Pumps are used throughout the mining industry for a melange of processes, from the transport of slurry, to the pumping of subsoil water. Slurry pumps are one of the pieces of the equipment most susceptible to abrasion wear. Due to the harsh operational environments and the tough heavy-duty surface and underground mining processes, the early failure of slurry pumps used in the transportation of abrasive solids in large volumes is a common issue.

When critical slurry pumps go offline unexpectedly, a large mine can experience an exponential loss in revenue. Even though in recent years there has been significant progress with regards to the mechanical design of slurry pumps, they are still plagued with erosion issues and abrasion is one of the main threats to their longevity and performance.

Abrasion is caused by foreign bodies moving over a surface. In most cases these are mineral particles, which can be harder or softer than the metal surface undergoing the abrasion wear.

According to a Belzona Technical Service Engineer, even though handling abrasive fluids presents a tremendous challenge to any protective material, a carefully selected abrasion resistant coating can reduce impact wear effects, extend the life of the pump and optimize the overall performance of the pumping process.

There are many forms of abrasion, with many different names such as gouging, grinding and scratching. These names mainly describe the cause of the abrasion, and how the wear took place. Scratching abrasion could be due to small particles flowing through a pump; grinding abrasion could be a process involving particles under a compressive load.

Belzona’s abrasion-resistant protective coating products are designed to slow down the abrasion process in the pump as they are formulated to address these specific needs.

Belzona Abrasion Resistant Coatings in Action

A couple of years back, an Australian nickel and cobalt producer was in constant need of a reliable restoration and efficiency enhancement solutions for its refinery centrifugal vertical slurry pumps.

According to Rezitech Services, a Belzona Authorized Distributor in Australia, the refinery processes nickel and cobalt-bearing later items purchased from third-party mines in New Caledonia, Indonesia, and the Philippines.

Nickel ore is dried, ground, roasted, and leached in an ammonia solution to extract the nickel and cobalt in the processing plant.

The nickel and cobalt are then separated and further refined in the metal refining area.

One of the most critical pumps of the refinery is the 12 inch Hazelton VDS slurry pump used to extract and transport the ore from the primary tailing sump and distribute it to the process units for refinement. The slurry mixture contains approximately 60% solids by volume and has a temperature of 70C-80C.

Since the pump is running continuously 24 hours a day and due to the extreme wear, a second pump is required to be constantly in-situ as a standby unit. For this to be ensured, a third pump is used as a spare rotatable unit.

After 2500 hours of continuous operation, the operational unit that has been running will be replaced by the second unit. This second standby unit will then be replaced by the third spare pump and the removed pump will be stripped and inspected.

“An uncoated volute was put into service in 2013, and was almost irreparable after 5000 hours,” Rezitech Services North Queensland Manager said.

Belzona 1818

Belzona has released a new abrasion resistant fast curing epoxy based material specifically designed for mining and quarrying industries.

Learn more

Pump cutwater rebuilt and protected against abrasion

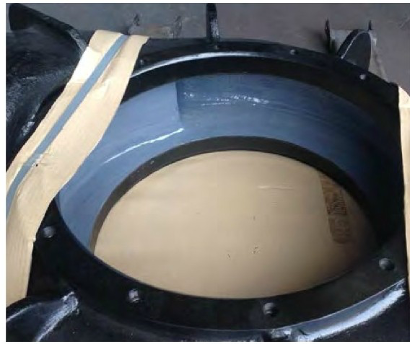

A set of four erosion and corrosion resistant Belzona composite repair materials and protective coatings has been proven to fulfill the imperative abrasion and temperature resistance requirements of the nickel cobalt operation’s pumps. Worn cutwaters were repaired with Belzona 1311, a paste-grade ceramic filled epoxy-based repair composite for rebuilding and re-profiling of damaged areas. Once cured, the cutwaters were shaped to the required dimensions using an angular grinder.

Belzona 1321, a ceramic-filled epoxy coating designed to protect against moderate abrasion, was applied to the entire casing internals as a priming coat, while Belzona 1812, an epoxy-based composite material that had been formulated with highly hard ceramic aggregates closely packed in a polymeric binder, was then applied.

A ceramic filled epoxy coating designed to provide erosion and corrosion resistance of metal surfaces.

A final layer of Belzona 1391, specifically designed for equipment that operates at high temperatures under immersion, was also applied throughout the entire pump internals to provide additional heat resistance.

“From start to finish, the application lasted less than a week and with simplified application techniques, the customer was able to avoid replacement costs in excess of approximately USD15,000,” a Belzona Technical Service Engineer said.

“The repair solution cost approximately half of this amount and prevented revenue loss due to downtime in the amount of USD77,000 per hour.”

Belzona’s epoxy solutions can be used to protect slurry pumps. Belzona also offer solutions to an extensive range of engineering problems and repair situations.

WANT MORE INFORMATION?

Interested in purchasing Belzona’s epoxy-based composites?

Yulia Burova, Marketing Director, Belzona Inc., Miami FL, USA