This blog post provides step-by-step guidance on how to repair a worn shaft using a former and the epoxy paste, Belzona 1111 (Super Metal).

Shafts often operate in immersed or semi-immersed conditions, making them vulnerable to corrosion, chemical attack, vibration, friction, and abrasive media. Left unaddressed, worn shafts can shut down entire machines, halting production and causing significant revenue loss.

Belzona Solution:

- Belzona 1111 (Super Metal): This 100% solids cold-applied epoxy repair solution will not corrode and resists a wide range of chemicals, making it the perfect solution for the shaft repair. It is easy to mix and apply without the need of specialist tools and can be machined using conventional tools.

Shaft Repair with a Forming Technique: A Step-By-Step Guide

- Clean the Worn Shaft

Thoroughly clean the area to remove all the grease, dirt and other surface contaminants.

- Undercut the Shaft

One grinder fitted with a suitable disk to undercut the shaft by 1/16″ (1.5 mm) around the circumference.

- Degrease the Worn Shaft

Clean the prepared area with Belzona 9111 (Cleaner/Degreaser) to remove all surface contaminants.

- Apply Release Agent

Apply Belzona 9411 (Release Agent) to the internal surface of the former.

- Apply Release Agent to the Damaged Shaft

Apply Belzona 9411 (Release Agent) to the area surrounding the repair area.

- Mix Belzona 1111 (Super Metal)

Thoroughly mix Belzona 1111 (Super Metal) 2-part epoxy paste for metal repair until a uniform color, free of any streakiness, is achieved.

- Wet Out Former

Apply a thin layer of the mixed Belzona 1111 (Super Metal) on the internal surface of the former.

- Firmly Apply Shaft Repair System

Apply a thin layer of the mixed material onto the shaft, pressing down firmly into the roughened profile.

- Form a Peak

Form a peak towards the center of the application area.

- Position Shaft Former

Position the former around the shaft.

- Clamp Shaft Former

Secure the former in position with fasteners ensuring that the excess material is extruded from the ends of the former.

- Remove Excess

Remove excess material and allow the applied material to cure.

- Remove Former

Once cured, carefully remove the bolts and the former.

- Smooth Down

Smooth out the surface of the application area with an emery cloth.

Frequently Asked Questions

What are the advantages of using Belzona cold-curing epoxy composites for shaft repair as an alternative to welding?

Belzona’s cold-curing epoxy composites offer several advantages over welding:

Cost effectiveness: With less specialised labour, fewer safety precautions needed, and reduced downtime, the overall cost of the epoxy shaft repair method is much lower than welding.

Reduced downtime: Worn Shaft repairs can be performed in situ, avoiding the lengthy process of removing, transporting, and reinstalling heavy or complex machinery.

No thermal distortion or metallurgical change: Since there’s no high heat involved, there is far less risk of warping, cracking, or altering base‐metal properties.

Lower safety risk: Fewer hot-work hazards—no open flames, reduced risk of burns or fires, and lower exposure to weld fumes—translates into safer working conditions.

Why is repairing worn shafts so critical in rotating equipment maintenance programs?

Repairing worn shafts is essential for several reasons:

Proven durability: Case studies of Belzona repairs show that, once properly applied, cold-curing shaft repairs can last for many years under real operating conditions.

Maintaining performance and efficiency: Shaft wear leads to misalignment, increased friction, vibration and power losses. If left unchecked, these degrade efficiency.

Preventing cascade failures: Worn shafts stress other components—bearings, seals, couplings—and these parts often fail prematurely when shaft wear is not addressed.

Minimising unplanned downtime: Proactive repair avoids unexpected breakdowns, which are usually far more disruptive and expensive than planned maintenance.

Extending component and machine life: Restoring shafts to correct dimensions helps the machine run as designed, which improves longevity and mitigates shaft replacement.

What are the common causes of shaft wear, and how can wear be prevented?

Causes of wear:

- Mechanical abrasion (solid particles, seals, bearings)

- Corrosion (chemical attack, moisture, process fluids)

- Misalignment and vibration leading to fretting or uneven load distribution

- Poor or inadequate lubrication (or lubricant contamination)

- Material selection not suited to the operating environment (e.g. insufficient hardness or corrosion resistance)

Prevention strategies:

- Design equipment for maintainability (accessibility, ease of inspection)

- Use epoxy repair materials that resist corrosion and abrasion such as Belzona 1111 (Super Metal)

- Ensure precise alignment during installation, and periodic alignment checks

- Maintain lubrication regimes, using correct lubricant and cleanliness

- Monitor vibration, bearing temperatures and wear patterns to detect early onset of wear

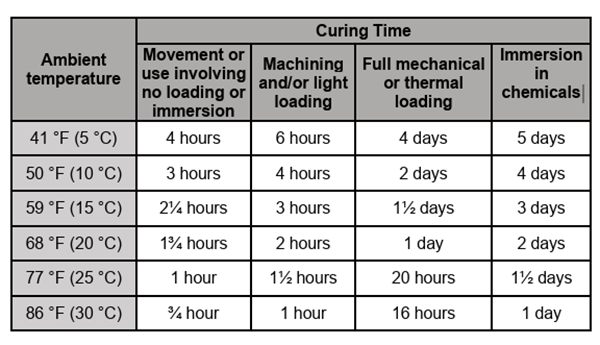

How long does Belzona’s shaft repair system, Belzona 1111 (Super Metal), take to cure?

Belzona 1111 (Super Metal) should be allowed to ambient cure as follows. Bear in mind that these curing times are for a repair thickness of approximately 6mm (0.25 inches). They will be reduced for thicker sections and extended for thinner sections.

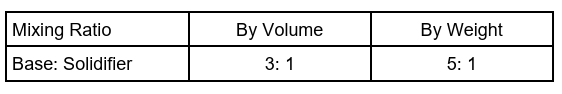

What is the mixing ratio of the shaft repair epoxy, Belzona 1111 (Super Metal)?

For mixing small quantities of the shaft repair epoxy, Belzona 1111 (Super Metal), use:

What are the different types of shafts that Belzona 1111 (Super Metal) be applied to?

Belzona 1111 (Super Metal) can be used on pump shaft repairs, motor shaft repairs, gearbox shaft repairs, amongst others.

Learn More

How to Repair a Worn Shaft Using Injection

How to Rebuild an Oversized Keyway

How to Repair Metal Loss on Pipework (With GIFs and Video)

Video: How to Repair a Worn Shaft

Contact Your Local Distributor to Learn More About How to Repair a Worn Shaft

Yulia Burova, Marketing Director, Belzona Inc., Miami FL, USA

In-situ repair solutions are cheaper, innovative, and efficient. Well done!

Dear Mr. Fernando,

Yes I believe its possible to rebuild and then machine down to size, in a way thats what they have been designed for. We recommend that you contact a local Belzona Distributor for them to assess the conditions of the repair area and make the right recommendation of the solution. You can find a Belzona Distributor in your area by using this link: https://www.belzona.com/en/about/disfinder.aspx or let us know where you are located and we will send you contact information.

Is it possible to repair ductile cast iron SG EN-GJS-400-15? We have to repair bore of butterfly valve stem. Butterfly valve body material of the valve body is ductile cast iron SG EN-GJS-400-15. After repairing the bore it should machined to get the required bore size. Is it possible to machine the repaired surface with Belzona?

Dear Mr. Fernando, thank you for contacting us! One of our engineers will get back to you shortly.

Best regards,

Belzona

Hello, I have an issue where the Bearing froze on a basket shaft for a washing machine. The part is not longer available. The inner race wore the shaft down approximately .035″ radially. The bearing fit is too loose to put the machine back into service. Since there will be a load in the area of repair, do you think that your product will withstand the pressures exerted in this particular area where the bearing sits? Thanks and much appreciated.

Randy,

Thank you for your question! We have passed on your inquiry to our Technical Department. Best regards, Belzona

howdy from El Paso Tx. We have a Minster 60-ton metal stamping press. On the crankshaft in the area of the flywheel there is 2 roller bearings that has been metal sprayed and is failing. we need to repair that to bearing fitment 3.937″. there isn’t any real abuse happening there, it just needs a good true fit. re; minster cfc 22 clutch

Hello Mr. Stan,

Thank you for your question!

We recommend that you contact a local Belzona representative for your area. Here is the company’s contact information:

Danco Technologies, Inc.

PO Box 6576

Abilene, TX, 79608, United States

Telephone:325-793-9200

Fax:325-793-2022

Please feel free to let us know if you have any other questions at all.

Best regards,

Belzona Team

Dear Yulia Burova,

We want to use Belzona product to repair a worn shaft of wind generator, do you have any case off successful application for wind industry?

Thanks!

Hello Alexandre,

Thank you for your question. We have completed multiple wind turbine shaft repairs. Here are some examples:

https://khia.belzona.com/en/view.aspx?id=7502

https://khia.belzona.com/en/view.aspx?id=7536

https://khia.belzona.com/en/view.aspx?id=6437

Could you please let us know the location of the wind turbine and we’ll put you in touch with your local Belzona representative.

After repairs can these shafts in the case of a mature run at 5000rpm

hi. I have shaft with 2 inches diameter. Material is 410 AISI and 1400 rpm can I use this type of your product? Please help me?

Dear Rashel,

Thank you for the question and reading our blog!

We have a few case studies that you can review as they feature the repair you are interested in:

https://khia.belzona.com/en/view.aspx?id=7835

https://khia.belzona.com/en/view.aspx?id=1235

https://khia.belzona.com/en/view.aspx?id=5484

If you follow the procedure outlined in this post as well as Belzona’s Instructions for Use for Belzona 1111.

Please feel free to let us know if any further questions.

Best regards,

Belzona Team

Hi,

I have a worn out chrome zirconium copper shaft which has got worn out,the area which has worn out is subjected to high current transmission of 12000a and heat,similar to a carbon contact brush,the only difference here being the stationary shoe is silver pad.

Please let us know if belzona has a solution/product for this repair

Dear Sathya Narayan,

Thank you for your inquiry!

We will need to have more details of the operating conditions to give you an answer. Please fill out this form so one of the Belzona representatives in your area can contact you to assist you with the inquiry: http://www.belzona.com/en/contact.aspx.

Best regards,

Belzona Team

Pingback: Shaft Repair Using Injection with Belzona 1321 and a 3D Former

how can we fix only a zip cut mark on a shaft when remouving a coupling or a trouche nic when flame cutting the coupling hub?

Any sugestions?

Dear Mr. Brazeau,

Thank you for your question.

Belzona has many applications that are repeated on a regular basis. We make these applications in to application system leaflets and they show clients how to complete the work step by step. From your question I think the application system leaflet MPT-03 Repairing a scored shaft / hydraulic ram would be a good starting point.

Please share with us where you are located or fill out this form http://www.belzona.com/en/contact.aspx so our local office could provide this information to you and any further assistance you may need.

Belzona Team