Video: Underwater Sealing of a Pipe Live Leak with Belzona 1212

Why Surface-Tolerant Repairs Matter

When equipment begins to leak or corrode in service, there is rarely time to achieve ideal surface conditions. Emergency repairs are often needed in damp, oily or hard-to-reach areas, such as offshore platforms, chemical plants or underground infrastructure, where traditional coating and bonding methods can’t cope.

This is where surface-tolerant epoxy repair materials make all the difference. Designed to adhere to contaminated or minimally prepared surfaces, they allow you to restore assets quickly, safely and cost-effectively, with minimal downtime.

Challenges of Conventional Repair Methods

Standard epoxy coatings and composites usually require:

- Grit blasting to SA2.5/NACE No. 2 for proper adhesion

- Dry, contaminant-free surfaces

- Long curing times, especially in cold weather

- Specialist tools and PPE, which are often unavailable in emergency settings

These strict epoxy surface preparation requirements make conventional systems difficult to apply in real-world conditions. If ideal preparation isn’t possible, repairs are likely to fail, leaving your equipment vulnerable and your maintenance budget under pressure.

Introducing Belzona 1212: Surface-Tolerant Epoxy

Belzona 1212 is a surface-tolerant epoxy for wet surfaces and oily substrates that gets equipment back in service with minimal downtime. Specifically engineered to have excellent adhesion to manually prepared substrates, even where grit blasting isn’t possible, this fast-curing epoxy is easy to mix and apply.

Key benefits:

- No grit blasting required – surface prep can be carried out with simple hand tools (SSPC-SP11)

- Effective for underwater epoxy repair and use on oil-contaminated steel

- Fast-curing epoxy – touch dry in 40 minutes at 20°C (68°F), return-to-service in 90 minutes

- Cures at low temperatures – down to 5°C (41°F)

- Ideal for emergency corrosion and pipe leak repair

- Solvent-free and easy to mix by hand

Belzona 1212 was engineered specifically as an epoxy for wet conditions where a surface-tolerant coating is required, enabling it to bond tenaciously to steel substrates even when surface preparation is minimal or the substrate is heavily contaminated with water.

How to Stop a Pipe Leak with Belzona 1212

This straightforward method demonstrates how epoxy pipe repair using Belzona 1212 can be carried out quickly and effectively. To see the full process, watch the YouTube video.

Step-by-Step Guide:

Step 1: Surface Preparation

First, abrade and roughen the entire repair area.

Step 2: Prepare Belzona 1212

Mix the Base and Solidifier of Belzona 1212 thoroughly until the material is streak-free.

Step 3: Apply Belzona 1212

Remove the plug from the bypass plate and put to one side. Now you can begin the pipe leak repair by firmly applying Belzona 1212 to the plate with a brush, pushing it well into the surface profile. Once you have applied the material to the plate, apply Belzona 1212 to the prepared bond area.

Step 4: Apply the Plate

Position the bypass plate down firmly over the repair area. Secure with cable ties and leave to cure.

Step 5: Insert the Plug

Stop the leak by inserting the plug and remove the cable ties to complete the repair.

Belzona 1212 In Action

Belzona 1212 has undergone extensive testing to demonstrate its strength and reliability in real-world conditions.

- Dolly Pull-Off Adhesion: Achieved loads of over 1800 kg (3968 lbs) after full cure, even on wet or oil-contaminated surfaces.

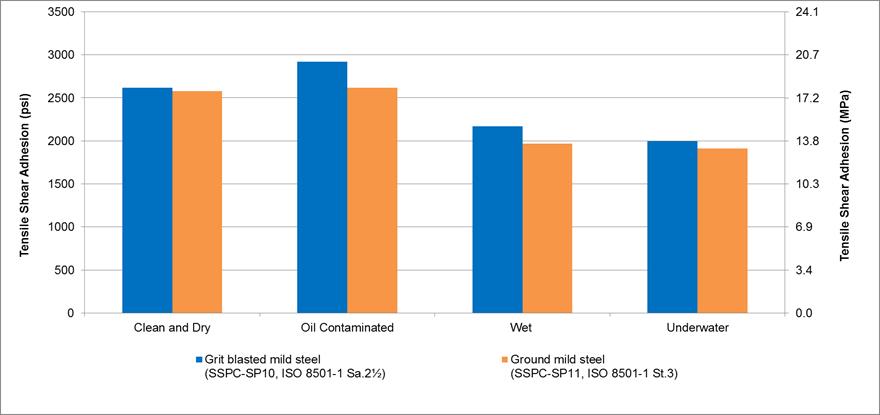

- Tensile Shear Adhesion: Excellent performance even on oil-contaminated steel.

- Rapid Load Bearing: After a 90-minute cure at 20°C (68°F), a 1-inch bracket bonded with Belzona 1212 supports >200 kg (440 lbs); after 4 hours, this increases to 1000 kg (2204 lbs).

- Toughness and Durability: Designed for long-term in-service performance.

Figure 1: Adhesion of Belzona 1212 to contaminated mild steel surfaces prepared to SSPC-SP11/ISO 8501-01 St3 (power tool cleaned)

FAQs

Can Belzona 1212 be applied to wet or oily surfaces?

Yes Belzona 1212 is a surface-tolerant epoxy designed specifically for bonding to oil-contaminated and damp surfaces.

What is the best epoxy for emergency repair in cold weather?

Belzona 1212 is one of the most effective emergency epoxy repair products for cold climates. It cures at temperatures as low as 5°C (41°F) and becomes touch dry within 40 minutes at 20°C (68°F), allowing for fast return-to-service. This makes it a highly practical choice for engineers dealing with unexpected leaks or corrosion during winter or in refrigerated facilities. Its fast cure time and excellent mechanical strength make Belzona 1212 the go-to epoxy for pipe repair when time and temperature are critical factors.

Where can you purchase Belzona 1212?

Contact your local authorised Belzona Distributor to purchase Belzona’s surface-tolerant epoxy solutions. To do this, visit the Distributor Finder page on Belzona’s website and use the contact details provided.

Learn More

Tank Leak Repair: A Complete Guide

Contact Belzona to Learn More about Tank Base Sealing

Henry Smith

Senior Technical Service Engineer

Belzona Polymerics Ltd