This blog post provides step-by-step guidance on how to repair and protect ship bilges using the 2-part epoxy paste, Belzona 1111 (Super Metal), along with the anti-corrosion coating, Belzona 5811 (Immersion Grade).

Ship bilges are prone to oil, water and debris accumulation, accelerating corrosion and potential hull integrity issues. Utilising Belzona’s polymeric repair and protection systems mitigates the need for expensive and time-consuming alternative repair methods, while fortifying the bilge with corrosion-resistance for the long term.

Belzona Solutions:

- Belzona 1111 (Super Metal): A composite repair system for rebuilding corroded metal surfaces.

- Belzona 5811 (Immersion Grade): A high-performance epoxy coating that provides industrial-grade corrosion protection.

How to Repair and Protect Ship Bilges: A Complete Guide

Step 1: Surface Preparation Prior to Application of Belzona 1111 (Super Metal)

The first step prior to the application of the composite repair system, Belzona 1111 (Super Metal), is surface preparation. Grit blast the substrate to the requirements of SSPC SP 10 or ISO 8501- SA 2 ½ cleanliness, with a minimum average 75 µm (3 mils) profile. Use tape to mask the repair area and prevent excess product on the structure.

Step 2: Mixing Belzona 1111 (Super Metal)

Belzona 1111 (Super Metal) has a mixing ratio of 3:1 parts base to solidifier, by volume, and 5:1 parts base to solidifier, by weight. Transfer the entire contents of the base and solidifier modules onto a Belzona working board. Mix the components together using a Belzona spatula in a figure-of-eight motion.

Step 3: Application of Belzona 1111 (Super Metal)

Apply Belzona 1111 (Super Metal) to the substrate using a Belzona spatula or short-bristled brush. Press the epoxy repair paste down firmly to fill all cracks, remove entrapped air and ensure maximum contact with the surface. Frost-blast the surface prior to overcoating with Belzona 5811 (Immersion Grade).

Step 4: Mix and Apply Belzona 5811 (Immersion Grade)

The 2-part epoxy coating, Belzona 5811 (Immersion Grade), has a mixing ratio of 3:1 parts base to solidifier, by volume, and 5:1 parts base to solidifier, by weight. Transfer the entire contents of the solidifier container into the base container. Mix thoroughly together to achieve a uniform material free of any streakiness. Using a short-bristled brush or rubber squeegee, apply Belzona 5811 (Immersion Grade) to the substrate to a thickness of 250 µm (10 mil).

Step 5: Mix and Apply Second Coat of Belzona 5811 (Immersion Grade)

Once the first coat of Belzona 5811 (Immersion Grade) is firm (this can take 5-7 hours at 20°C (68°F) and 8-10 hours at 10°C (50°F)), mix and apply the second coat of Belzona 5811 (Immersion Grade) using the same method outlined above. The system should be allowed to ambient cure as follows:

| Ambient Temperature | For Light Loading | For Mechanical and/or Thermal Loading or Water Contact | For Chemical Contact |

| 10°C (50°F) | 36 hours | 8 days | 12 days |

| 20°C (68°F) | 18 hours | 5 days | 7 days |

| 30°C (86°F) | 9 hours | 2 days | 5 days |

| 40°C (104°F) | 5 hours | 1 day | 2 days |

Frequently Asked Questions

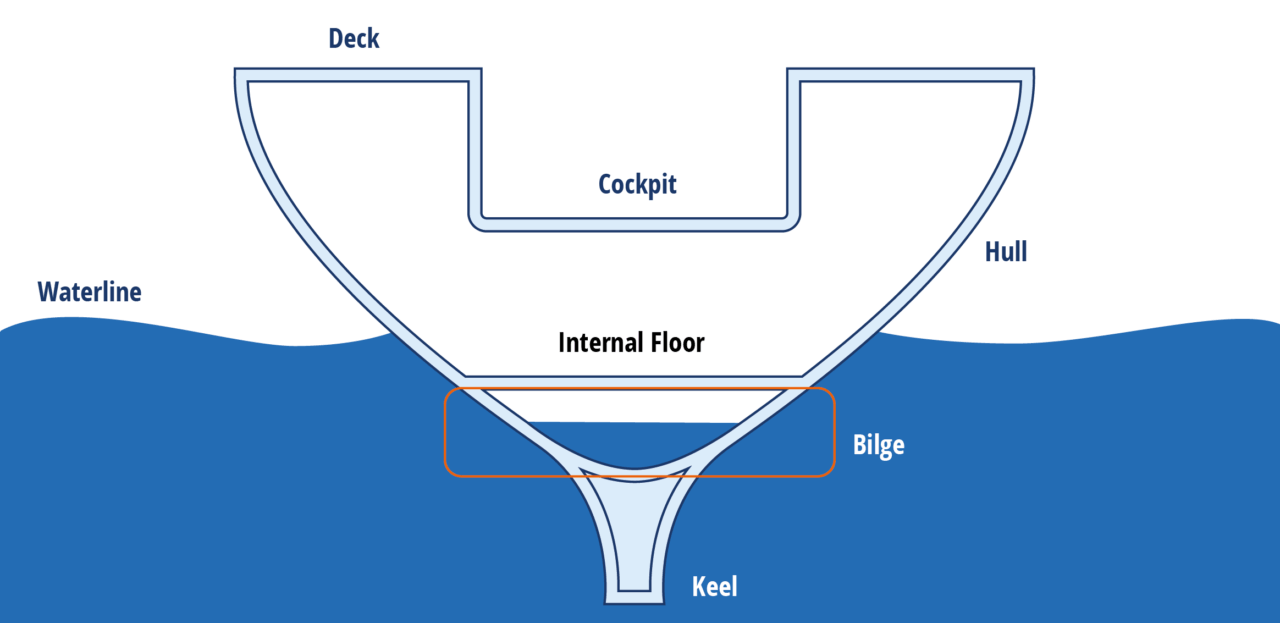

What is a ship bilge?

A ship bilge is the lowest part of a vessel’s hull where water, oil and debris collect, making it prone to corrosion and structural damage. Effective bilge maintenance involves using bilge repair techniques such as marine-grade epoxy repair and protection systems. These solutions help in repairing corroded bilge areas, preventing water damage, and extending the life of the bilge system in ship operations.

Can Belzona products be applied to the ship bilge while the ship is still in service?

Belzona’s cold-applied repair and protection materials, such as Belzona 1111 (Super Metal) and Belzona 5811 (Immersion Grade), are designed for in-situ application, meaning certain ship bilge repairs can be carried out without dry-docking. This makes them ideal for minimising downtime when addressing issues in the bilge system in ship operations.

Where can I purchase Belzona’s repair and protection solutions for ship bilges?

Contact your local authorised Belzona Distributor to purchase Belzona’s repair and protection solutions for ship bilges. To do this, please visit the Distributor Finder page on Belzona’s website and use the contact details provided.

Learn More

Belzona Blog: What is a Marine Coating?

Belzona Blog: Top 5 Steel Corrosion Protection Methods (with Videos)

Belzona Blog: How to Wrap Pipes Underwater with Belzona SuperWrap II

Contact Your Local Distributor to Learn More About Belzona Solutions for Ship Bilges

Chloe Hirst is the Senior Copywriter at Belzona Limited and is based in Harrogate, England. She gained a Bachelor’s Degree (with Hons.) in Media and Communications (specialising in Journalism) at Goldsmiths College, University of London. Chloe regularly writes case studies and thought leadership content featuring a variety of different industries, with a special focus on the renewables sector. In both 2023 and 2024, she won the Best Manufacturing Content Creation Specialist (UK) Award as part of Acquisition International’s Influential Businesswoman Awards.