instruction for Use for optimal results.

Are there other Belzona elastomeric materials that can repair conveyor belts?

Other hi-build elastomers in Belzona 2000 Series can be an option. The suitability of products depends on the hardness of the rubber components. If the repair is urgent and the conveyor belts need to be back in service within a minimal timeframe, Belzona 2311 (SR Elastomer) would be an ideal option given that it is a rapid-curing system for multipurpose applications.

Interested in Belzona Rubber Repair and Protection?

Natalija Skrlec joined Belzona in 2022; since then she has been promoted to the position of Technical Service Engineer based at the Company’s Headquarters in Harrogate. Her main responsibilities involve delivering technical application support and hands-on training in English and German speaking markets.

She graduated with a master’s degree from the University of Ljubljana in Slovenia in 2009 and holds an AMPP (NACE) Coating Inspector Level 1 certification.

Through her technical knowledge and hands-on experience, Natalija supports the application of Belzona’s polymeric solutions across multiple industries worldwide. She is passionate about continuous knowledge exchange, and believes it is the key to engineering excellence and Distributor success.