INTRODUCTION TO CRACKED ENGINE BLOCK REPAIR

A cracked engine block in a vehicle is not uncommon. What might seem like a disastrous situation, does not necessarily mean the end of the engine’s lifespan. The cracks can lead to a series of problems, for that reason they need to be eliminated. Therefore, there are various methods of repairing cracked engine blocks: from welding and brazing, to cold metal stitching. Belzona offers a solution that does not require hot work or specialist tools.

WANT TO LEARN HOW TO BOND METAL TO METAL WITHOUT WELDING

Click here to find out

BELZONA HOW – TO

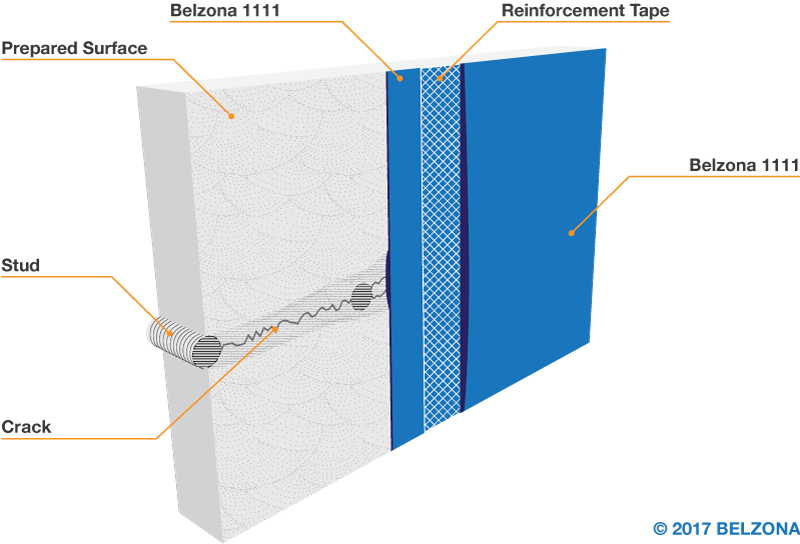

For the repair of this cracked engine block, we used Belzona 1111 (Super Metal), Belzona 9111 (Cleaner/Degreaser), Belzona 9341 (Reinforcement Tape), and a few tools from our machine shop. The engine had a few hairline spider cracks. After the surface was thoroughly cleaned, and the cracks were terminated by drilling and tapping small holes at their ends. Studs were then threaded into the holes and cut flush with the casing. The cracks were veed out with a grinder, and the repair area was thoroughly roughened. Belzona 1111 was mixed and applied directly onto the cleaned surface. A small piece of reinforcement tape wetted out with the mixed material was applied over the crack and encapsulated into the Belzona material already applied. Remaining mixed material was applied onto the entire area to create a buildup of approximately 1/8″ (3 mm). The entire application took less than an hour.

Drawing: Cracked Engine Block Repair with Belzona 1111

How To Repair a Cracked Engine Block

VIDEO: CRACKED ENGINE BLOCK REPAIR

SUPPLIES AND TOOLS USED FOR THIS CRACKED ENGINE BLOCK REPAIR

STEP-BY-STEP INSTRUCTIONS OF CRACKED ENGINE BLOCK REPAIR

BELZONA 1111 APPLICATION

Frequently Asked Questions

What causes a cracked engine block?

Cracked engine blocks in industrial diesel engines commonly used across the marine industry, in mining and heavy equipment and other heavy duty automotive and industrial trucks, usually occur due to a loss of casing integrity, which often causes cooling water leakage. This could be due to:

- Frost damage: When cooling systems are exposed to freezing conditions without adequate antifreeze protection, the water inside expands as it freezes, putting pressure on the block causing cracks.

Cavitation and corrosion: In poorly maintained systems where coolant flows are high speeds, cavitation can become a problem. Vapor bubbles can implode and damage internal surfaces. If this is combined with corrosion it can weaken the block and eventually lead to cracking over time.

Impact damage: Physical shock from collisions, dropped parts during maintenance, or operational accidents can cause structural fractures in the engine casing.

What are the symptoms of a cracked engine block in industrial machinery?

Industrial engines such as Caterpillar (CAT), Cummins and MAN Energy Solutions used across marine vessels, mining equipment, power generators, and heavy-duty vehicles, a cracked engine block can manifest through several operational and maintenance issues:

Pressure irregularities: Operators might observe abnormal pressure readings in the cooling system or crankcase due to cross-contamination or compression leakage.

Unexplained coolant loss or visible external leaks: Coolant escaping through hairline cracks in the engine block may result in puddles, staining, or pressurized leaks, especially noticeable after shutdown.

Overheating during operation: Reduced coolant circulation due to internal leaks can lead to abnormal temperature spikes or engine shutdowns caused by thermal overload.

Contaminated fluids: A cracked engine block may allow coolant and oil to mix, leading to milky or discolored oil, or coolant with oil contamination. This is often seen during fluid inspections or servicing.

Loss of compression or reduced performance: Internal cracks can affect cylinder sealing, leading to poor combustion, misfiring, or a noticeable drop in engine power.

Is a cracked engine block worth fixing?

In many cases, especially within industrial repairing a cracked engine block can be significantly more cost-effective than replacement.

A great example is the repair of a Komatsu 900 loader engine using Belzona 1111 (Super Metal)where a cracked engine block that would have cost $127,000 (at the time of the repair) to replace was instead repaired using less than 6 % applying Belzona products. The repair was completed in just four hours, minimizing downtime and saving both time and capital.

Read the case study here: https://khia.belzona.com/khia/_ENGINE_REPAIR_WITH_BELZONA

In industrial situations, replacing a large diesel or marine engine block can require extensive disassembly, long lead times, and lost production time. In-situ repairs using cold-applied solutions like Belzona, provide durable, fast, and cost effective alternative.

This solution does depend on the location and the extent of the damage and also the operating conditions. Contact a Belzona representative to find out more.

Can you save a cracked engine block?

Yes, cracked engine blocks can be saved. One method which has been successful in industrial situations for decades is to use a product such as Belzona 1111 (Super Metal), Belzona 9341 Reinforcement Tape, and standard machine shop tools to repair hair line cracks. This solution not only restores the casing’s strength, but also avoids a costly replacement, saving time, money, and operational downtime.

Want more information?

Visit www.belzona.com/metal-repair for more information

Contact Your Local Distributor to Learn More About Belzona Solutions

Belzona’s epoxy solutions can be used to repair cracked engine blocks. Belzona also offer solutions to an extensive range of engineering problems and repair situations

Interested in purchasing Belzona’s epoxy-based composites?

Yulia Burova, Marketing Director, Belzona Inc., Miami FL, USA

Bonjour,ayant un bloc moteur fissuré pouvez vous m indiquer un garage qui utilise vos produits en vie de faire réparer.merci

Bonjour, merci pour votre commentaire! Veuillez utiliser notre page Web de recherche de Distributeurs pour trouver votre Distributeur local. https://belzona.com/en/about/disfinder.aspx

Cordialement, l’équipe Belzona.