Can solutions which have a perceived higher upfront cost in product ultimately prove to be more economical? Cheap repair systems may work as a ‘quick fix’ solution and temporarily provide respite to the problem. However, frequently these products are simply not of the same quality and therefore cannot last the length of time.

Additionally, expenses associated with a quick fix (such as incurred downtime, OPEX, logistics, access and approvals to name a few) can exponentially increase this perceived cost. As a result, when it comes to searching for a perfect maintenance solution, Operators look at the whole supply and apply cost, accounting for any downtime and loss of production as well as the total future operating and maintenance costs.

Operators and Asset Owners who choose to invest in Belzona can expect a fast application, longevity and better performance. Rather than assets needing frequent replacements, they can continue to perform with minimal remedial work. Here are two occasions when the Belzona Investment ended up saving customers money in the long run.

BELZONA INVESTMENT: COLD PLATE BONDING ON A DECK REPAIR

Benefit – Lack of downtime

Location – Gulf of Mexico

Potential Loss Prevented – est. $3 million

For years, a production platform deck did not receive adequate maintenance and consequently the metal began to experience severe corrosion. A repair was needed quickly as the structural integrity was at risk and as a result, so were safety personnel.

Options

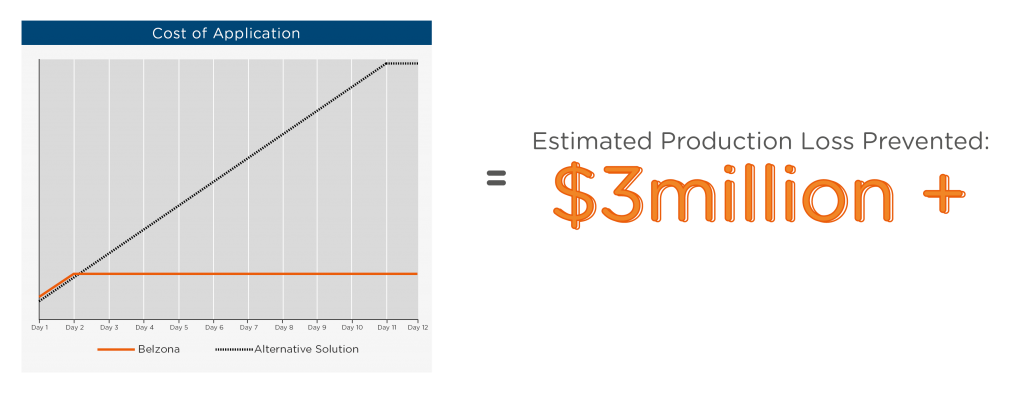

The first option was to weld plates to the deck, a process predicted to be 20% cheaper than Belzona’s cold plate bonding system. However, the downtime required for the welding was expected to take between 10-12 days, with an estimated daily cost of $350,000 in lost production.

Whereas, the Belzona specified solution: Belzona 1121 (Super XL-Metal), used to cold bond the plates to the surface, and Belzona 5811 (Immersion Grade) with an aggregate, used to create a grip system to coat this, only required one day of downtime.

Belzona 1121 was chosen as a solvent-free solution for repairing and resurfacing metal which will not corrode, averting the original issue.

Belzona 5811 was chosen because it provides excellent protection from environmental damage such as salt water.

Although the Belzona investment seemed greater upfront considering the amount of materials and labour costs involved, in the long run, it turned out to be a more cost-efficient solution as it did not incur any loss in production.

BELZONA INVESTMENT: COLD PLATE BONDING ON A DECK REPAIR

Benefit– Less maintenance/longevity of Belzona solutions

Location – UK

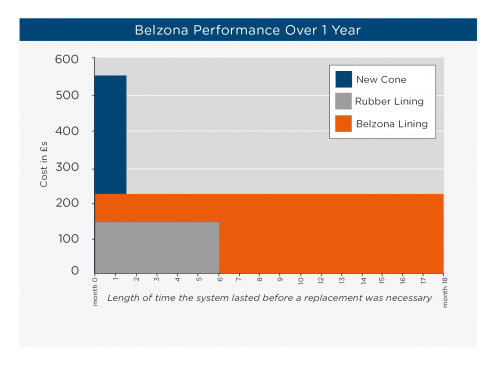

Money saved – After 10 years, in material alone per cone the Belzona system saved the customer over £50,000 versus an uncoated cone and over £2,500 versus a rubber-coated cone. This does not include the price of not having to halt operation every few months to replace cones or coatings. There are usually 4-6 cones in operation at any given time.

At a lime stone quarry, the steel nozzles used on cyclone wash plant filtration were suffering from severe abrasion damage. Consequently, they were only lasting around six weeks in service before needing to be replaced (£500-600 for a new nozzle). This also resulted in the plant work continually halting as the old nozzles were removed and the new fitted.

As this was happening far too frequently, the quarry began to look for linings which could slow down the abrasion damage. At first a rubber lining was chosen, which cost £150 but only lasted for six months. Then, Belzona 1812 (Ceramic Carbide FP) was specified by Belzona at a higher upfront cost of £200 per nozzle. This material is designed to resist fine-particle abrasion damage and incorporates abrasion-resistant ceramic aggregates.

This material went on to last for 18 months before needing maintenance. This meant that the quarry did not have to keep spending money on the upkeep of the nozzles and that they also avoided expensive downtime.

The Belzona Investment impressed the quarry so much that it is now the standard for coating nozzles and they are looking at using different Belzona products for the wash plant.

These are just two examples of the “Belzona Investment” where Belzona justified its initial investment by providing a superior solution. Whether that is in terms of providing a fast-curing solution, which avoids lengthy downtime; improving the performance of an asset; or because of its superior quality, which lasts longer and does not need replacing.