Shaft repairs are not a new application for Belzona systems. In fact, you would be hard-pressed to think of an industrial environment where Belzona has not completed a shaft repair of some description. Whether it is excessive wear, corrosion of the metal or even electrolysis, Belzona solutions are able to help restore the damage and protect it for the long term. This is the case in the application below, which takes us to Texas, USA, for a repair to wind turbine generator shaft.

The impact of electrolysis on a shaft

Significant efforts are made within generators to reduce eddy current losses, namely because stray currents can have an impact on other components in the vicinity. This is further avoided by correct grounding of all equipment, thus safely drawing the eddy currents away.

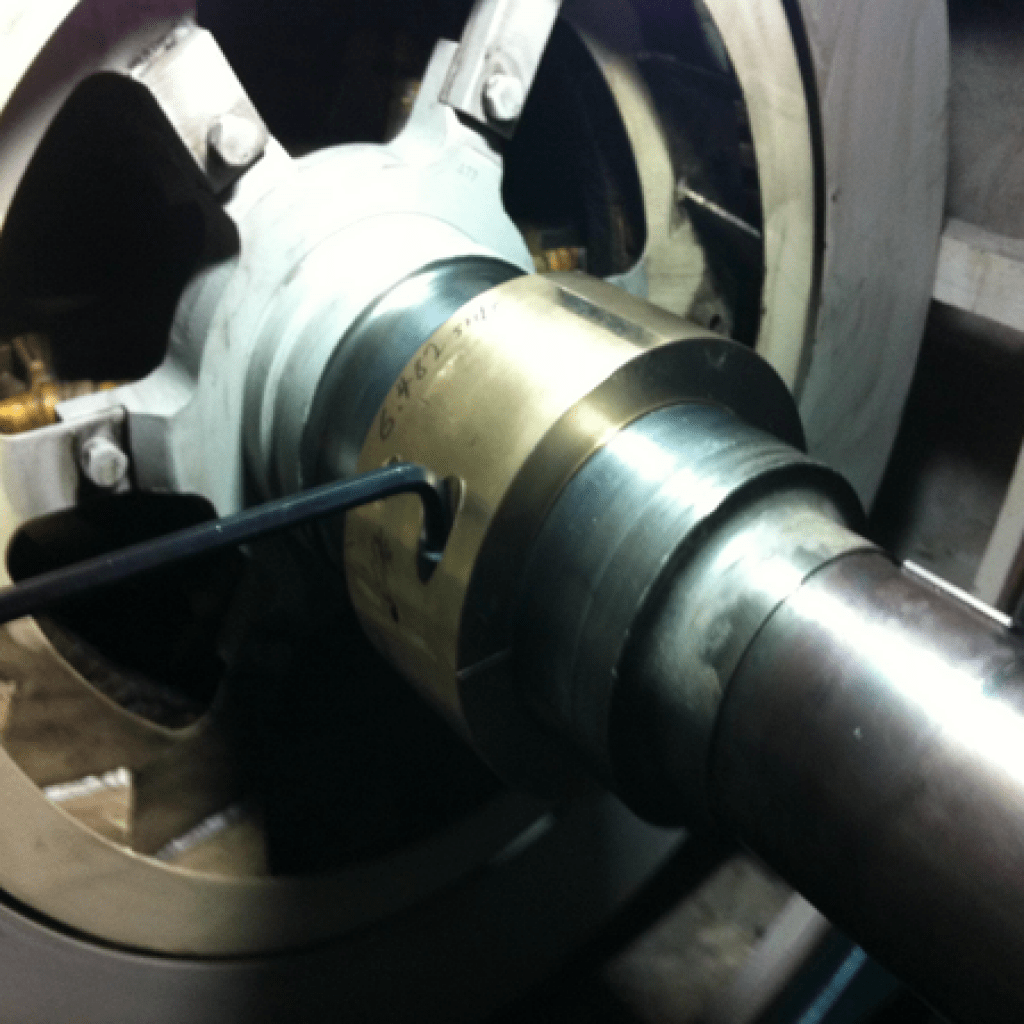

Due to ineffective grounding of the generator shaft in this wind turbine, stray eddy currents were being conducted by both the shaft and bearing. This caused electrolysis damage, resulting in severe pitting across the circumference of the shaft. Overall, the impact of this ineffective grounding had developed in destabilization of the turbine, altogether culminating in further wear to neighboring components.

Application date

December 2011

Products

The products used in this application included:

Belzona 9111 (Degreaser)

Belzona 9411 (Release Agent)

Application Method

Initially, the damaged shaft was prepared in line with Belzona’s recommended protocols. This includes cleaning the metal substrate, ridding it of any contaminants such as oil and grease. Moreover, it requires an angular profile to be prepared for optimal adhesion of the paste-grade material. When machining or grit blasting is not an option, such as in this instance, SSPC-SP11 Power Tool Cleaning to Bare Metal is acceptable to achieve this standard.

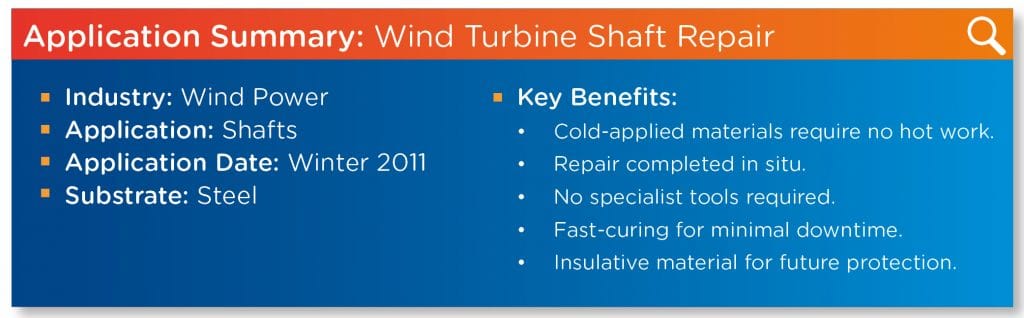

The pre-designed brass molds were coated in release agent in order to facilitate their clean removal after curing. Belzona 1111 was used to wet out the surface of the shaft and then built up to a peak on the surface prior to the installation of the molds.

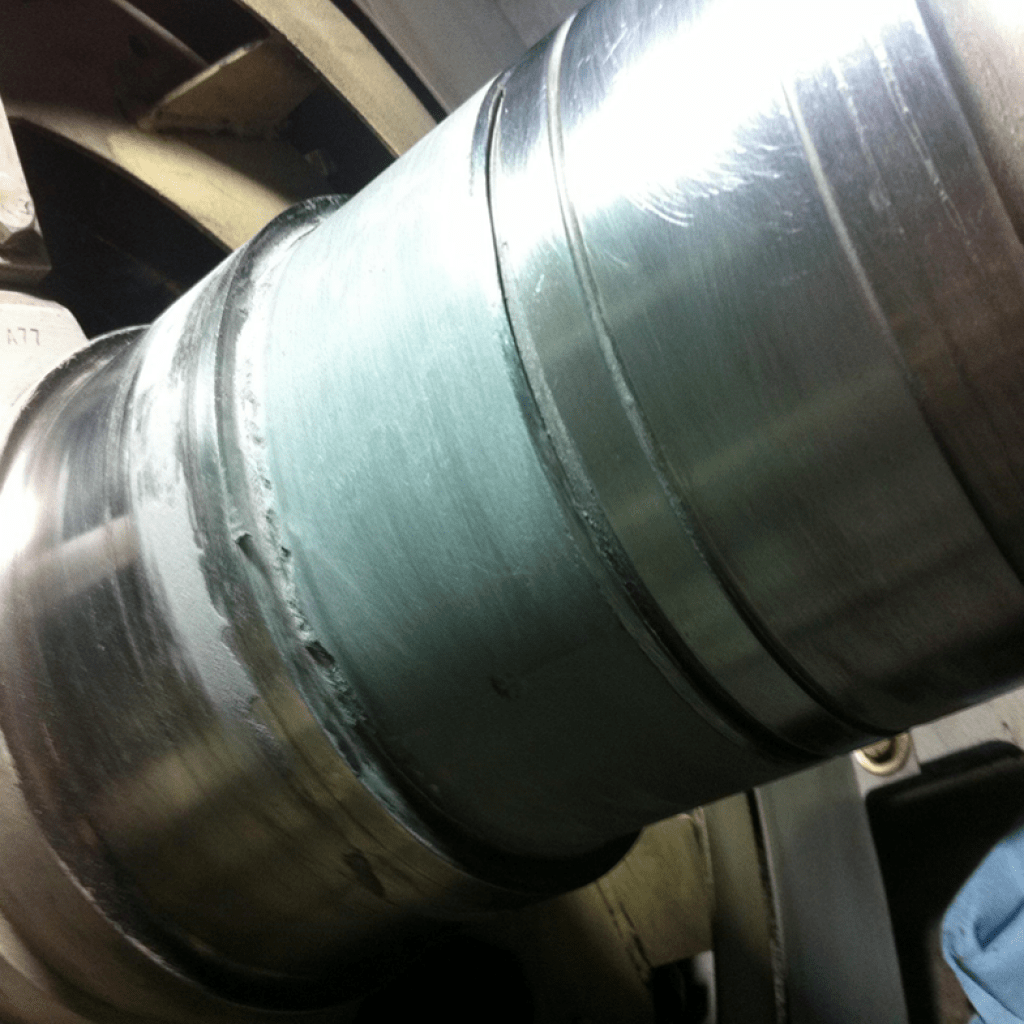

Following adequate cure of the material, the molds were removed revealing the restored shaft. Importantly, it was possible to sand Belzona 1111 in order to achieve the correct dimensions and shaft profile required. Altogether this application took less than a day to complete, avoiding significant downtime and ensured a rapid return to service.

Belzona’s Superior Shaft Solution

Three options were initially made available to the Customer. These included:

Replacement: Call a crane company and replace the generator shaft. Cost = $300,000 and 2-3 weeks of downtime.

Dismantle and repair: Call a crane company, lower the generator, transport it for welding repairs and reinstall. Cost = $275,000 and 2-3 weeks of downtime.

Belzona: Repair in situ using Belzona 1111, a cold-applied material. Cost (including product, labor and re-usable brass former) = $10,000 and 1 day to complete.

Out of three options available to the Customer, they were interested in the Belzona solution due to the significant cost-savings and minimal downtime. Using Belzona 1111 eliminated the need to dismantle the turbine and bring it to the ground, resulting in a minimum saving of $250K, over 20 times the cost of the Belzona solution.

In addition, this option removed the potential for the same damage to occur in the future. Belzona 1111 is both corrosion resistant and an excellent insulator. This ensures that, if there is a grounding malfunction, the shaft would not act as a conductor for stray eddy currents.

Longevity in service

Since the application in 2011, the shaft repair has been inspected twice, due to an unrelated gearbox failure. In both instances, the shaft was and still is, in perfect condition. In fact, this application method is now standardized for all of the energy company’s wind farms and they possess a range of former sizes to complete the Belzona repair.

Does this solution meet your requirements?

Contact us to find out more about our solutions for shafts.

View more applications in the Wind Power industry.