Loose anchor bolts pose a threat to industrial reliability, leading to machinery movement and misalignment that undermines component integrity, workplace safety, and operational performance. In many cases, epoxy concrete repair can offer solutions to restore the bond between anchor bolts and the surrounding concrete, thereby improving workplace safety and operational productivity.

What Are the Causes of Loose Anchor Bolts?

The loss of anchorage capacity is typically a consequence of the following conditions:

- Persistent vibration and cyclic loading during operation which fatigues the concrete and anchor bolt interface

- Progressive chemical exposure and corrosion mechanisms that degrade the machinery’s anchor points and connections.

- Environmental attack such as water ingress, sub-zero temperatures, or freeze-thaw cycling can deteriorate the concrete durability, leading to spalling, cracking, and a loss of support around the anchor bolts

These are common scenarios in a variety of industrial facilities such as mining, and pulp and paper. Such failures can escalate workplace risks and create unsafe working environments.

Concrete Repair Methods for Anchor Bolts in Concrete Foundation

For repairing loose anchor bolts and remaking or installing anchor bolts in concrete, pourable or injectable concrete materials are the most suitable options. They allow for applications where it is difficult to withdraw the loose bolts or where access is limited.

Belzona recommends Belzona 4000 Series, which includes high-performance solutions for rebuilding and resurfacing concrete and stonework. These products adhere to a wide range of substrates, including brick, marble, stone, steel, and other metallic substrates. The Belzona 4000 Series consists of multiple epoxy concrete repair systems, each designed to suit different service conditions, including:

- Exposure to chemicals

- High temperatures

- Heavy loading

- Abrasive wear

- Requirement for waterproofing

In the following section, Belzona demonstrates how to install anchor bolts in a concrete foundation with Belzona 4111 (Magma-Quartz). Belzona 4111 (Magma-Quartz) is a three-part epoxy concrete repair system, consisting of Belzona 4151 (Magma-Quartz Resin) Base and Solidifier, and Belzona 4111 (Magma-Quartz) aggregate.

How To Use Epoxy Concrete Repair Products for Securing Loose Anchor Bolts

Step 1: Preparation to Restore Misaligned Anchor Bolts

For loose bolts that cannot be withdrawn, drill an access hole at a 45˚ angle to meet the bolt. Then remove all dust and debris from the hole. If the concrete is wet, force-dry the area before application. The moisture content must be below 6% for the application of Belzona epoxy concrete repair materials.

Step 2: Mix Belzona 4151 (Magma-Quartz Resin) Base and Solidifier

Mix the Belzona 4151 (Magma-Quartz Resin) Base and Solidifier in a 2:1 volume ratio or a 2.3:1 weight ratio. Belzona recommends strictly following the manufacturer’s Instructions for Use to ensure optimal results.

Step 3: Add Belzona 4111 (Magma-Quartz) Aggregate into the Mixed Resin

Add Belzona 4111 (Magma-Quartz) aggregate to the mixed resin until the mixture achieves a pourable consistency, suitable for filling the voids around the loose anchor bolts.

Step 4: Application of Belzona 4111 (Magma-Quartz) for Anchor Bolt Repair

Use a funnel to aid in pouring Belzona 4111 (Magma-Quartz) into the anchor bolt voids and gaps.

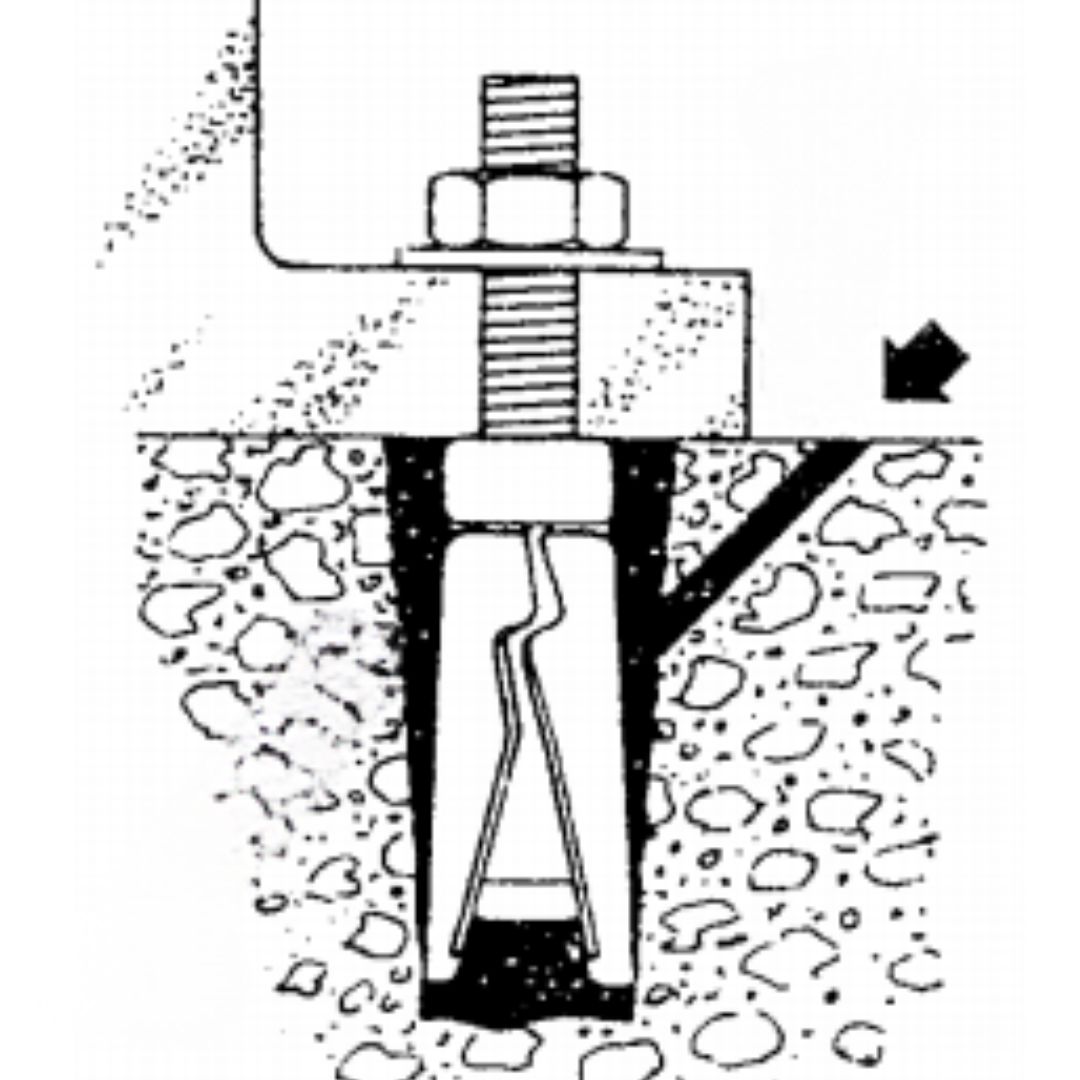

Alternatively, pour the mixture into a cartridge, cut the tip, attach a nozzle, and inject the material directly into the void around the anchor bolt holes.

For larger gaps or where movement is restricted, mix the product to a thicker, more viscous consistency and pack it firmly around the anchor bolts. Use a steel float to level off the product.

How To Use Epoxy-Based Concrete Repair Materials for Remaking or Installing Anchor Bolts in Concrete

Step 1: Preparation Before Applying Materials for Anchor Bolt Installation

For remaking or making new anchorages for machinery installation, mark out the positions of the required anchorage points. If the existing holes are being used, enlarge the holes to expose fresh, sound concrete. After drilling, thoroughly remove dust and debris using a brush and vacuum.

Clean the anchor bolts with a brush to remove surface dust. Use Belzona 9111 (Cleaner Degreaser) to degrease the anchor bolts and allow them to dry.

Step 2: Mix Belzona 4151 (Magma-Quartz Resin) Base and Solidifier

Combine Belzona 4151 (Magma-Quartz Resin)base and solidifier, following a 2:1 ratio by volume or 2.3:1 ratio by weight. Belzona recommends strictly following the manufacturer’s Instruction for Use to ensure optimum results of anchor bolt installation.

Step 3: Add Belzona 4111 (Magma-Quartz) Aggregate into Belzona 4151 (Magma-Quartz Resin)

Add Belzona 4111 (Magma-Quartz) aggregate into the mixed resin until the desired consistency is achieved, suitable for pouring into the anchor bolt holes.

Step 4: Pour Belzona 4111 (Magma-Quartz) into the Anchor Bolt Gaps

Once the desired pourable consistency is achieved, slowly pour the Belzona 4111 (Magma-Quartz) mixture into the holes, allowing the product to evenly fill the spaces within the holes.

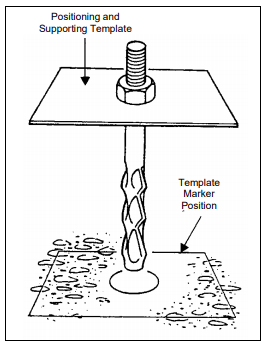

Step 5: Ensure the Proper Vertical Position of the Anchor Bolt Installation

While the product is still within its working life, insert wooden alignment gaskets to ensure the anchor bolts remain in a completely vertical position.

Step 6: Insert the Anchor Bolt into the Hole

Then, insert the anchor bolt into the hole completely and allow the product to cure. Once the product cures, remove the wooden gaskets using a screwdriver or another suitable tool.

Step 7: Tighten the nuts and bolts

Then, insert the washers and nuts into each bolt. With a torque wrench, tighten the nuts until the desired torque is achieved.

Learn More

Belzona Reinforces Crusher Foundations at Brazil Copper Mine

Epoxy Concrete Repair Method: How to Repair Equipment Foundations

Epoxy Concrete Repair: How to Fill Voids in Concrete

How to Fix Uneven Concrete Floors (With Video)

Frequently Asked Questions

Can I fix a loose bolt in concrete without removing it?

Yes, when anchor bolts cannot be removed, Belzona recommends using epoxy concrete repair materials to restore the stability of the machinery installation. The systems are based on a range of epoxy resin materials and selected aggregate, allowing for the adjustment of material consistency to ensure a pourable consistency for filling gaps around anchor bolts.

How can I select the most appropriate epoxy concrete repair method for restoring misaligned anchor bolts?

The suitability of the materials for anchor bolt repair depends on the service conditions and the operating environment. The Belzona 4000 Series comprises a range of epoxy-based concrete repair materials, each designed for different performance needs.

For remaking or new anchorage installations, Belzona provides how-to videos as follows:

Can Belzona 4000 Series repair other types of damage on concrete substrates?

Yes, the Belzona 4000 Series can be applied to a wide range of substrates, including brick, marble, stone, steel, and other metallic substrates. Typical applications include:

Where can I find Belzona products and services?

Belzona operates through a network of over 160 Distributors, available in over 120 countries. Through the ‘Belzona Product Plus’ approach, Belzona Authorized Distributors provide not only local stock availability but also onsite training, ongoing technical support, and aftercare service. Visit Belzona Distributor and Supplier Finder to find the Belzona Authorized Distributor in your area.

Contact Belzona to Learn More About Epoxy Concrete Repair

Marketing and Distributor Support Coordinator at Belzona Limited, based in Bangkok, Thailand