In this post, we will take a look at how to repair pitting corrosion using Belzona’s epoxy solutions. Corrosion is the gradual destruction and degradation of materials through chemical and/or electrochemical reactions with their environment. In the most serious of cases, it can cause buildings and bridges to collapse, oil pipelines to break and chemical plants to leak. There are several different types of corrosion that can occur and, in this blog, we take a look at one specific type pitting corrosion. Metal pitting is a dangerous and extremely costly problem across a wide range of sectors, and this post provides a step-by-step guide on how to rebuild pitting damage effectively as well as some real world case studies that demonstrate pitting repair methods.

What Causes Pitting Corrosion?

Pitting corrosion is a localised form of corrosion that creates small cavities or “pits” in a metal surface. Unlike general corrosion, which affects a larger area more evenly, pitting corrosion often goes unnoticed until significant damage has occurred. Common pitting corrosion causes include chloride contamination, mechanical damage to protective coatings, and areas where water or moisture can collect and remain stagnant.

Many metals, such as stainless steel, rely on a thin passive layer to prevent corrosion. When this protective layer is damaged, stainless steel pitting corrosion can develop, often progressing rapidly beneath the surface. Once initiated, these pits can penetrate deeply into the material, leading to metal pitting that compromises structural integrity and can be costly to repair if left untreated.

How to Repair Pitting Corrosion (Step-By-Step)

Step One: Prepare the Surface

Brush away any loose contamination and clean the area with Belzona 9111 (Cleaner Degreaser) or any other effective cleaner which does not leave a residue. Then, roughen the surface by blast cleaning, deeply scoring, or grinding and clean again.

Step Two: Mix Your Epoxy Metal Repair Paste Belzona 1511 (Super HT-Metal)

Transfer the entire contents of the Belzona 1511 (Super HT-Metal) Base and Solidifier modules onto the Belzona Working Surface. Mix thoroughly together to achieve a uniform material without streakiness.

Step Three: Wet Out the Pitted Area with Epoxy Metal Repair Paste

Use a short bristled brush to carefully wet out the prepared surface with Belzona 1511 (Super HT-Metal). Firmly press down to fill in all cracks, remove entrapped air, and ensure maximum contact with the substrate.

Step Four: Use an Applicator to Finish the Rebuild

Smooth over the pitting repair using the plastic applicator provided. Contour the Belzona 1511 (Super HT-Metal) to the correct profile or allow it to cure, then machine it down. Refer to the Belzona 1511 (Super HT-Metal) Instructions For Use for cure times.

Step Five: Allow Belzona 1511 (Super HT-Metal) to Cure and Prepare for Overcoating

Once cured, depending on service conditions, you may want to add a corrosion-resistant coating. As this example is a high-temperature vessel, a high-temperature lining was selected.

Step Six: Mix Corrosion-Resistant High-Temperature Coating (Belzona 1593)

Begin by combining the entire contents of the Belzona 1593 Solidifier can into the Base module. Mix thoroughly together to achieve a uniform material without streakiness.

Step Seven: Apply Corrosion-Resistant Lining (Belzona 1593)

Apply the Belzona 1593 directly onto the prepared surface with a stiff-bristled brush or the plastic applicator provided. As soon as the first coat is applied, apply a further coat of Belzona 1593 (refer to the Belzona 1593 Instructions For Use for coverage rates and cure times). Afterwards, visually inspect for pinholes and misses and immediately brush out where detected.

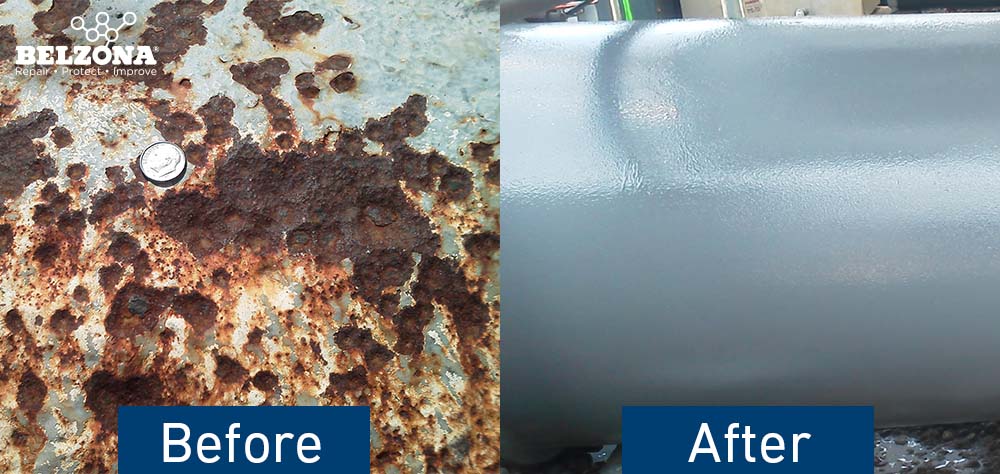

Case Study: Severe Pitting Corrosion at a Petrochemical Plant

At a Petrochemical Plant in Southeast Texas, USA, multiple areas of carbon steel pipework were suffering from heavy corrosion which had resulted in major pitting.

The severity of this pitting had caused the pipe walls to thin in many areas and completely through the wall in one spot, which resulted in a leak.

Firstly, a solution was needed to fix the live leak. A fast-curing epoxy-based metal repair composite Belzona 1211 (Super XL-Metal) was used to fix the live leak. This solution can be used for both permanent and emergency repairs, and cures at room temperature with no hot work involved.

Once the live leak had been sealed, the team moved on to the pitted metal repair using an epoxy-based composite Belzona 1111 (Super Metal). This solution cures at room temperature, so no hot work is involved, and it offers reduced health and safety risks due to being solvent-free.

Find out more about this application, read the case study below:

Case Study: Pitting Corrosion and Bi-Metallic Corrosion in the HVAC Industry

Heat exchangers are commonplace in the Heating, Ventilation and Air Conditioning (HVAC) industry. They work by transferring heat from one place to another. Heat exchangers can be found in many different places, usually working to heat or cool buildings or helping engines and machines to work more efficiently.

In a facility in Ontario, Canada operating in the HVAC Industry, a heat exchanger (HEX) was suffering from pitting corrosion and bi-metallic corrosion, which was resulting in leakage.

An epoxy-based composite for pitted metal repair Belzona 1111 (Super Metal) was applied to the surfaces of the tube sheets and end covers to fill any pitting and damage. Next, a ceramic filled epoxy coating designed to provide erosion and corrosion resistance of metal surfaces Belzona 1321(Ceramic S-Metal), was applied to the surfaces using a brush. These non-metallic composite materials also stop the galvanic corrosion issues commonly seen in heat exchangers. Due to the solution chosen, the application was able to be carried out without the need for specialist tools.

The multipurpose polymeric coating used in this application will protect the heat exchanger from bi-metallic and pitting corrosion, whilst also providing resistance to a wide range of chemicals.

Video: Pitting Corrosion Rebuild on a High Temperature Process Vessel:

Belzona’s epoxy solutions repair corroded metals and can also be used as a preventative measure to protect against future corrosion.

What causes pitting corrosion?

Pitting corrosion causes vary, but common factors include chloride contamination, mechanical damage to protective coatings, and stagnant water collecting on the surface. For example, stainless steel pitting corrosion often begins when its passive layer is damaged, allowing localised attack to penetrate deeply.

How can I carry out stainless steel pitting repair?

Stainless steel pitting repair typically involves removing contamination, cleaning and roughening the surface, then rebuilding the pitted metal with an epoxy composite such as Belzona 1111 (Super Metal). In some cases, additional protective coatings are applied to prevent further damage.

What’s the best method for metal pitting repair?

The best method for metal pitting repair depends on the environment and extent of damage. Epoxy-based solutions are ideal because they can rebuild pitted metal, bond well to prepared surfaces, and provide long-term corrosion resistance.

How to fix pitted metal in industrial equipment?

To fix pitted metal, remove loose corrosion, prepare the surface by grit blasting or grinding, fill the pits with an epoxy repair paste, and overcoat with a corrosion-resistant lining. This method prevents further pitting damage and extends service life.

Learn more

Pipework Metal Loss Repair: Fast and Easy with Belzona 1161

How to Mix Belzona 1151 (Smoothing Metal) for Rebuilding Shallow Pitting

Contact Your Local Distributor to Learn More about Belzona Solutions for Pitting

Content Creator, Belzona Inc., Harrogate, UK.

Responsible for writing a range of content including blog posts, press releases and a range of marketing material.

Good day, I have a consult about this application.

Is posibble to applicate this product in a surface with pittings of one tail shaft of one submarine unity?

Perhaps I wish you response this answer

Best Regards.

Hello Augusto, thank you for your comment. For more information about this solution, please use the following link to contact your local Distributor – https://belzona.com/en/about/disfinder.aspx. Best regards, Belzona Team.