- Introduction

- Surface Preparation Standard Specifiers

- ISO 8501-1 – Surface Preparation Standard

- SSPC-SP 1 – Solvent Cleaning

- SSPC-SP 2 – Hand Tool Cleaning

- SSPC-SP 3 – Power Tool Cleaning

- SSPC-VIS 3

- SSPC-SP 10/NACE 2, Near-White Metal Blast Cleaning

- SSPC-SP 5/NACE No. 1 – White Metal Blast Cleaning

- SSPC-VIS 1

- SSPC-SP 6/NACE No. 3 – Commercial Blast Cleaning

- SSPC-SP 6 WAB/NACE WAB-6, Commercial Wet Blast Cleaning

- SSPC-VIS 5/NACE VIS 9

- SSPC-SP 11, Power Tool Cleaning to Bare Metal

- SSPC-SP WJ/NACE WJ – Waterjet Cleaning of Metals

- SSPC-SP 13/NACE 6, Surface Preparation of Concrete

- SSPC-SP 15 (Commercial Grade Power Tool Cleaning)

- Frequently Asked Questions

Introduction

“When things don’t work as they should, it often means that standards are absent.” – ISO

A great number of reported premature coating failures are related to poor surface preparation practices. This is primarily the reason as to why surface preparation standards are available: to maximize coating life and minimize remedial costs.

The surface preparation standards recommended for Belzona applications are detailed as follows. It is strongly advised that each standard be carefully reviewed prior to commencement of any surface preparation activity.

Surface Preparation Standard Specifiers

The two prevailing surface preparation standards are ISO 8501 and the SSPC/NACE joint standards provided by ISO, NACE International, and SSPC.

ISO – The International Organization for Standardization published ISO 8501 in 1988. ISO 8501 is a pictorial standard and consists of four parts:

- Rust grades and preparation grades of uncoated steel substrates and of steel substrates after overall removal of previous coatings.

- Preparation grades of previously coated steel substrates after localized removal of previous coatings.

- Preparation grades of welds, edges and other areas with surface imperfections.

- Initial surface conditions, preparation grades and flash rust graded in connection with high-pressure water jetting.

SSPC / NACE International – The Society for Protective Coatings and the National Association of Corrosion Engineers produced surface preparation joint standards in 2000. These are text descriptions not pictorial. However, they can be used together with visual guides (VIS). Both specifiers agreed to merge and form a new association on April 21, 2020.

ISO 8501-1 – Surface Preparation Standard

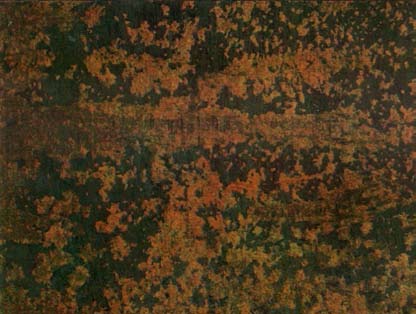

ISO 8501-1 identifies four rust grades commonly found on uncoated steel surfaces, as shown below.

ISO 8501-1 also provides grades of visual cleanliness after the preparation of the uncoated surface.

St 2 – Thorough scraping and wire brushing (Comparable to SSPC-SP 2 & SSPC-SP 3)

Note: Illustrations are only provided for steel rust grades B, C, and D.

St 3 – Very thorough scraping and wire brushing (Comparable to SSPC-SP 2 & SSPC-SP 3)

Sa 1 – Light blast cleaning (Comparable to SSPC-SP 7 /NACE No. 4)

Sa 2 – Thorough blast cleaning (Comparable to SSPC-SP 6 / NACE No. 3)

Sa 2 1/2 – Very thorough blast cleaning (Comparable to SSPC-SP 10 / NACE No. 2)

Sa 3 – Blast cleaning to pure metal (Comparable to SSPC-SP 5 / NACE No. 1)

SSPC-SP 1 – Solvent Cleaning

Solvent cleaning is mostly used for removing all visible oil and grease from steel surfaces prior to any other surface preparation methods.

A solvent-cleaned surface shall be free of visible grease, oils, dirt and dust and drawing and cutting compounds.

Note: When oil and grease are deeply impregnated into the steel surface, other oil removal techniques should be used together with solvent cleaning. Consult Belzona for additional details.

Hint: A simple method of oil and grease detection to be used, if any dispute, consists of drawing a line at medium pressure with a piece of chalk from a clean area through the suspect area onto another clean area. If the line through the suspect area decreases in intensity, but intensity is regained in the second clean area again, the suspected area is contaminated to the extent that degreasing is required.

Recommended method for degreasing surfaces prior to Belzona applications:

- Remove visible oil and grease with a scraper.

- Spray acceptable cleaners onto the surface and wipe with a brush or lint-free rags.

- Allow solvent to evaporate.

- Acceptable cleaners for Belzona applications are those solvents which do not leave residue behind upon vaporization, including methyl ethyl ketone (MEK), acetone, and Belzona 9111.

Note: Please confirm with Belzona prior to use if any other cleaner is available for your application.

SSPC-SP 2 – Hand Tool Cleaning

Hand tool cleaning is a method of preparing steel surfaces by the use of nonpowered hand tools such as wire brushes, scrapers, chisels, knives, and chipping hammers among others. It is mostly used when power-operated equipment is unavailable, where the work is inaccessible to power tools, or where the application is too small to warrant use of powered tools.

When viewed without magnification and used in conjunction with SSPC-SP 1, the hand-tool prepared surface shall be free from loose mill scale, rust, paint, grease, oils, oxide film and dirt and dust.

Note: This standard can be used in conjunction with SSPC-VIS 3 as a photographic guide or reference of the finished substrate.

Comparable standard: ISO 8501-1, St 2 or St 3

Recommended method for Belzona applications:

- Degrease surface with acceptable cleaners [SSPC-SP 1].

- Use a dull putty knife to lift mill scale, rust or existing coating/paint from the substrate.

- Remove all loose mill scale, rust, or coating using hand tools.

- Remove any debris by using a vacuum or by blowing dry compressed air.

Note: Surface mill scale, rust, and coating are considered loose (or not tightly adhered) if they can be removed by lifting with a dull putty knife.

Note: Bear in mind that although hand tool cleaning may be acceptable for certain external Belzona applications, this technique is insufficient to provide acceptable surface cleanliness for immersion service. Hence, it is not recommended by Belzona for such applications.

SSPC-SP 3 – Power Tool Cleaning

Power tool cleaning is a method of preparing steel surfaces by the use of powered hand tools such as grinders, rotary wire brushes, scalers, sanders, and flap wheels among others.

When viewed without magnification and used in conjunction with SSPC-SP 1, the powered tool prepared surface shall be free from loose mill scale, rust, paint, grease, oils, oxide film and dirt and dust.

Note: SSPC-SP 3 differs from SSPC-SP 11 (below) in that it only requires removal of loosely adhered material and does not require producing or retaining a surface profile.

Note: This standard can be used in conjunction with SSPC-VIS 3 as a photographic guide or reference of the finished substrate.

Comparable standard: ISO 8501-1, St 2 or St 3

Recommended method for Belzona applications:

- Degrease surface with acceptable cleaners [SSPC-SP 1].

- Use a dull putty knife to lift mill scale, rust or existing coating/paint from the substrate.

- Remove all loose mill scale, rust, or coating using powered tools.

- Remove any debris by using vacuum or by blowing dry compressed air.

Note: Bear in mind that although power tool cleaning may be acceptable for certain external Belzona applications, this technique is insufficient to provide acceptable surface cleanliness for immersion service. Hence, it is not recommended by Belzona for such applications.

SSPC-VIS 3

SSPC-SP 10/NACE 2, Near-White Metal Blast Cleaning

This joint standard covers the requirements for near-white metal blast cleaning of uncoated or coated steel surfaces by the use of abrasives.

When viewed without magnification and used in conjunction with SSPC-SP 1, the near-white metal blasted surface shall be free of mill scale, rust, paint, grease, oils, oxide film, dirt and dust.

However, up to 5% light staining (light shadows, streaks or discolorations) per unit of area is allowed, i.e. , a square of dimensions 3.0 in. x 3.0 in. (76 mm x 76 mm).

Note: This standard can be used in conjunction with SSPC-VIS 1 as a photographic guide or reference of the finished substrate.

Comparable standard: ISO 8501-1, Sa 2 1/2

Note: Near-white metal blast cleaning is the recommended surface cleanliness standard for most Belzona applications.

Note: The abrasive used for Belzona applications shall comply with SSPC-AB1 and chosen of Class A [crystalline silica less than or equal to 1.0%] and Grade 4 [abrasives which produce surface profiles of 3.0 to 3.5 mils (75 to 127 micrometers) when tested in accordance with surface profilers.

SSPC-SP 5/NACE No. 1 – White Metal Blast Cleaning

This joint standard covers the requirements for white metal blast cleaning of uncoated or coated steel surfaces by the use of abrasives.

When viewed without magnification and used in conjunction with SSPC-SP 1, the white metal blasted surface shall be uniformly free of of mill scale, rust, paint, grease, oils, oxide film, dirt and dust.

Note: White Metal blast cleaning condition is accepted yet not required for Belzona applications.

Note: This standard can be used in conjunction with SSPC-VIS 1 as a photographic guide or reference of the finished substrate.

Comparable standard: ISO 8501-1, Sa 3

SSPC-VIS 1

VIS 1 provides reference photographs of previously coated and uncoated surfaces before and after dry abrasive blast cleaning.

SSPC-SP 6/NACE No. 3 – Commercial Blast Cleaning

This joint standard covers the requirements for commercial blast cleaning of uncoated or coated steel surfaces by the use of abrasives.

When viewed without magnification and used in conjunction with SSPC-SP 1, the commercial blasted surface shall free of of mill scale, rust, paint, grease, oils, oxide film, dirt and dust.

However, up to 33% light staining (light shadows, streaks or discolorations) per unit of area is allowed, i.e. , a square of dimensions 3.0 in. x 3.0 in. (76 mm x 76 mm).

Note: This is an acceptable cleanliness technique for several Belzona products such as Belzona 1161, Belzona 1251, Belzona 5831, Belzona 5841, and Belzona 5851.

Note: This standard can be used in conjunction with SSPC-VIS 1 as a photographic guide or reference of the finished substrate.

Comparable standard: ISO 8501-1, Sa 2

SSPC-SP 6 WAB/NACE WAB-6, Commercial Wet Blast Cleaning

This joint standard covers the requirements for commercial wet blast (WBC) cleaning of uncoated or coated steel surfaces by using a mixture of water and abrasives.

When viewed without magnification and in conjunction with SSPC-SP 1, the commercial wet blasted surface shall free of of mill scale, rust, paint, grease, oils, oxide film, dirt and dust.

However, up to 33% light staining (light shadows, streaks or discolorations) per unit of area is allowed, i.e. , a square of dimensions 3.0 in. x 3.0 in. (76 mm x 76 mm).

Note: This is an acceptable cleanliness technique for Belzona products such as Belzona 1251 and Belzona 5851.

Note: This standard can be used in conjunction with SSPC-VIS 5/NACE VIS 9 as a photographic guide or reference of the finished substrate.

SSPC-VIS 5/NACE VIS 9

SSPC-VIS 5/NACE VIS 9 provides reference photographs of previously coated and uncoated surfaces before and after wet abrasive blast cleaning.

SSPC-SP 11, Power Tool Cleaning to Bare Metal

This specification covers the requirements for power tool cleaning to produce a bare metal surface and to retain or produce a surface profile of at least 1 mil (25 micrometer), when measured with surface profilers.

When viewed without magnification and used in conjunction with SSPC-SP 1, the power-tool cleaned-to-bare-metal surface shall be free of mill scale, rust, paint, grease, oils, oxide film, dirt and dust.

Note: SSPC-SP 11 differs from SSPC-SP 3 in that it requires removal of both loose and tightly adhered materials and requires producing or retaining a surface profile. SSPC-SP 11 also differs from SSPC-SP 15 in that it does not allow staining on the surface.

Note: This is an acceptable cleanliness technique for several Belzona products such as Belzona 1161, Belzona 1212, and Belzona 5831.

Note: This standard can be used in conjunction with SSPC-VIS 3 as a photographic guide or reference of the finished substrate.

SSPC-SP WJ/NACE WJ – Waterjet Cleaning of Metals

Waterjetting (WJ) uses pressurized water discharged from a nozzle at pressures of 70,000 psig (70 MPa) or greater to prepare a surface for coating or inspection. WJ does not produce a profile. Rather, it exposes the original profile if one existed.

There are four standards in SSPC-SP WJ/NACE WJ:

- SSPC-SP WJ-1/NACE WJ-1, Waterjetting to Bare Substrate

- SSPC-SP WJ-2/NACE WJ-2, Very Thorough Waterjetting

- SSPC-SP WJ-3/NACE WJ-3, Thorough Waterjetting

- SSPC-SP WJ-4/NACE WJ-4, Light Waterjetting

Note: These four standards can be used in conjunction with SSPC-VIS 4/NACE VIS 7 for visual representations of a surface before and after waterjetting.

Waterjetting is also classified depending on the pressures at which water is discharged:

- High-Pressure Waterjetting (HP WJ): waterjetting at pressures from 10,000 to 30,000 psig (700 – 2,100 bar)

- Ultrahigh-Pressure Waterjetting (UHP WJ): waterjetting at pressures above 30,000 psig (2,100 bar)

Note: UHP WJ is an acceptable cleanliness technique for Belzona 1161 and Belzona 5831.

SSPC-SP 13/NACE 6, Surface Preparation of Concrete

This joint standard covers the requirements for surface preparation of concrete by different means prior to the application of bonded protective coatings or lining systems.

An acceptable prepared concrete surface should be free of contaminants, laitance, loosely adhering concrete and dust, and should be sound.

Note: For Belzona applications on concrete, the concrete surface shall be allowed to cure for a minimum of 28 days (if new) or until its moisture content is below 6% (when using a Protimeter) or less than 3 lb/24 hr/1,000 ft2 (15 g/24 hr/m2) when testing in accordance with ASTM F1869.

Compatible standard: ICRI (International Concrete Repair Institute) – Technical Guidelines 310.2R 2013 – Selecting and Specifying Concrete Surface Preparation for Sealers, Coatings, Polymer Overlays, and Concrete Repair

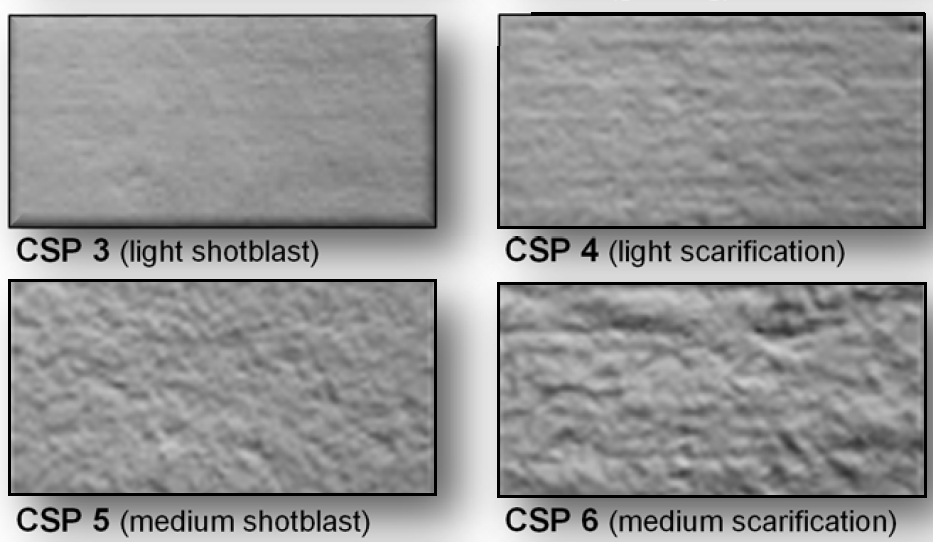

Note: If Technical Guidelines 310.2R is used, the profile of the concrete surface for Belzona applications should be at least CSP 3. Refer to photos below.

SSPC-SP 15 (Commercial Grade Power Tool Cleaning)

This specification covers the requirements for power tool cleaning to produce a commercial grade power-tool cleaned surface and to retain or produce a surface profile of at least 1 mil (25 micrometer), when measured with surface profilers.

When viewed without magnification and used in conjunction with SSPC-SP 1, the power-tool commercial grade cleaned surface shall be free of of mill scale, rust, paint, grease, oils, oxide film, dirt and dust.

However, up to 33% light staining (light shadows, streaks or discolorations) per unit of area is allowed, i.e. , a square of dimensions 3.0 in. x 3.0 in. (76 mm x 76 mm).

Note: SSPC-SP 15 differs from SSPC-SP 3 in that it requires removal of both loose and tightly adhered materials and requires producing or retaining a surface profile. SSPC-SP 15 also differs from SSPC-SP 11 in that it allows for random staining on the surface.

Note: This is an acceptable cleanliness technique for several Belzona products such as Belzona 1251, Belzona 5841, and Belzona 5851.

Note: This standard can be used in conjunction with SSPC-VIS 3 as a photographic guide or reference of the finished substrate.

Frequently Asked Questions

What is surface preparation?

Surface preparation refers to the process of cleaning, treating, or profiling a substrate (such as metal, concrete, or plastic) before applying a protective coating or repair material. This crucial step removes contaminants and creates a suitable surface profile to ensure proper adhesion of the new system.

Without proper surface preparation, even the most advanced coatings will fail to bond correctly, leading to premature system failure, reduced performance, and costly repairs.

The most commonly accepted standards for surface preparation come from the NACE International/Society for Protective Coatings (SSPC), which have recently merged to form AMPP – The Association for Materials Protection and Performance. These joint standards cover a wide range of surface preparation methods, from hand and power tool cleaning to abrasive blasting and water jetting.

In addition, the International Organization for Standardization (ISO) provides globally recognized standards such as ISO 8501, which defines visual grades of rust and preparation cleanliness. Adhering to these standards ensures consistency, quality, and durability in protective coating systems.

Why is surface preparation important before coating?

Coatings and repair materials rely on a strong bond with the underlying surface and that bond is only as good as the surface it’s applied to. Without proper preparation, contaminants like rust, oil, or loose material can prevent adhesion, causing the system to delaminate, blister, or fail prematurely.

Surface preparation doesn’t just clean; it also creates a physical anchor pattern or profile that helps the coating mechanically grip the substrate. Think of it like painting a smooth glass window versus a sanded piece of wood — the rougher, cleaner surface provides a better key. Skipping this step is one of the most common reasons for coating failure.

What surface preparation is recommended for concrete

Concrete presents a different challenge than steel due to its porosity and surface laitance (a weak, dusty layer that forms during curing). Surface preparation for concrete typically involves mechanical abrasion such as grinding, scarifying, or shot blasting to expose sound, clean concrete and open up the pores for coating penetration.

It’s essential to remove oil, grease, curing compounds, or any contaminants that could block adhesion. Moisture testing is also critical, as some coatings require dry substrates while others can tolerate damp surfaces. The result should be a roughened, clean surface free from dust and weak material.

What surface preparation is recommended for steel?

Steel requires surface preparation that removes corrosion products, old coatings, and mill scale, while creating a profile for the coating to anchor onto. The most effective and widely recommended method is abrasive blasting to a minimum of Sa 2.5, especially when long-term corrosion protection is critical.

For less critical applications or when blasting isn’t possible, power tool cleaning (e.g., SSPC-SP11) may be used, but it provides a lower profile and reduced cleanliness. The chosen method should always be matched to the service conditions and coating system to ensure performance.

What is the ISO 8501 standard?

ISO 8501 is an international standard that provides a visual guide and written descriptions for assessing the cleanliness of steel surfaces prior to coating. It includes grades of rust (A to D) and levels of preparation (e.g., Sa 2, Sa 2.5, Sa 3), allowing consistent communication between asset owners, contractors, and inspectors.

Rather than being a method itself, ISO 8501 complements surface prep methods by defining how clean a surface should look after treatment. It’s particularly valuable on site, where inspectors use visual comparators to ensure the prep meets specification before coating begins.

What is the SA 2.5 standard?

This is a very thorough blast cleaning (Comparable to SSPC-SP 10 / NACE No. 2).

Sa 2.5 is a surface preparation standard that refers to “near-white metal blast cleaning”. It’s used to describe a level of cleanliness achieved by abrasive blasting steel surfaces. Under this standard, the surface should be free from visible oil, grease, dirt, rust, mill scale, old paint, and other contaminants — with at least 95% of the surface appearing as clean, bright metal.

This level of preparation is commonly specified for high-performance coating systems, especially in aggressive environments like offshore, petrochemical, or marine. Sa 2.5 ensures a sharp, angular surface profile that promotes optimal mechanical adhesion of the coating.

Contact Belzona to Find the Right Surface Preparation for Your Application

Having joined Belzona in 2010, Ian Wade has cultivated a deep expertise in corrosion, coatings, and inspection services. Currently serving as the Technical Services Manager at Belzona’s headquarters in Harrogate, Ian has held various roles. These include Technical Services Engineer and Training Facility Team Leader, where he managed the day-to-day operations of the training facility and collaborated closely with technical and business development teams.

Ian’s professional journey has taken him across the UK and international waters, including stints in South Korea, China, the North Sea, and the Caspian Sea, performing both supervisory and hands-on inspection work. His practical experience extends to on-site applications using Graco spray pumps and hand-applied coatings, directly enhancing operational standards and safety.

Ian is an AMPP (NACE) Certified Coating Inspector Level 2 and is currently advancing his knowledge by pursuing a Bachelor of Engineering in Mechanical Engineering part-time at The Open University, expected to complete in 2027. He has written a number of technical articles including: Strengthening the Bond with Reliable Structural Adhesives and The Benefits of Protecting Storage Tanks with Sprayable, Polymeric Coatings. His commitment to technical excellence and his robust experience make him a valued leader and innovator in his field.