INTRODUCTION TO ABRASION

Abrasion-resistant systems can protect your equipment from a potential damage and ensure a long-term uninterrupted service.

What is abrasion?

The word abrasion comes from the Latin “abradere” which means “to scrape away, shave off”. Abrasion is the process of wearing down and rubbing away due to exposure to normal use or exposure to external abrasive elements. There are different types of abrasion. In this post, we will focus on mechanical abrasion which creates various challenging situations disrupting the normal operations of equipment. The problem of abrasion is especially present in such industries as mining, pulp and paper, wastewater. In these industries, where the presence of abrasive media (rocks, sludge, wastewater) is inevitable, the protection of the equipment is key to providing an uninterrupted service.

Understanding abrasion

Talking about abrasion, it is important to understand the correlation between erosion and abrasion.

Erosion is defined by ASTM as “damage to a solid surface, generally involving progressive loss of material, caused by the relative motion between the surface and a contacting substance or substances”. In most instances, the material removal is a gradual process. Many parameters must be considered when assessing erosion, including entrained particle size and shape, the angle of impact and velocity, particle concentration, and service temperature among others.

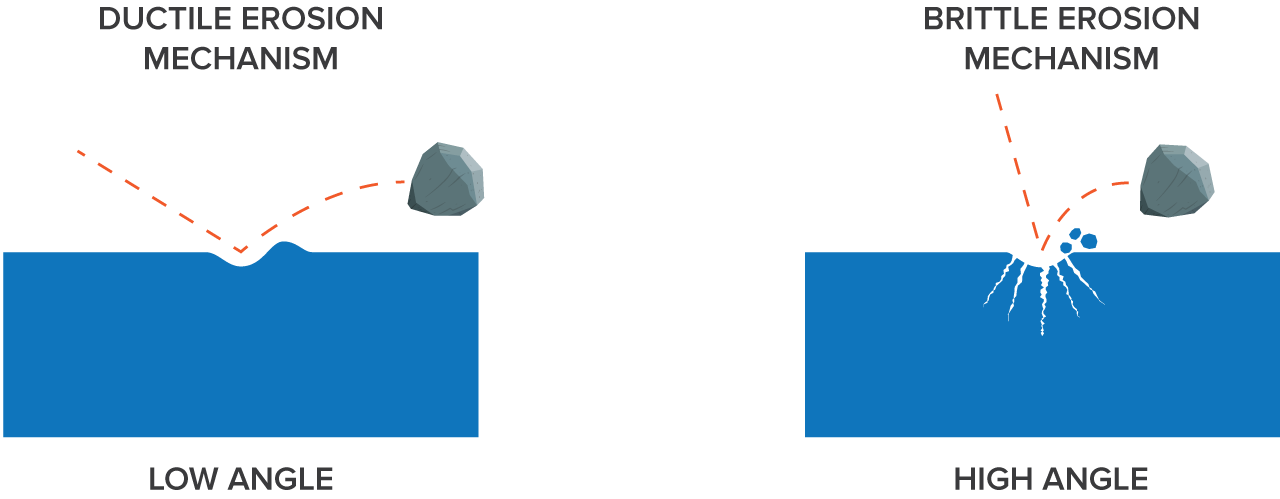

Brittle erosion vs. ductile erosion

The different mechanisms of erosion are divided into brittle and ductile behavior, as depicted below. Brittle erosion pertains to material removal due to a radial crack formation and wearing via impact abrasion and tends to occur when the angle of impingement is perpendicular to the affected surface. Ductile erosion, on the other hand, deals with material removal due to cutting or ploughing via sliding abrasion where the angle of impact is typically less than 30° with respect to the target surface.

Types of equipment affected by erosion

Ductile is the predominant erosion mechanism when the impingement angle of attack is low. This is the case of straight pipeline and piping components or vessels where the entrained solids impinge at a shallow angle of attack. However, for entrained solid impingement angles greater than 60⁰, brittle erosion is predominant. This is typical of piping components with other geometries such as elbows and bends. It is worth mentioning that this categorization of erosion behavior as ductile or brittle is not absolute. Erosion, whether of ductile or brittle nature, can dramatically affect the serviceability of any piece of equipment, leading to interrupted operations, costly shutdowns, and recurrent safety and environmental hazards among others.

Although erosion cannot be completely eliminated, comprehensive erosion mitigation strategies could be effectively implemented by designers, engineers, and operators to extent the service life of the equipment.

[Sources: ASTM International (2010), ASTM G40 Standard terminology relating to wear and erosion, Tilly G.P, (1973);

A two stage mechanism of ductile erosion. Wear, Vol 23 1973, p 87–96.]

BELZONA HOW-TO

In our previous blog post “Pulp and Paper: 4 Key Maintenance Areas”, we spoke about various repair and protection methods, including creating comprehensive abrasion-resistant systems. Due to highly destructive nature of erosion and abrasion, the repair process often requires a multi-step procedure.

In this post we demonstrate one of the procedures for an abrasion-resistant system application.

DRAWING: BELZONA ABRASION RESISTANT SYSTEM

BELZONA SOLUTIONS NEEDED FOR AN ABRASION RESISTANT SYSTEM

Belzona 1311 , a ceramic epoxy-based composite for the metal repair and erosion-corrosion protection, was used to rebuild the profile of the repair area.

Belzona 5821, an epoxy-based coating, was used as a bonding agent and applied prior to the application of alumina tiles.

Belzona 9811 – alumina tiles made from superfine, micro-crystal aluminum oxide used to create a hard wearing abrasion-resistant lining.

Belzona 1812, an abrasion resistant lining created for the repair and lining of metal surfaces, was used as a grouting material for encapsulating the tiles.

Yulia Burova, Marketing Director, Belzona Inc., Miami FL, USA