Polyurethane and Epoxy Coatings and Repair Mortars Key Asset in Covid-19 Pandemic

Since the pandemic hit at the end of 2019, the pharmaceutical sector has experienced a staggering level of exponential growth. In order to meet the growing demands faced by this industry, engineers and maintenance teams worldwide are turning to polyurethane and epoxy composite repair systems and protective coatings to repair, protect and improve vital pharmaceutical equipment and assets.

Helping Pharmaceutical Companies Save Money and Combat Climate Change

Not only can these systems help pharmaceutical companies to save money by avoiding the need to decommission and replace assets, but they also help to support a greener future for the planet too.

Indeed, in light of the recent report from the Intergovernmental Panel on Climate Change (IPCC), it is clear that polymer technology plays a vital role in helping to reduce the predicted rates of global warming.

According to the report, which has been agreed by 195 countries, Earth is expected to hit the critical threshold of 1.5°C warming due to climate change within the next 20 years, regardless of how deeply global governments cut greenhouse gas emissions.

Ed Hawkins of the University of Reading, UK, an author on the IPCC report said:

‘Every bit of warming matters. The consequences get worse and worse and worse as we get warmer and warmer and warmer. Every tonne of CO2 matters.’

While it is incredibly sobering to see such figures, as Hawkins says ‘Every tonne of CO2 matters.’ As such, Belzona systems have an important part to play in the reduction of CO2 emissions for pharmaceutical companies, as well many other business and industry areas.

Unprecedented Growth in Pharmaceutical Industry

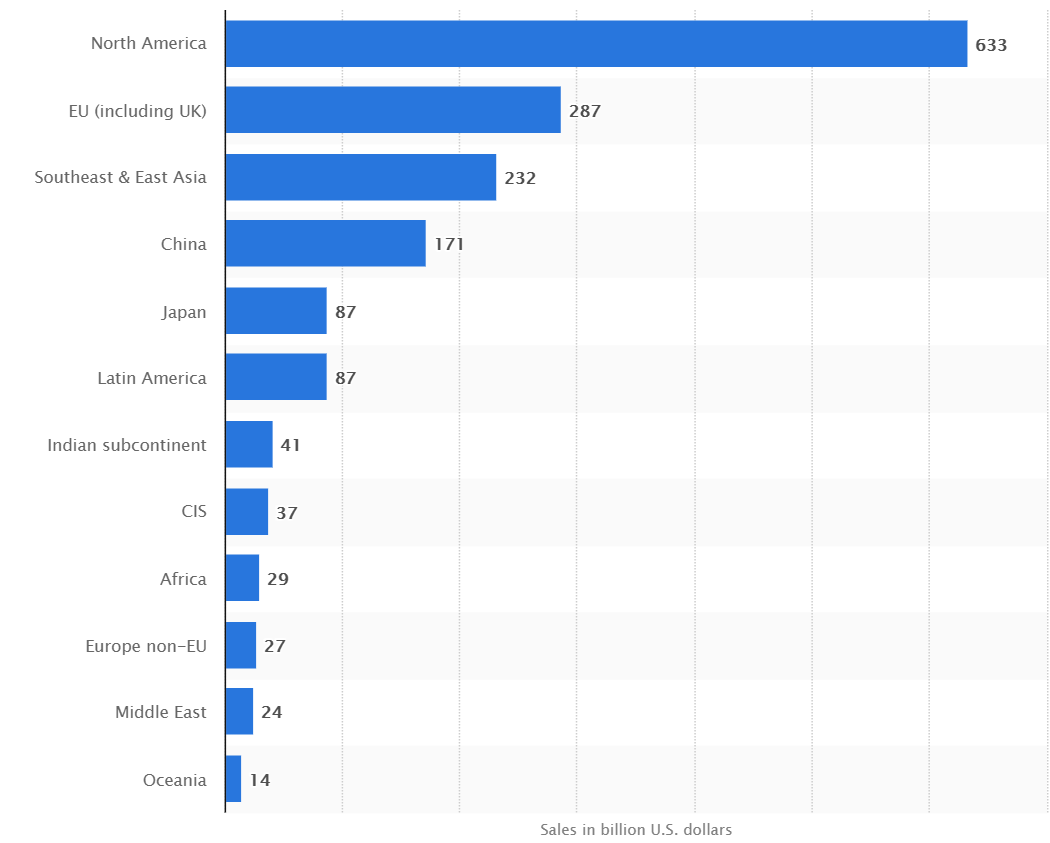

Outlining the growth of the pharmaceuticals market, figures provided from global statistics company, Statista, say:

‘As of end-2020, the total global pharmaceutical market was valued at about 1.27 trillion U.S. dollars. This is a significant increase from 2001 when the market was valued at just 390 billion U.S. dollars.’

The statistics go on to identify how, globally, the United States has emerged as the leading market for pharmaceuticals, followed by a group of emerging markets. These include Brazil, India, Russia, Colombia and Egypt, amongst others. It is these emerging markets that have shown the fastest increase in pharmaceutical sales.

In terms of future growth, according to a report by Absolute Markets Insights, the pharmaceuticals market is expected to be valued at 1809.09Bn US$ by 2022. This figure is staggering when compared with its valuation in 2017 of 1350.29Bn US$.

By 2024, at the top of the table for projected pharmaceutical sales is North America, with an estimated 633Bn US$. Second is Europe (including UK), with an estimated 287Bn US$ and third is Southeast and East Asia with 232Bn US$.

China is also predicted to have significant growth in 2024, with sales of 171Bn US$ projected. Also in this year, Africa is predicted to have sales of 29Bn US$.

From these statistics, it is clear to see how not only has the pharmaceuticals industry experienced unprecedented growth since the genesis of the global pandemic, but its future trajectory is also expected to show further significant growth.

Fighting Erosion, Corrosion and Chemical Attack in Pharmaceutical Sector

Due to the increased demand in this industry, it is absolutely critical that investments are made into ensuring key pharmaceutical assets are not just maintained, but also actively improved for the long term in order to support this future growth.

In addition, considering the fundamental role the pharmaceutical industry plays in the fight against Covid-19, it is essential that these solutions can be carried out whilst incurring as minimal downtime as possible.

Belzona’s polymeric solutions, which have been honed over the course of nearly 70 years, are specially developed to combat the effects of erosion, corrosion, abrasion and chemical attack in a variety of application environments within the pharmaceuticals sector.

These polyurethane and epoxy repair materials and mortars play a critical role in keeping machinery, equipment, buildings and structures in the pharmaceutical sector functioning at their optimum level. Furthermore, thanks to the fast-curing properties of Belzona technology, they help to keep downtime to an absolute minimal.

Considering the fundamental role the pharmaceutical industry plays in the fight against Covid-19, these repair, rebuilding and coating systems are incredibly valuable assets to the sector.

Comprehensive Range of Polyurethane and Epoxy Repair and Protection Systems

Belzona offers a range of solutions for a variety of different application areas in the pharmaceutical sector. Amongst others, these include: pumps, chemical containment areas, mechanical repairs, floor coatings, grip systems, concrete sealing, tanks, vessels, pipes and exchangers.

The following three case studies detail how Belzona polymeric repair composites and industrial protective coatings have been used to:

1. Repair waste and drain channels damaged by aggressive chemicals

2. Protect a settlement tank against erosion and corrosion

3. Install a safety grip system for an exterior flooring area

Waste and Drain Channels Protected Against Aggressive Chemicals

At a pharmaceutical company in Finland, the Client required a repair solution for two chemical containment areas in the process basement and distillery.

Due to years of use, the flooring around the drain-channels in the process basement had become deteriorated and uneven. As a result of this, chemical waste (including organic and inorganic acids, alcohols, alkalis, halocarbons) had begun to pool in certain areas, rather than running down the drain channel for transportation to the waste treatment area. A solution was needed that would provide optimum chemical protection whilst facilitating the seamless transportation of the waste.

In the distillery area, after being subjected to years of chemical attack, a chemical-resistant screed was required to repair the cracked weld seams in the waste-channel. The Client requested a comprehensive repair to this area, whereby both the bottom as well as the sides of the waste-channel would be treated.

Belzona Specification

To repair and protect the damaged areas, Belzona 4181 (AHR Magma-Quartz) was specified. This is a 3-part epoxy repair composite designed for the repair, resurfacing and protection of concrete and stone subject to heat and chemical attack. As this material provides outstanding chemical resistance and is suitable for application on both horizontal and vertical surfaces, it was the perfect solution to treat both of the damaged areas.

Application Method

Firstly, all loose, crumbling and deteriorated concrete was cleared away. Next, the substrate was thoroughly scrubbed with a detergent wash and rinsed with clean water. Once the substrate was dry, Belzona 4911 (Magma TX Conditioner) was then applied by brush to condition the area. Following this, Belzona 4181 was applied using a metal straight edge to achieve a uniform thickness prior to smoothing off using a steel float. The application areas were then left to cure. Belzona 4181 reaches full chemical resistance after five days at 77°F/25°C and after 10 days at 59°F/15°C.

Polymeric Systems Extend Lifespan of Pharmaceutical Assets

As the factory was scheduled to be taken out of production after two years, it was imperative that the chemical-resistant coating would remain effective up until this point. Due to the outstanding chemical-resistant properties of Belzona 4181, the Customer has the complete assurance that the repair area will remain intact for the required amount of time. Indeed, Belzona 4181 has been proven to provide years of protection against aggressive chemicals way beyond the specified two-year point.

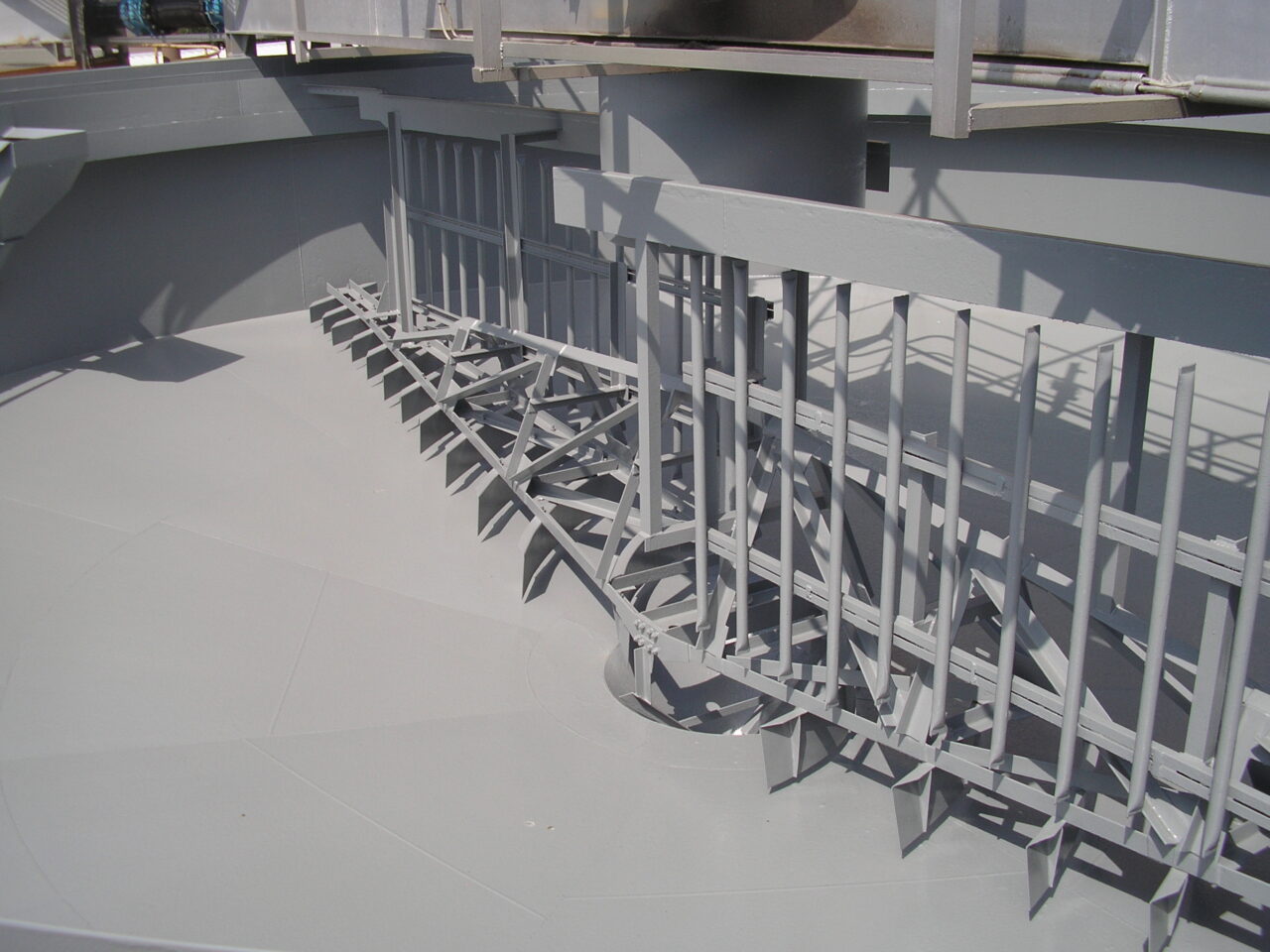

Belzona Protects Settlement Tank Against Erosion and Corrosion

At a pharmaceutical company in Slovakia, the tank basin and mixing equipment were suffering from severe corrosion damage. As a result, the tank was failing to perform at its optimum efficiency, which in turn was resulting in profit loss for the Client. A solution was required that would protect the equipment against the effects of erosion and corrosion whilst incurring minimum downtime in the application process.

Belzona Specification

To combat the deep-set corrosion damage, Belzona 5811 (Immersion Grade) was specified. This system protects equipment operating under immersion in aqueous solutions up to 50°C (122°F) from the effects of corrosion. As this epoxy coating provides outstanding corrosion resistance, it was the perfect solution to repair and protect the settlement tank for the long term.

Application Method

Firstly, all residue from the area was cleared away and the substrate was cleaned using Belzona 9111 to ensure that it was clear of any contamination. The area was then grit blasted using an angular abrasive to Swedish Standard Sa2 ½ (near white metal finish) with a minimum 3 mil (75µ profile).

Belzona 5811 was then spray applied using heated airless equipment to a thickness of 250µ. This was followed by a second coat of 5811 at a further thickness of 250µ. This application was then left to cure. For full mechanical/thermal loading or water immersion, Belzona 5811 cures in 2 days at 86°F/30°, 5 days at 68°C/20°C and 8 days at 50°F/10°C.

Spray Application Method Kept Downtime to an Absolute Minimum

Belzona provided an effective solution to not only repair the basin and mixing apparatus, but also to protect these assets for the long term, thus extending the lifetime of the equipment. By using the spray-application method, this facilitated a fast application with minimum downtime being incurred. In turn, this allowed the Company to save money down the line as it mitigated any potential profit loss that could have been incurred through extensive periods of downtime.

Grip System Keeps Pharmaceutical Plant Operating Safely

The exterior flooring at a Pharmaceutical plant in Switzerland was exhibiting signs of deterioration. This was causing the forklift trucks to slip when loading and unloading.

This was a threat both in terms of health and safety, as well as the potential profit loss that would ensue should employees require time off work or indeed if assets became damaged in the loading process. As such, the Client required a safety grip system that would ensure the loading operations in the pharmaceutical plant would run as smoothly and safely as possible.

Belzona Specification

In order to repair and rebuild the damaged concrete, Belzona 4111 (Magma Quartz) was specified. Formulated to provide high mechanical and impact strength, this 3-part epoxy repair composite is the perfect solution to rebuild the damaged areas.

In order to further fortify the flooring area with excellent abrasion resistance, the epoxy coating, Belzona 5231 (SG Laminate), was specified.

To provide the safety grip system, the 2-part epoxy coating, Belzona 1821 (Fluid Metal) combined with the durable aggregate, Belzona 9211 (Supergrip Aggregate) were chosen. The combination of these systems is specially designed to create positive drive and reduce slippage. To consolidate the repair, Belzona 5233 was specified. This is a solvent-free, UV-stable floor coating designed to provide long-term protection and durability for internal and external flooring applications.

Application Method

Firstly, any debris was cleared away and the substrate was thoroughly cleaned. The surface was then conditioned with Belzona 4911 (Magma TX Conditioner) using a stiff bristled brush. Using a trowel, the epoxy repair mortar, Belzona 4111, was then applied to rebuild the damaged areas.

Once cured, the epoxy coating, Belzona 5231 was applied to the substrate using a nap roller. The coating was pushed well into the surface, ensuring the substrate was completely wetted. Once the first coat had cured, a second coat of Belzona 5231 was then coated onto the area.

Following this, the Belzona grip system was applied. Masking tape was used to mark out the alternative stripes in the grip pattern. Next, Belzona 1821 was applied directly onto the prepared surface using the plastic applicator to the film thickness of 375-500µ.

Belzona 9211 was then sprinkled onto the uncured Belzona 1821 coating to the required density. A wooden block was used to press the aggregate into the Belzona 1821. A brush was then used to sweep over the system and remove any excess Belzona 9211. The masking tape was then immediately removed to give a neat feather-edge to the application.

After the grip system had cured, the UV-stable coating, Belzona 5233, was applied at a thickness of 125µ.

Grip System Keeps Pharmaceutical Site Running Smoothly and Safely

Having deployed Belzona systems in the past, the Client had complete confidence in the Belzona technology. As such, Belzona was the obvious choice for providing the safety grip system to the external area.

The grip system ensures that the forklift trucks can safely unload and offload their goods, without fear of slipping. This helps to keep operations at the pharmaceutical site running as efficiently and safely as possible.

Belzona Systems Help Businesses Cut Carbon Emissions in Line with Paris Agreement

As demonstrated in these three case studies, Belzona’s range of polymeric repair and protection systems can improve key pharmaceutical assets for the long term, whilst avoiding the need for extensive periods of downtime.

By breathing new life into key assets instead of decommissioning or replacing them, this helps businesses to not only save money, but also to reduce their carbon footprint too. By deploying Belzona systems in this way, businesses can make significant gains in achieving the net zero carbon emissions target by 2050, as set out in The Paris Agreement.

To view Belzona’s full range of solutions for the pharmaceutical industry, please click here.

Interested in purchasing Belzona’s epoxy-based composites?

Chloe Hirst is the Senior Copywriter at Belzona Limited and is based in Harrogate, England. She gained a Bachelor’s Degree (with Hons.) in Media and Communications (specialising in Journalism) at Goldsmiths College, University of London. Chloe regularly writes case studies and thought leadership content featuring a variety of different industries, with a special focus on the renewables sector. In both 2023 and 2024, she won the Best Manufacturing Content Creation Specialist (UK) Award as part of Acquisition International’s Influential Businesswoman Awards.