Beer-making is a tedious process; therefore, people developed specialized machines to make the process easier and more efficient. Thus, people established breweries and the brewing industry was born.

How To Make Beer

Firstly, the beer-making process begins with a Malt mill breaking open the grains. This releases their enzymes. Secondly, a Mash Tun mixes the grains with hot water with rotating arms. The step allows the grain’s starches to turn into fermentable sugars. Further, a vessel called the Lauter Tun purifies the mixture. The vessel continuously adds hot water and agitates the mixture filtering organic material and making it lighter. At this step, the mixture is called wort.

Then, a boiler or kettle boils the filtered wort with hops. Hop is a plant that adds the desired bitterness and flavor to beer. Other flavoring ingredients are also added during this stage. This is the stage where important characteristics of the beer develop such as flavor, color, and aroma. However, not everyone in the brewing industry has a Lauter Tun or boiler, sometimes the Mash Tun also serves their function. Afterward, a Whirlpool tank removes solid settlements from the wort. A heat exchanger quickly cools the wort so that the hot liquid does not kill the yeast. Then, a fermentation tank stores the wort with yeast, allowing it to ferment and turn into beer. Finally, the beer is ready to be bottled and distributed.

Function of Belzona Products

Despite the streamlined process, it does come with difficulties. For instance, the product is sensitive to temperature and oxygen. High temperatures can kill the live yeast while oxygen can spoil and cloud beer, ruining the flavor and clarity. The equipment is also prone to difficulties. Beer creates an acidic environment which as a result can corrode the equipment and surrounding area. Corrosion can also stem from the moisture and fermentation byproducts found during the brewing process. Similarly, the assets in breweries are susceptible to abrasion and erosion. The grains, solid sediments, and even the liquids can erode assets.

However, these are not things to worry about. Belzona dedicates itself to making epoxy repair systems for common industrial problems such as corrosion, erosion, and abrasion. They have been engineered to endure immersion under fluids, including acidic fluids. In addition, some of the products have been certified as food and drinking-water safe. Lastly, the solvent-free products have gone through in-situ tests that determine the products do not change the composition of the final beer product, maintaining the desired flavor, color, and aroma. However, yeast is extremely sensitive to its environment and any change to the pH or medium can alter the production of alcohol. Nevertheless, the presence of Belzona products does not alter the alcohol yield and is deemed acceptable.

The following is a list of Belzona’s series of products that can repair and protect the machinery and equipment found in breweries.

What Belzona 1000 Series can do for Breweries

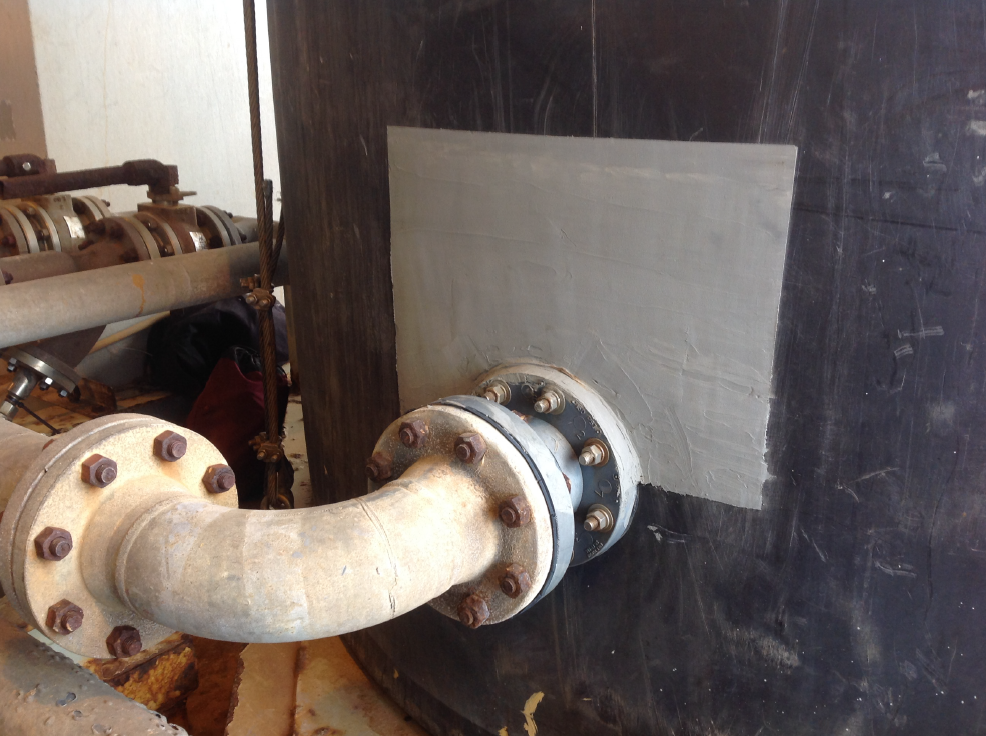

The Belzona 1000 Series is comprised of epoxy-based metal repair composite products. It is a durable and multipurpose series since it can adhere to most metallic surfaces. Furthermore, certain products can be applied over wet conditions even as far as being applied under immersion and enduring immersion at different temperatures. Also, the series was engineered to resist corrosion, erosion, and abrasion. For example, many of the products can resist high concentrations of acids and alkalis allowing for metal equipment to be safeguarded from chemical attack and corrosion.

In addition, ceramic additives can be added to specific products to increase their abrasion and erosion resistance leaving equipment unaffected by highly abrasive material. Finally, individual products were designed to be fast curing for emergency repairs, heat resistant, grip systems, and hydrophobic technology for increased efficiency. The hydrophobic technology repels process fluids and reduces turbulent flow while providing a corrosion-resistant coating. A noticeable property of the energy-efficient Belzona products is that they are also resistant to alcohol.

Likewise, there are NSF potable-water approved solvent-free products which have been proven to not change the composition of the material in contact with Belzona. In addition, the Belzona 1000 Series has been tested and certified by breweries in the past confirming that some products do not influence the flavor of the beer they produce.

Machinery or equipment that may benefit from Belzona 1000 Series include:

| •Bottle Filling Machine | •Malt mill or Grinder |

| •Water Treatment Equipment | •Warehouse Drains |

| •Fermenters | •Storage Tanks |

| •Mash Tun | •Lauter Tun |

| •Heat Exchanger | •Boiler or Kettle |

| •Pipes | •Pumps |

What Belzona 3000 Series can do for the Brewing Industry

The Belzona 3000 Series has waterproofing and weatherproofing properties. Therefore, this series is excellent for protecting roofs and roof protrusions such as skylights, chimneys, and vents from the natural elements. Moreover, within this series, there are fire retardant systems suitable for pipes, ducting, flange covers, storage tanks, and heat exchangers. They can also serve as a leak repair method for more than roofs, but also flanges, connectors, and other pipe elements.

Machinery or equipment that may benefit from Belzona 3000 Series include:

| •Roof | •Vents |

| •Chimneys | •Outside Tanks |

| •Outside Utility Equipment | •Pipelines |

| •Heat Exchangers | •Storage Tanks |

| •Fluids Handling Equipment |

What Belzona 4000 Series can do for Breweries

Concrete is susceptible to corrosion, erosion, and abrasion, but there is a solution: Belzona 4000 Series can repair and protect concrete. For example, this product series can resurface concrete of varying application area sizes and orientations, vertical or horizontal. Also, the series offers chemical and physical resistances, withstanding high chemical concentrations and impacts.

In contrast, concrete does not have the same resistances as the 4000 Series. Impact and chemicals can easily damage concrete; however, the 4000 Series has a much longer service life. Additionally, Belzona 4000 Series cures faster than traditional concrete. The product is ready for operations in just a few hours compared to concrete which cures in 28 days.

Machinery or equipment that may benefit from Belzona 4000 Series include:

| •Warehouse Walls | •Warehouse Floor |

| •Containment Areas | •Bund Areas |

What Belzona 5000 Series can do for the Brewing Industry

Standout products within Belzona 5000 Series are chemical-resistant epoxy-based products suitable for immersion and food-safe products. These products have gone through tests and certifications that verify their safety. Also, a subseries of products provide thermal insulation against corrosion designed for pipework, ducting, and industrial equipment. Finally, some products are used to maintain the facility in order to protect exterior masonry work and provide a grip system for flooring.

Machinery or equipment that may benefit from Belzona 5000 Series include:

| •Interior Lining of Tanks | •Water Treatment Equipment |

| •Warehouse Floors | •Exterior Masonry Work |

| •Pipelines | •Ducting |

| •Storage Tanks | •Exterior Walls and Structure |

| •Process Equipment | •Bund Areas |

| •Pumps | •Submersible Equipment |

Interested in purchasing Belzona’s repair composites and protective coatings?

Digital Content Creator, Belzona Inc., Miami, Florida