INTRODUCTION TO BELZONA’S UTILIZATION OF 3D TECHNOLOGY

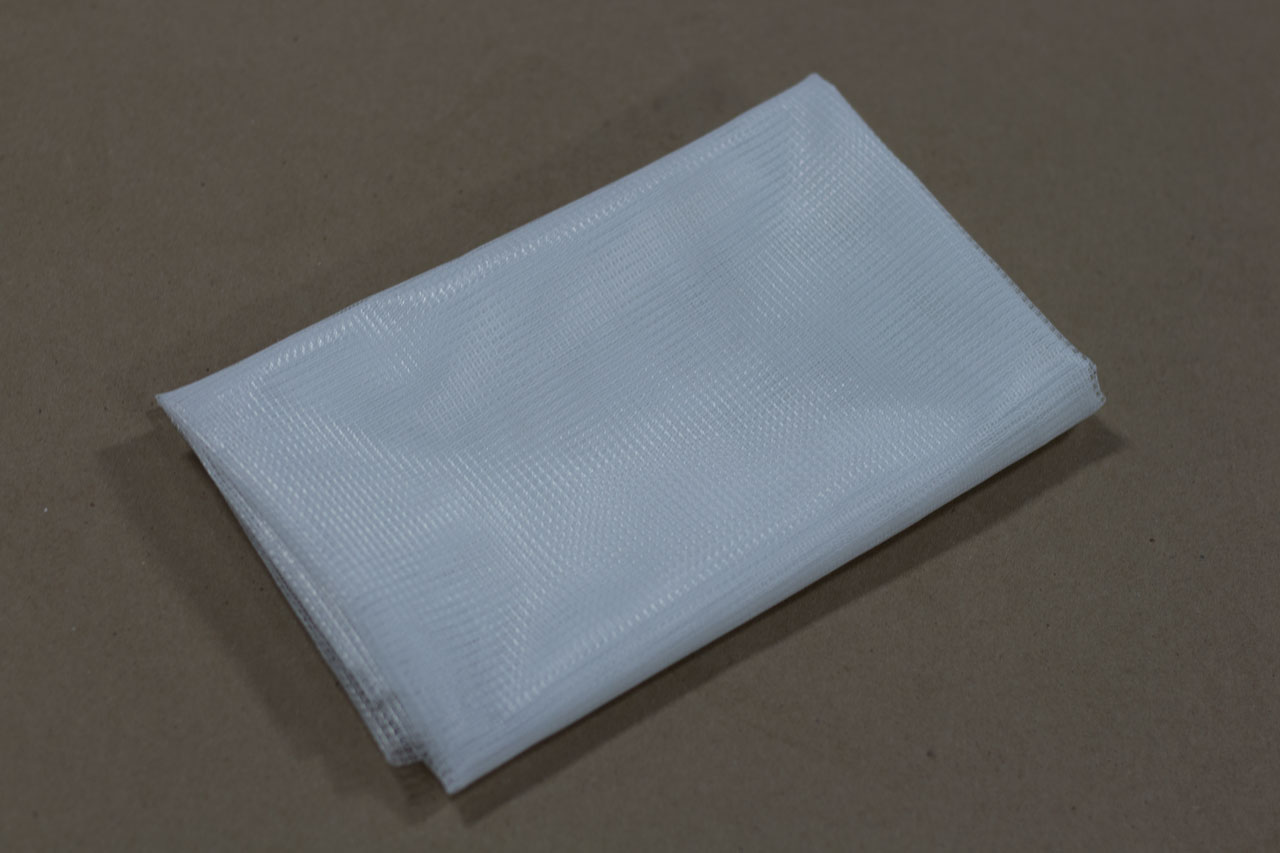

With the use of the latest 3D printing technology, Belzona has developed a Belzona 3D mesh to assist with live leak repairs on straight pipes. This 3D mesh is currently available in North and South American regions and is made from high strength flexible nylon. The flexibility of the mesh allows it to contour pipes of any diameter that is ≥ 3″ (7.62 cm). This eliminates the need to fabricate a metal plate to match the specification of a pipe each time an emergency arises.

Designed to be used with Belzona 1100 and 1200 series, the repair with Belzona 3D mesh is safe, easy to carry out and does not require hot work or specialist tools. The repair can be done in situ without the need to disassemble equipment or remove from service. Belzona repair composites allow for reinforcement of the structural integrity of the pipe and keep it in service for years to come. The Belzona 3D mesh live leak repair not only stops a leak in a timely manner, but also offers corrosion resistance and extends the service life of equipment.

BELZONA HOW-TO

In this blog post we demonstrate how Belzona 3D mesh combined with Belzona repair composites perform a live pipe leak repair in a matter of couple of hours. This repair makes it an excellent alternative to other traditional methods of stopping pipe leaks.

BELZONA 3D MESH DRAWING

VIDEO: HOW TO STOP A PIPE LIVE LEAK WITH BELZONA 3D MESH

To carry out a live pipe leak repair and to reinforce the structural integrity of the pipe, we used Belzona 1212, Belzona 3D Mesh and a few tools from our machine shop. First, we prepared the surface by removing the old paint and roughening it with a file. The entire repair area was then degreased with Belzona 9111 (Cleaner/Degreaser). We measured a suitable length of the reinforcement sheet and cut a hole in the middle to match the opening in the mesh. Next, the entire contents of Belzona 1212 Base and Solidifier were transferred onto a Belzona mixing board. The components were thoroughly mixed until a uniform color was achieved and the material no longer showed any streakiness. Following the mixing, a layer of mixed Belzona 1212 was applied to the Belzona 3D mesh and to the clean repair area on the pipe. The Belzona 3D mesh with the reinforcement sheet was then positioned on the pipe and aligned with the leak. The pipe was wrapped with the reinforcement sheet to secure the Belzona 3D mesh. We smoothed out the surface using the remaining product. Once cured, the plug was inserted and tightened with an Allen key.

SUPPLIES AND TOOLS NEEDED FOR THIS REPAIR

STEP-BY-STEP INSTRUCTIONS OF A LIVE LEAK REPAIR WITH BELZONA 3D MESH

Interested in purchasing Belzona’s repair composites and protective coatings?

Yulia Burova, Marketing Director, Belzona Inc., Miami FL, USA