Understanding the Importance of Pipeline Coatings

Pipelines are essential to industries ranging from oil and gas to water treatment. However, these assets face constant exposure to harsh environments, which can lead to corrosion, erosion, impact, and chemical attack. To extend their service life and maintain efficiency, contractors and maintenance teams rely on pipeline coatings, protective systems designed to safeguard internal and external pipe surfaces.

Why Pipelines Need Protection

Every pipeline is exposed to conditions that cause gradual deterioration. Substances transported inside the pipes, such as water, wastewater, oil, or chemicals, can corrode or erode the internal surfaces. Externally, environmental factors like saltwater or high humidity accelerate corrosion, especially in offshore facilities or coastal plants.

Without proper protection, these factors can lead to leaks, pressure drops, and costly shutdowns. This is where Belzona’s pipeline coating systems come in, offering durable, cold-applied protection for a wide range of operating environments.

Step-by-Step: How Pipeline Coatings Work

- Surface Preparation

The surface must be cleaned and roughened to ensure strong adhesion. Belzona materials can bond to metallic, concrete, or composite substrates without the need for hot work. - Application of the Coating

The selected coating, such as a Belzona epoxy system, is applied to form a seamless, impermeable barrier. This step can be completed using brushes, rollers, or spray equipment. - Curing and Inspection

Once applied, the coating cures to form a tough, chemical-resistant layer. Inspection ensures the correct film thickness and full coverage have been achieved. - Service Return

After curing, the system can be placed back into service quickly, minimizing downtime and maximizing productivity.

Types of Pipeline Coating Solutions

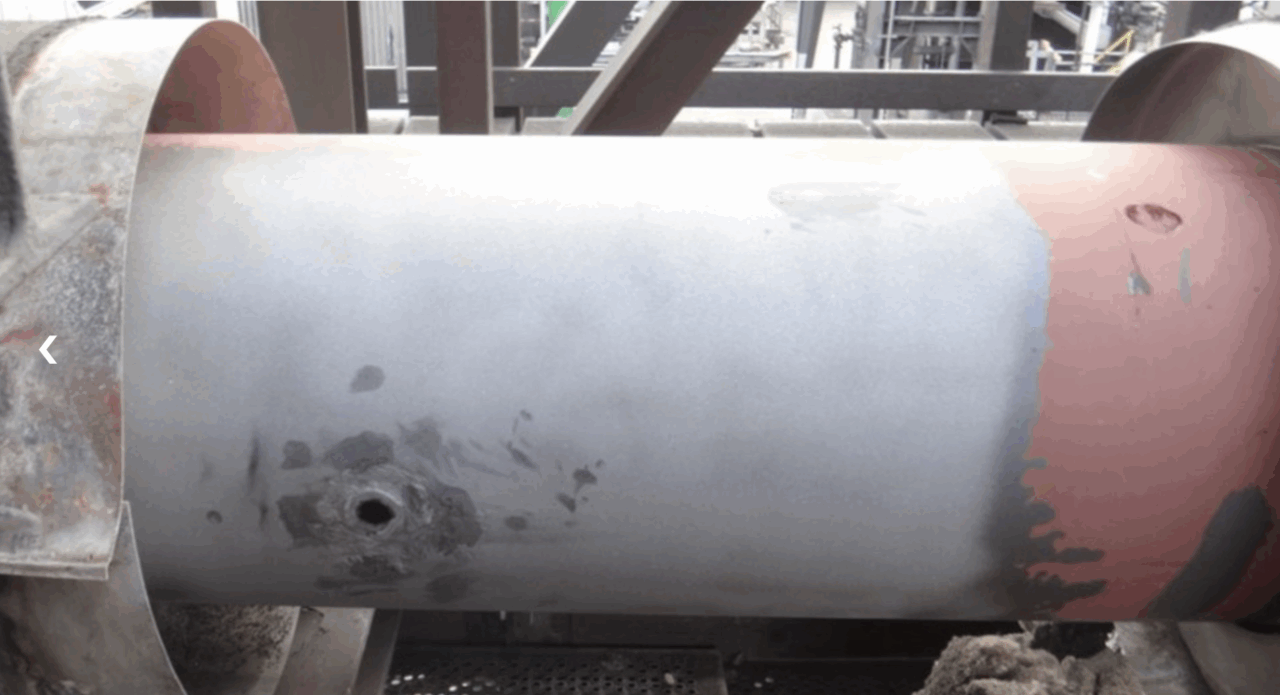

- Leak Sealing: Epoxy coatings can seal both liquid and gas leaks, preventing environmental hazards and pressure loss.

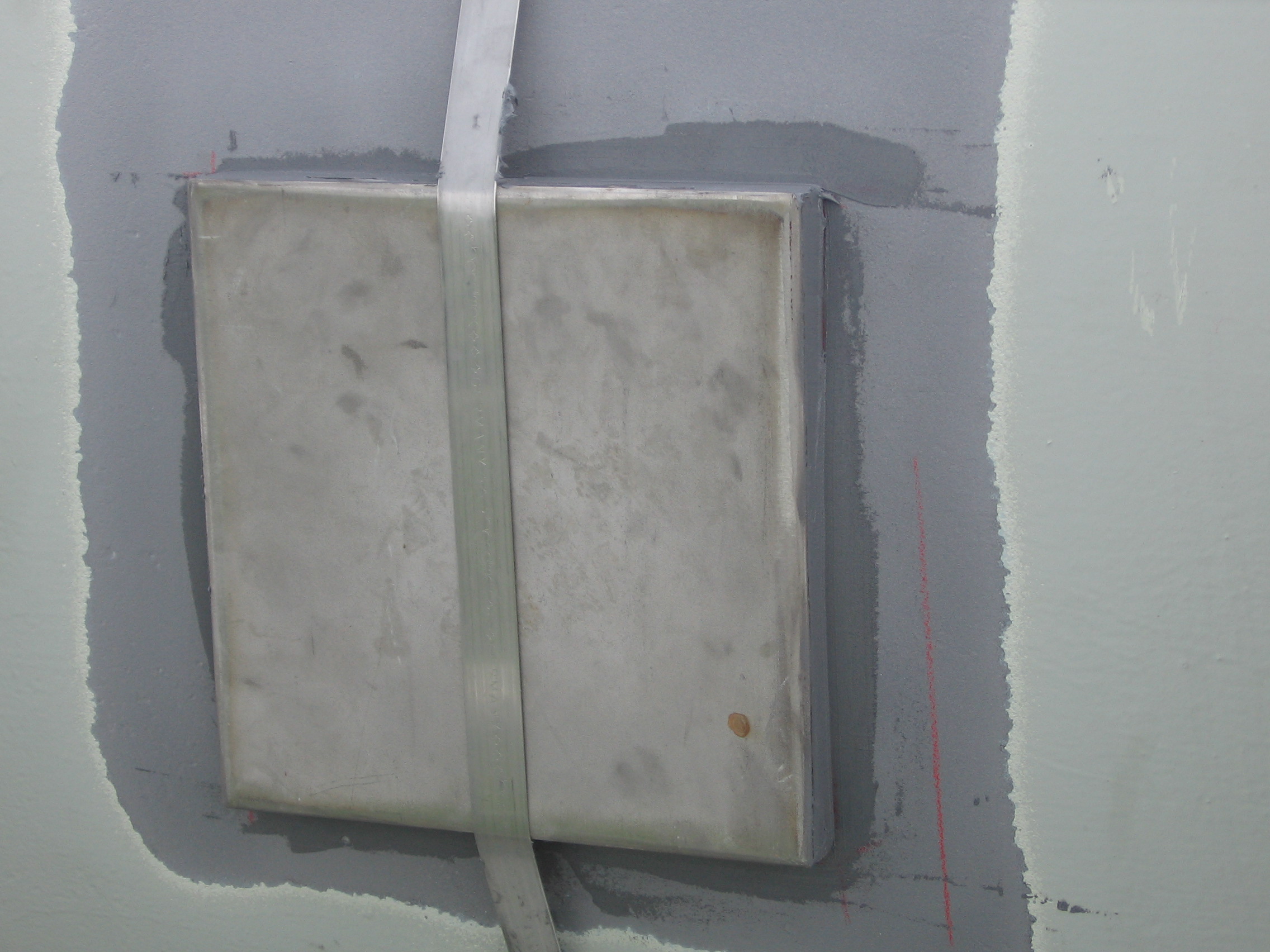

- Plate Bonding: Belzona’s structural adhesives bond and seal metal components, serving as an alternative to welding.

- Composite Wrapping: Reinforces weakened or holed pipelines, restoring strength and chemical resistance.

- Corrosion Protection: Pipeline corrosion protection coatings create a barrier against moisture, salt, and chemicals, including Corrosion Under Insulation (CUI).

- Immersion-Grade Coatings: Some systems are formulated to be applied and cured underwater, ideal for offshore and marine assets.

- Internal Lining: Internal pipeline coating systems improve flow efficiency through hydrophobic properties while resisting erosion and corrosion inside the pipeline.

Belzona Pipeline Coatings

Belzona 1331: A coating system for erosion and corrosion protection of equipment operating under continuous immersion up to 50°C (122°F).

Belzona 1341: An internal pipeline coating system designed to improve the efficiency of fluid handling equipment and to protect metals from the effects of erosion-corrosion.

Belzona 1381: A coating system designed to protect equipment operating under immersion from erosion and corrosion damage at high temperatures up to 95°C (203°F).

Belzona 1391S: A sprayable pipeline coating system for equipment operating under continuous immersion at temperatures up to 110 °C (230 °F).

Belzona 1391T: A ceramic-filled epoxy coating which provides erosion and corrosion resistance to equipment operating under immersion up to 130°C (266°F).

Belzona 5115: A high-gloss top coating designed for the long-term protection of metallic and nonmetallic surfaces against weathering, corrosion, and chemical attack.

Benefits of Using Epoxy Pipeline Coatings

- Cold-applied, no hot work required

- Reduced downtime and maintenance costs

- Chemical, temperature, and abrasion resistance

- Safe and simple application process

- Extended service life of critical assets

Belzona’s range of pipeline coatings ensures long-term protection across diverse industries, including power generation, water treatment, and petrochemical facilities.

Pipeline coatings are not only a protective measure, but they are also a long-term investment in asset reliability and safety. By selecting the right epoxy pipeline coating, facilities can prevent corrosion-related failures, minimize environmental risks, and enhance overall system efficiency.

Frequently Asked Questions

Contact A Belzona Distributor for More About Pipeline Coatings

Digital Content Creator, Belzona Inc., Miami, Florida

Hello,

My name is William van Rijswijk

I am HR Manager by PeSa Personal GmbH

We are looking for pipecoaters

Can you help us out

Hello William, thank you for your comment. For more information about this solution, please use the following link to contact your local Distributor – https://belzona.com/en/about/disfinder.aspx. Best regards, Belzona Team.

Thanks for also talking about how the need for corrosion protection necessitates internal pipe coating. I’m interested in looking for a good service like that because I will be getting one of my commercial properties renovated. Getting ample protection for it will surely require such coatings.