In the power industry, Sulphur hexafluoride (SF₆) is widely used as an insulating gas in high-voltage equipment, but SF₆ Circuit Breakers Leakage is a critical issue when it comes to switchgear maintenance or SF6 breakers. In this blog, we’ll explain how to stop SF₆ leakage using Belzona SF6-FIX — a fast, in-situ solution for sealing leaks in gas insulated switchgear. We will also cover what SF₆ is, why it’s used in gas circuit breakers and why it’s under regulatory pressure.

What is SF₆ (Sulphur Hexafluoride)?

SF₆ is a synthetic gas used primarily in the power industry as an insulating medium, for example in gas insulated switchgear and gas circuit breakers. Despite its usefulness, SF₆ has a global warming potential (GWP) over 23,500 times greater than CO₂, making it the most potent greenhouse gas (Intergovernmental Panel on Climate Change, fifth assessment report).

Why is SF₆ Used in Circuit Breakers?

SF₆ gas is widely used in electricity substations to insulate live components in medium- and high-voltage equipment. Its insulating and arc-quenching capabilities make it a key component in SF₆ gas circuit breakers, where it safely manages the switching of electrical currents.

SF₆ has a dielectric strength approximately three times greater than air, meaning it can withstand much higher voltages without breaking down, allowing electrical components to be placed closer together. As a result, gas insulated switchgear and circuit breakers filled with SF₆ can be made more compact, reducing the overall footprint of high-voltage installations. However, concerns around SF₆ leakage and its environmental impact have prompted increasing attention to switchgear maintenance and leak prevention.

SF₆ Regulations and F-Gas Compliance

The EU F-Gas Regulation (2024/573) restricts the use and emissions of fluorinated gases, including SF₆. Under these regulations SF₆ leakage prevention and repair is required, and the use of alternative technologies is encouraged. The US has similar regulations, and they exist worldwide, due to the global warming potential of SF₆, making compliance an operational necessity.

Belzona SF6-FIX can support power companies in meeting leak prevention goals, avoiding regulatory penalties, and maintaining ESG (environmental, social, and governance) standards.

How to Stop SF₆ Leakage: a Step-by-Step Guide Using Belzona SF6-FIX

To access the full application instructions for Belzona SF6-FIX and arrange for supply and application, please contact your local Belzona distributor.

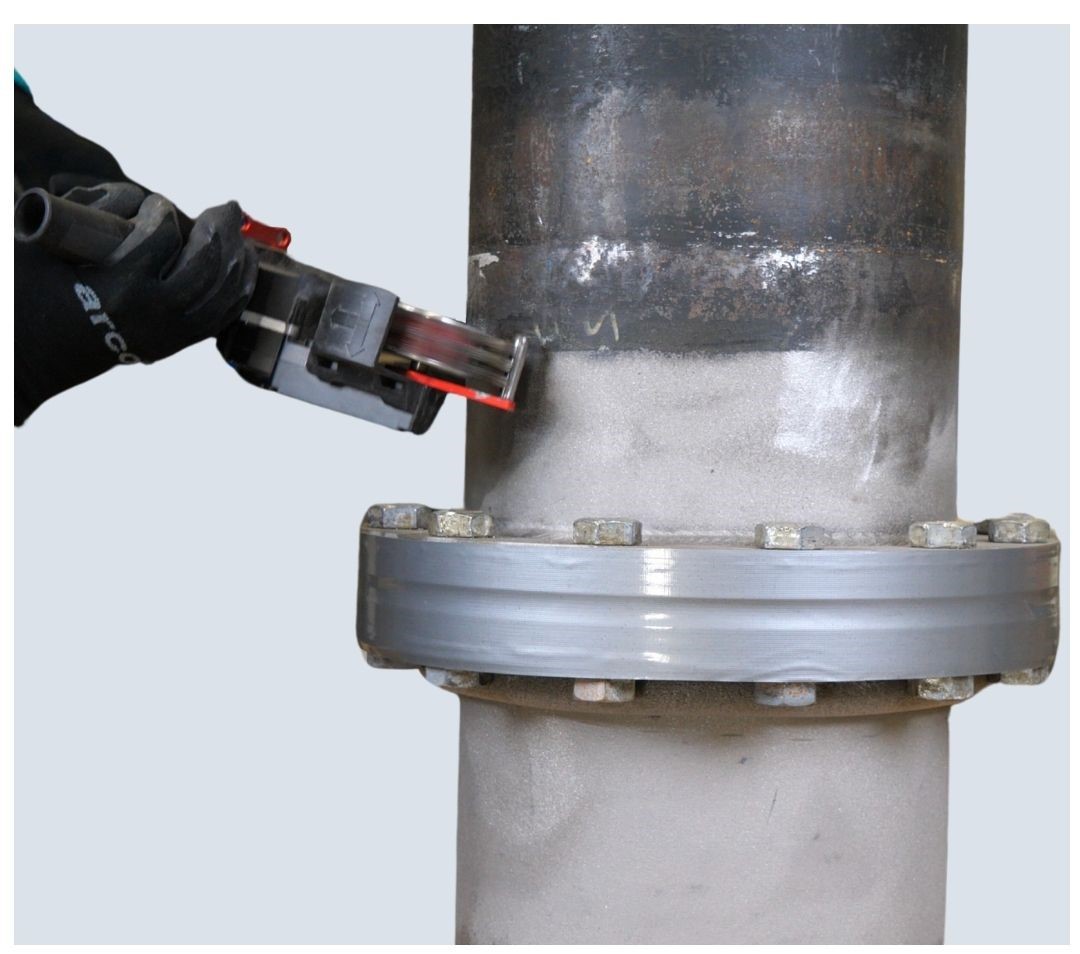

Step 1: Surface Preparation

First, ensure the area is degreased and mechanically roughened for optimal adhesion. The area should be prepared with a suitable power tool to achieve an SSPC-SP 11 bare metal power tool cleaned surface with a minimum profile of 25 µm (1 mil).

Step 2: Install Belzona’s Breather System

This allows gas movement during the cure phase and ensures internal pressure equalisation. This will then be capped off once the leaking flange repair is complete.

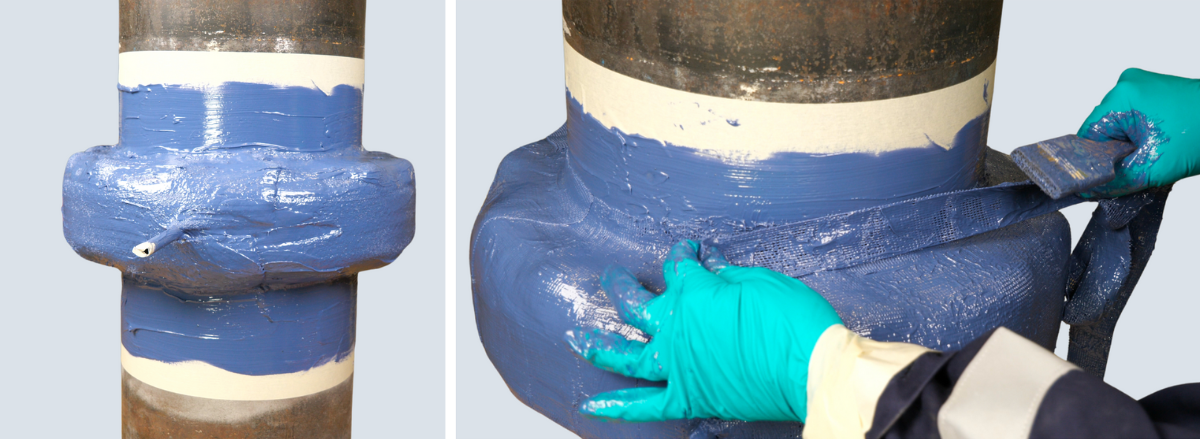

Step 3: Apply Belzona 7311 with Belzona 9341 Reinforcement Tape

Apply the first layer of Belzona 7311 to the breather system and prepared bond area using a brush. Once fully encapsulated, wet out and add the reinforcement tape.

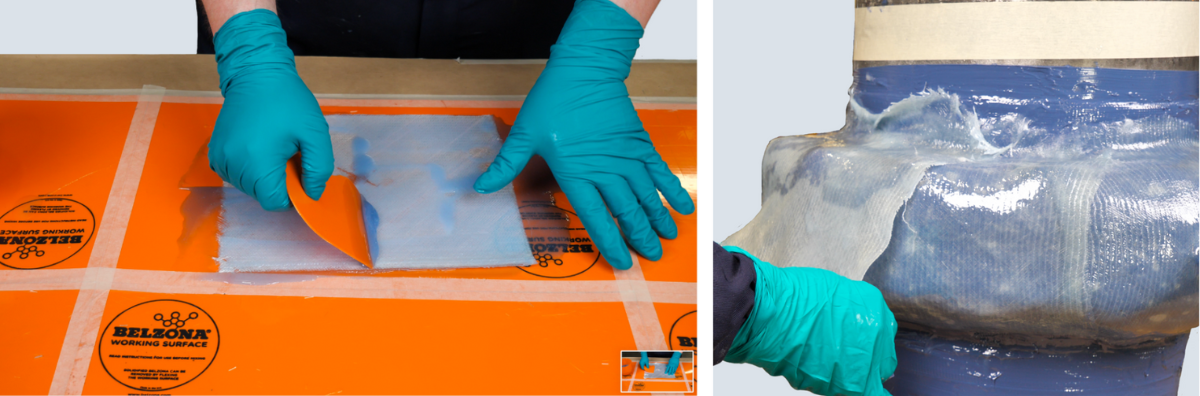

Step 4: Apply Belzona SuperWrap II with Belzona 9371 Reinforcement Sheet

This composite layer enhances pressure retention and creates a strong and durable wrap.

Step 5: Second Coat of Belzona 7311

An additional coat of Belzona 7311 ensures full encapsulation of the reinforcement system.

Step 6: Cap the Repair & Overcoat with Belzona 5721 (if required)

Cap off the breather system and add UV protection with Belzona 5721 if required.

Belzona SF6-FIX Stops SF₆ Leakage at UK National Grid Sites

Belzona SF6-FIX is utilised by British power company National Grid to rapidly and effectively seal SF₆ leaks, reducing emissions while keeping key grid infrastructure in service.

Rob Mills, Commercial and Portfolio Manager – SF₆ Emission Abatement at National Grid Electricity Transmission, said:

“Our collaborative work with Belzona, using its SF₆ leak seal technology, is helping us reduce SF₆ emissions while keeping our critical infrastructure in service. This means we can keep electricity flowing, while reducing the environmental impacts – a double benefit for consumers.”

Video: Belzona SF6-FIX

Frequently Asked Questions

What types of electrical equipment can benefit from SF₆ leakage repair?

SF6 breaker or Switchgear and circuit breaker maintenance is critical to ensuring safe, efficient, and environmentally compliant operations in the power industry — especially when sulphur hexafluoride (SF₆) is involved. Belzona SF6-FIX is suitable for use on a wide range of high-voltage equipment, including GIS (Gas-Insulated Switchgear), circuit breakers, disconnectors, and other pressurised SF₆ systems.

What are the benefits of using Belzona SF6-FIX for switchgear maintenance?

Belzona SF6-FIX is a solvent-free, cold-applied solution that safely seals SF₆ leaks, helping to reduce environmental impact and avoid costly gas loss. The durable repair system can typically be completed in a single day, minimising downtime. Applied by trained specialists, it ensures long-term performance without the need for hot work or equipment shutdown.

What regulations apply to Gas Insulated Switchgear (GIS)?

In regions like the EU, F-Gas Regulations require operators to monitor, report, and minimise SF₆ emissions, including the encouragement of alternative technology, such as the polymeric solutions offered by companies like Belzona. In many countries, non-compliance with these regulations can result in large fines.

Learn More

Contact Your Local Distributor to Learn More About How to Stop SF6 Leaks

Phil Robinson is an Association for Materials Protection and Performance (AMPP) Coating Inspector Program (CIP) Level 3 Inspector, with nearly 20 years of experience in executing major Belzona applications worldwide, both onshore and offshore. He currently holds the position of Applications and Training Director, based at Belzona’s Headquarters in Harrogate, UK. His expertise spans multiple industries, with a primary focus on the preservation of process equipment in the oil and gas sector.

In addition to his field experience, Phil plays a key role in the development of Belzona training programs, supporting Belzona’s global Distributor Network. He has also developed numerous application procedures and techniques to enhance the effectiveness of the product range. For example, in 2024, Phil was one of the key developers behind Belzona SF6-FIX, a sulphur hexafluoride (SF₆) leak solution that can be applied online, and without specialist tools.

With a passion for troubleshooting and implementing technical solutions, Phil excels at identifying and resolving complex challenges utilising protective coatings and repair composites.