Troublesome 10% of Roofs

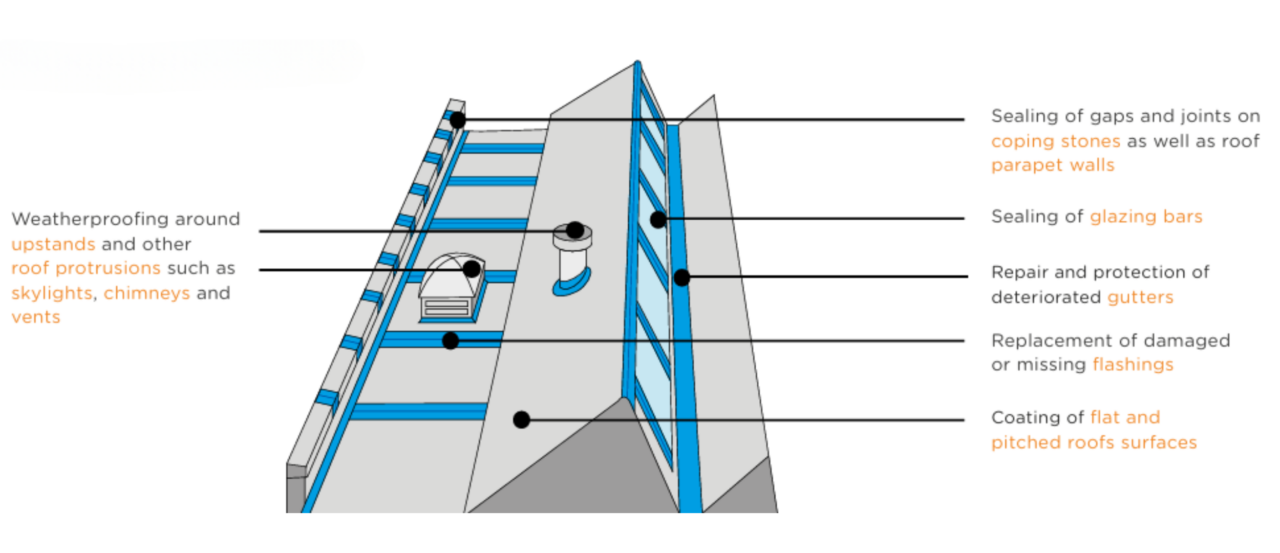

Belzona has identified that 90% of roof problems occur in only 10% of the roof areas. In particular, on flat roofs, the weight of pooled rainwater can lead to deflection, which can, in turn, cause structural damage. To address these challenges, microporous membrane weatherproof coatings offer reliable solutions for roof repair and maintenance. By forming a continuous and durable barrier, they help prevent common roofing issues associated with protrusions, joints, and seams, as well as glazing bars, skylights, and gutters, which often result from adverse weather conditions.

As membranes prevent water ingress while allowing trapped moisture underneath to escape, they enable asset owners to manage moisture control in buildings more effectively. In addition, UV-resistant waterproofing membranes shield buildings and structures from UV radiation, thereby reducing energy consumption.

Protrusion

Any extensions that penetrate through roofs require robust roof sealant materials to ensure durability and prevent leaks. Most sealers used around pitch pans or exhaust vents can crack due to plasticizer loss, ageing, vibration, or roof movement. The deterioration of these materials is due to adverse atmospheric conditions and nd improper surface preparation, such as failing to clean the flashings before installation.

A flashing roof leak or roof vent leak can also occur if the asset owners use materials of the wrong diameter. To repair roof flashings and other roofing components of the roofing systems, Belzona provides weatherproofing coating that adheres to various substrates and complex geometries, offering durable protection against environmental damage.

Joints and Seams

Building movement can affect structural integrity, especially at the joints and seams. This can result in leakage at roof expansion joints and seams. Microporous membranes can effectively address these issues, allowing joint movement while maintaining protective properties.

Glazing Bars/Skylight Sealants

Glazing bars and skylight sealants often fail due to natural expansion and contraction of roofs. Replacing the damaged skylight caulking will not solve the problem as it is likely to recall. Belzona provides liquid-applied membranes – a more permanent solution that offers excellent adhesion to various substrates, along with watertight, weatherproof, and UV-resistant properties.

Gutters

Gutters usually suffer corrosion due to stagnant water, leading to leaks at the joints, through bolt holes, or at the junction and the downspouts. To restore worn-out gutters, asset owners may consider a waterproofing membrane for a seamless transition from the roof to the gutter.

Belzona Breathable Membranes for Roof Repair and Maintenance

Belzona waterproofing membranes for roof repair and maintenance include Belzona 3111 (Flexible Membrane), Belzona 3121 (MR7), Belzona 3131 (WG Membrane).

Belzona 3111 (Flexible Membrane)

Belzona 3111 (Flexible Membrane) is a water-based single-component coating that serves as a long-term roof leakage solution. Its low-odor properties allow the applications in a variety of different environments without disrupting operations. In addition to its rain-resistant properties, Belzona 3111 (Flexible Membrane) exhibited high solar reflectance properties with an average SRI of 99.4%.

Belzona 3121 (MR7)

Belzona 3121 (MR7) is two-component waterproofing solutions for roof leak repair. The system is suitable for emergency repairs, providing protection against rainwater, infrared, and UV radiation. Its superior properties include immediate water-resistance capability after application. It can cure even in fully immersed conditions.

Belzona 3131 (WG Membrane)

Belzona 3131 (WG Membrane) is a moisture-activated urethane coating that can adhere to a wide range of materials. It is suitable for application in cold temperatures and cures down to 0°C (32°).

How To Apply Belzona 3111 (Flexible Membrane) for Roof Repair and Maintenance

STEP 1 – Surface Preparation for Roof Repair and Maintenance

Prepare the surface by removing all dirt, dust, loose materials, grease, oil, and other contaminants. Wash all non-porous surfaces with mild detergent and allow to dry. If required, use Belzona 9111 (Cleaner Degreaser) to degrease galvanized steel and glass.

STEP 2 – Surface Conditioner for Roof Repair and Maintenance

Select the appropriate surface conditioner based on substrate.

a. Use Belzona 3911 (PSC Surface Conditioner) for roofing felt, asphalt, brick, concrete and other porous or bituminous surfaces, and leave the conditioner until it is touch dry.

b. Use Belzona 3921 (GSC Surface Conditioner) on glass, slate, lead, copper, aluminum, and other non-porous surfaces except Plexiglas and other plastics. Then, leave the conditioner until it is touch dry.

STEP 3 – Use Reinforcement Sheet to add durability to the coating system

Lay out Belzona 9311 reinforcing sheet over the conditioned area. Belzona recommends using Belzona 9311 reinforcing sheet to add durability of the protective system.

STEP 4 – Application of Belzona 3111 (Flexible Membrane)

Apply Belzona 3111 (Flexible Membrane) with a soft bristled brush or spray over Belzona 9311 reinforcement sheet and allow the product to dry for around 2-4 hours.

STEP 5 – The Second Coat of Belzona 3111 (Flexible Membrane)

Once cured, apply the second coat of Belzona 3111 (Flexible Membrane) to give a smooth finish.

FAQ

Can waterproofing membranes for roof repair and maintenance be spray applied?

Among Belzona membranes for roof repair, Belzona 3111 (Flexible Membrane) is a water-based roof coating. The material is sprayable, making it suitable for large flat areas.

What is the most suitable material for emergency roof repair?

Belzona 3121 (MR7) is a weatherproofing liquid-applied membrane for emergency roof repair. The material bonds strongly to all common roofing surfaces including slate roofs, tile roofs, asphalt, felt, asbestos cement sheet roofs and metal roofs, even during adverse weather conditions. This system can resist to water immediately after application and cure in fully immersed conditions.

Contact Belzona to Find Out More about Roof Repair and Maintenance

Jake Stephenson originally joined Belzona in 2014 as a Service Support Technician and has since been promoted to Training Facilitator, based at the Company’s Headquarters in Harrogate. With over a decade of experience, Jake plays a key role in leading training workshops and demonstrating the correct application of Belzona repair composites and protective coatings. In addition to leading training courses, he contributes to the creation of sales aids, exhibition materials and product testing.

Jake has been actively involved in the development of many Belzona solutions, including Belzona 4141FR, Belzona 5711, Belzona 5721 and Belzona 1984. This involved testing formulations, refining application methods and assessing product performance in various climates and conditions. He has also participated in live demonstrations at open days in numerous locations including Harrogate, Poland and Germany; showcasing Belzona’s industrial repair and protection solutions.

Holding an AMPP (NACE) Certified Coatings Inspector Level 1, Jake ensures that Belzona’s training aligns with industry standards, providing Belzona’s authorised Distributor Network with expert guidance on surface preparation, application techniques and coating inspections. His technical expertise and hands-on experience make him an invaluable asset to Belzona’s global support network.

Irresistible! Thank you so much for this kind and good service.your services is better than better.