- Video: How to Fix a Failing Concrete Expansion Joint with Belzona

- Why Expansion Joints Fail and How to Fix Them

- Belzona Solution Polyurethane Sealants for Expansion Joint Repairs

- Step-by-Step Guide: How to Repair a Concrete Expansion Joint Using a Polyurethane Sealant

- Conclusion: Ensure Long-Term Protection for Concrete Expansion Joints

- Frequently Asked Questions

- Learn More

Video: How to Fix a Failing Concrete Expansion Joint with Belzona

Why Expansion Joints Fail and How to Fix Them

Concrete expansion joint sealants play a crucial role in bridges, highways, and industrial concrete floors by allowing controlled movement and preventing cracks caused by temperature fluctuations and structural shifts.

An expansion joint is a mid-structure separation designed to absorb vibration, join objects, or allow movement. In structures, expansion joints can help absorb the expansion and contraction of concrete slabs as a result of temperature changes. Without a durable expansion joint, the concrete can crack or distort.

However, over time, concrete expansion joints can fail due to:

❌ Incompressible debris restricting movement, leading to concrete spalling.

❌ Water ingress, which weakens the joint and surrounding structure.

❌ Sealant failure, either through adhesion loss (detachment from joint walls) or cohesion loss (tears within the sealant itself).

To prevent these issues, polyurethane expansion joint sealants provide flexibility, durability, and resistance to environmental wear, ensuring long-term joint protection.

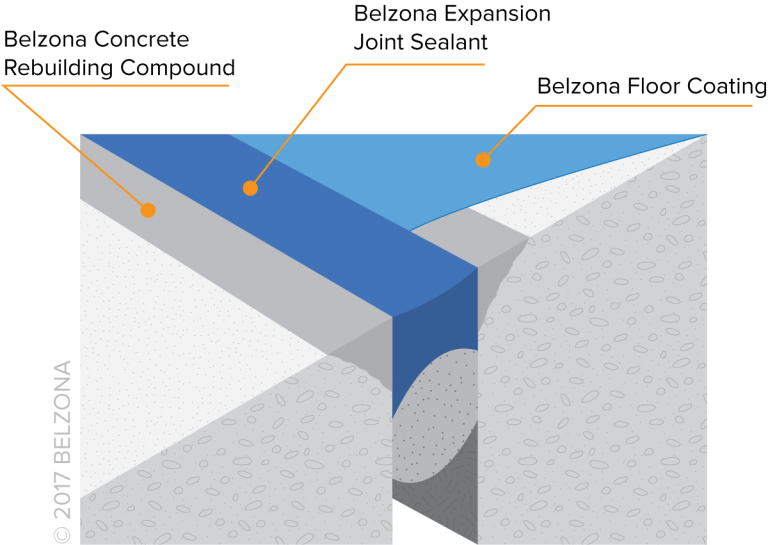

Belzona Solution Polyurethane Sealants for Expansion Joint Repairs

Conventional expansion joint seals such as strip seals and compression seals have their own individual disadvantages and common failures. Belzona provides polyurethane sealants that protect expansion joints from incompressible debris while offering advantageous mechanical properties including high movement capability, high elastic recovery, and high abrasion resistance. In addition, Belzona polyurethane sealants contain low odours and adhere well to a range of substrates.

Step-by-Step Guide: How to Repair a Concrete Expansion Joint Using a Polyurethane Sealant

For this repair, we used Belzona’s polyurethane sealant systems, designed to provide long-lasting flexibility and adhesion. For this repair, we used:

- Belzona 4111 (Magma-Quartz) and a wooden batten to reform the nosings of the joint

- Belzona 2221 (MP Fluid Elastomer) and a backer rod to create a new joint sealant

- Belzona 5231 (SG Laminate) to provide protection of the expansion joint and an aesthetic look

Additionally, we utilized Belzona 9111 (Cleaner/Degreaser) to clean the substrate, Belzona 9411 (Release Agent) to be applied to the wooden batten, a handheld grinder and a pole sander to prepare the substrate, and a mixer for preparing Belzona 4111 (Magma-Quartz)

- Remove all Existing material

Using a grinder with a round disc, remove all damaged sealant and vee out the edges of the nosings.

- Remove all Debris

Vacuum all the debris and dust.

- Roughen the Surface

Abrade the edges and the surface with a pole sander.

- Clean the Surface

Thoroughly clean the surface with a cleaner/degreaser.

- Condition the Repair Surface

Thoroughly mix Belzona 4911 (Magma TX Conditioner) and brush it over the entire repair area.

- Insert Wooden Batten

Apply Belzona 9411 (Release Agent) onto the wooden batten and position it in the joint.

- Mix Belzona 4111 (Magma-Quartz)

Thoroughly mix Belzona 4151(Magma-Quartz Resin) Base and Solidifier until a homogeneous mix is achieved. Slowly add Belzona 4111 (Magma-Quartz) Aggregate into the mix until the desired consistency is obtained.

- Trowel mixed Belzona 4111 (Magma-Quartz)

Trowel mixed Belzona 4111 (Magma-Quartz) up to the former to rebuild the expansion joint nosings. Make sure to fill in all the empty spaces with the mixed product.

- Press Down Firmly

Pack Belzona product down firmly to avoid air pockets formation.

- Remove the Batten

Once the Belzona product has cured, carefully remove the wooden former from the joint.

- Insert Backer Rod

Insert pre-measured foam backer rod into the joint.

- Condition the Joint

Using Belzona 2911, condition the internal parts of the joint.

- Fill the Joint with Belzona 2221 (MP Fluid Elastomer)

Pour mixed Belzona 2221 (MP Fluid Elastomer) to fill the joint.

- Smooth Out

Smooth out the surface, leaving it slightly concave.

- Mix Belzona 5231 (SG Laminate)

Thoroughly mix Belzona 5231 (SG Laminate) Base and Solidifier until a uniform color is achieved.

- Apply mixed Belzona 5231 (SG Laminate)

Using a conventional paint roller, apply mixed Belzona 5231 (SG Laminate) over the expansion joint repair area.

- Application Complete

Remove all tape masking the joint and the repair area. The application is now complete!

Conclusion: Ensure Long-Term Protection for Concrete Expansion Joints

Using the right polyurethane sealant for expansion joint repair ensures long-term durability, flexibility, and protection against external factors like moisture, traffic, and debris buildup.

Frequently Asked Questions

Why Use Polyurethane Sealant for Expansion Joint Repairs?

By using Belzona polyurethane sealants, industrial facilities benefit from:

✅ High movement capability – Absorbs expansion and contraction stress.

✅ Superior elastic recovery – Maintains flexibility and adhesion over time.

✅ Abrasion and weather resistance – Withstands heavy traffic and environmental exposure.

✅ Long-lasting durability – Reduces maintenance costs and repair frequency.

Why are Expansion Joint Repairs Necessary?

Seals commonly fail due to adhesion loss and cohesion loss. Adhesion loss is evident when detachment of the seal from joint walls occurs. Adhesion loss is the loss of bond between the sealant and joint walls. Cohesion loss is evident when a tear on or in the seal occurs. Cohesion loss is the loss of internal bond in the sealant.

What are Conventional Expansion Joint Seals?

Two types of common seals are strip seals and compression seals:

Strip seals are flexible neoprene membranes adhered to the joint walls. They adhere well and prevent water ingress, but the seals can tear and disjoin under traffic if incompressible debris settles on top.

Compression seals are neoprene or cellular seals in the form of a series of webs that provide outward pressure against joint walls to hold the seal in place. They are ready for use out of manufacturing, meaning no mixing or curing is necessary. The seals need to be correctly sized to maintain the pressure against the walls, but the seal can still disjoin with the loss of elasticity over time.

What are Expansion Joints Made of?

Expansion joints are usually made from metal, rubber or braided.

Learn More

In this guide, we demonstrate a concrete expansion joint repair that can apply to any industry and any type of concrete joint. For hospitals we have a method of expansion joint repair method called “Smooth Ride” – learn more here: In Action: Repairing Failed Expansion Joints in Healthcare

Learn more about the properties and performance testing of Belzona Elastomers

Contact Your Local Distributor to Learn More About Belzona Solutions for Expansion Joints

Yulia Burova, Marketing Director, Belzona Inc., Miami FL, USA

Hi, In order to resist 98% sulfuric acid, we need a kind of vinyl ester resin that is resistant to the corrosiveness of this acid.

I did not find such a product in Hetron and Sancor products

If you have such a product in Belzona products? which is 98% resistant to sulfuric acid

Please introduce Belzona with complete analysis and technical data

Hello Keyvan,

For detailed information about Belzona’s products, including chemical resistance, please contact your local Distributor here: https://www.belzona.com/en/about/disfinder.aspx. They will be able to provide you with the best solution to suit your needs.

Thank you.

Yulia, your post here is fantastic, and it will prove to be valuable for me. Now, I can fix a failing expansion joint quickly, and that’s what I’ve wanted to do for a long time.

Your blog is very informative! It will help those who don’t know how to do expansion joint repair because in your videos you have explained each and every step in detail. One who is doing repair work can take help of this blog.

how can we fix a failed strip seal joint.how can I send you a picture please reply me with reason of failure and its repair

Hello

I’m Kishore from India, I am working in a project where we build house with precast technology and as a result after erection of elements provided with grout , we are facing seepage issue in expansion joint. Can you help me out to fit!

Dear Kishore,

Thank you for reading our blog!

Please feel free to contact Belzona representative in India so that you could discuss the issues with expansion joints with someone locally.

Here is the company’s contact information.

Nicco Engineering Services Ltd

2, Hare Street, Nicco House

Kolkata, West Bengal, 700001, India

Telephone:+91 33 66285209

Fax:+91-33-2243 0782

Best regards,

Belzona Team

Pingback: How to Create a New Gasket with Belzona - Belzona Blog

Thank you Yulia Burova,

I am new with Belzona California, and currently working on a client to do expansion joint repair in 62 warehouse location.

Dear Mr. Cartier,

Thank you for your comment and reading the Belzona Blog.

Best regards,

Belzona Team