Within time, water tanks and secondary systems can corrode due to the water, high moisture environment, and corrosive solutions such as chemicals. In addition, deteriorated equipment and structures may lead to leaching, leaks, and environmental damage. However, applying a water tank lining can prevent the listed issues and more.

Benefits of Water Tank Linings

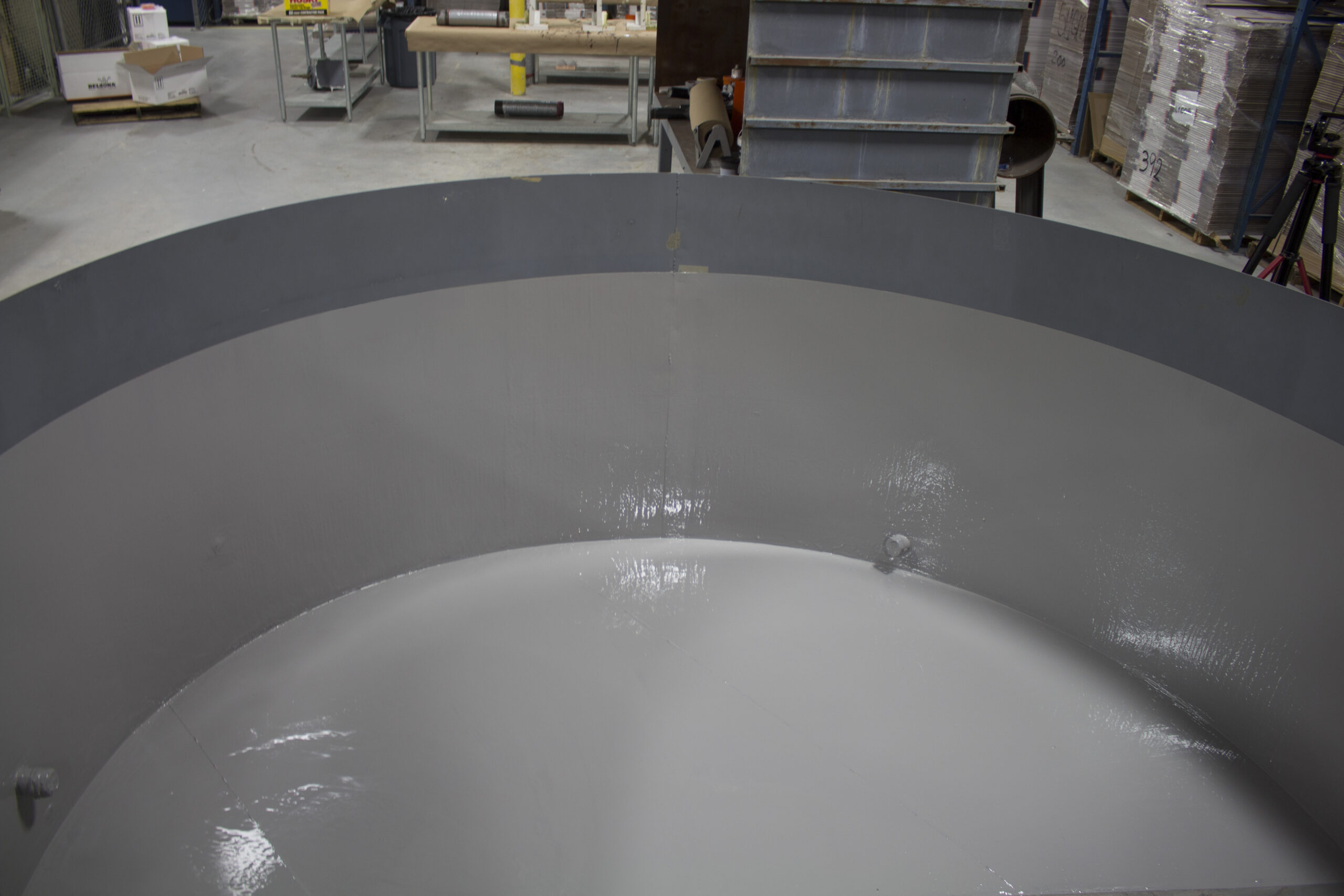

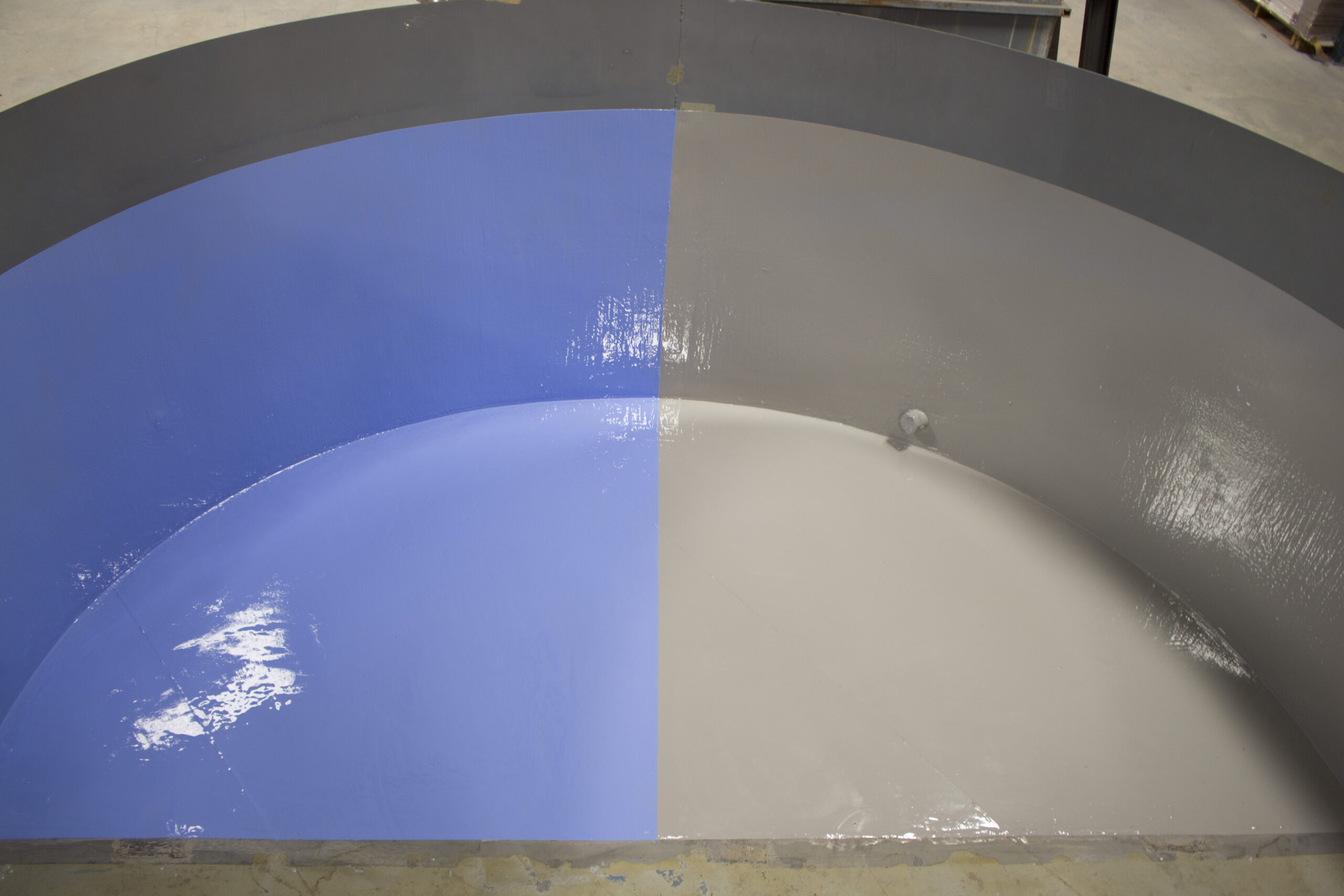

A water tank lining is a coating that will create a barrier between the tank’s substrate and the stored water or aqueous solutions. The barrier is chemical-resistant and corrosion-resistant; therefore, it prevents the common issues presented by corrosion. There are water tank lining coatings that are certified safe for contact with potable water. These coatings do not contaminate the water, making them safe for human consumption. Furthermore, the coatings are solvent-free and require no hot work or welding, adding to their safety.

Step-by-Step Guide to Applying Water Tank Lining, Belzona 5812 DW:

- Brush away loose contamination and clean with a rag soaked in Belzona 9111 (Cleaner/ Degreaser).

- Abrade the surface to give the necessary minimum depth profile of 3 mils (75 microns).

- Transfer the entire contents of the Solidifier container into the Base container to mix large quantities of the material.

- Mix 2.6 parts Base to 1 part Solidifier by volume or 4 parts Base to 1 part Solidifier by weight for small quantities.

- Mix thoroughly together to achieve a streak-free uniform material.

- Belzona 5812 DW can be applied using a stiff-bristled brush or a rubber squeegee to the recommended coverage rate.

- A second coat can be applied, if needed, after the minimum overcoat time of 4 hours at 72°F (22°C).

- Allow the application to dry. The mixture will solidify under cold conditions down to a temperature of 41°F (5°C). However, solidification time is dependent on ambient temperatures. The lower the temperature, the longer the solidification time.

Additionally, some epoxy coatings for water tanks, such as Belzona 5812 DW, can be applied using sprays. It can be applied in suitable areas using a heated airless spray. The typical setup would be a 63:1 airless spray unit with either an in-line heater or trace heated lines capable of raising the product temperature to 122°F (50°C). A solvent must not be added.

The product can be spray- or brush-applied onto metallic surfaces, concrete, brick, and others, offering effective protection of equipment operating under immersion conditions from corrosion damage. The water tank lining repairs clarifiers, tanks, internal and external pipework, valves, fittings, water boxes, utility holes, and cooling tower pans in contact with potable water.

Digital Content Creator, Belzona Inc., Miami, Florida

This article clearly explains how water tank linings help prevent corrosion, leaks, and contamination. The step-by-step application guide is very informative, and highlighting potable-water-safe coatings adds great value. A useful read for anyone looking to extend tank life while ensuring safety, durability, and environmental protection.

“Fantastic guide! The step-by-step instructions and video made it so much easier to understand how to properly apply a water tank lining. It’s great to see such clear, practical tips that can help prevent leaks and extend the life of the tank. Thanks for sharing this valuable resource—definitely bookmarking it for future reference!”

Thank you so much for your positive feedback! We are glad that the Guide was helpful for you! Best regards, Belzona Marketing Team