Airport Facilities Maintenance

Airport facilities maintenance represent a real challenge due to their diverse nature and broad scope. The airport is a processing facility for passengers, baggage and freight. Additionally, every airport acts as a service facility to aircraft and airlines. An airport comprises infrastructure, facilities, equipment, systems and personnel. All of the components of an airport operation aim to create a satisfactory customer experience.

The efficiency of the airport facilities maintenance has a significant impact on airport performance, as it impacts safety, financial performance, user and passenger satisfaction.

For decades, Belzona has been providing airport facilities maintenance crews with a wide range of repair and maintenance solutions. that require minimal downtime, promote safety and ensure longevity in service. Belzona polymeric materials for airport facilities maintenance have a proven record in assisting airports in various areas: airside, landside and auxiliary systems (power generation, wastewater management, waste management). In this post, we discuss the most typical maintenance issues that airport facilities maintenance crews may experience. And, we demonstrate which of the Belzona polymeric solutions help airports tackle their repair and maintenance situations with success.

Airport Facilities Maintenance Areas

RUNWAYS, TAXIWAYS, APRON

On the airside of the airport facilities maintenance, concrete suffers the most damage. In our previous post “Concrete Solutions From Floor to Ceiling” we talked about the most common causes of concrete damage: freeze-thaw cycles, shrinkage, carbonation, abrasion. Airport facilities are not foreign to that. Temperature fluctuations, seasonality, fuels spillage and de-icing chemicals, heavy traffic load and physical impact during landing contribute to concrete damage.

Repairing a runway and a taxiway is not an easy task. Any downtime caused by repairs may result in flight delays, potential loss of revenue, and unsatisfactory Customer experience. Airports look for durable and long-lasting materials, that do not require lengthy shutdowns or closures to be installed.

Belzona Solutions for Runway, Taxiway, and Apron

Belzona 4000 and 5000 paste-grade and fluid-grade materials are designed for the concrete restoration, leveling and protection on concrete runways, taxiways, aprons, Precision Approach Path Indicators (PAPI) concrete bases, internal floor coatings in aircraft hangars. These materials can potentially be used to assist with concrete repairs and protection in these areas of the airport facilities.

Examples of Belzona Concrete Repairs:

PAPI, LIGHT STANDS, HANGARS

Erosion-corrosion, weathering, physical impact and movement cause damage to the buildings and structures on the airside of an airport. The main areas of concern in facilities are walls, roofs and external/internal floors including expansion joints. Metal structures suffered from corrosion might cause failure to some of the most vital equipment like PAPI, lights, and stands. Like with the runways, repairs on any other structures on the airside need to be done in a timely manner with minimal disturbance to the air traffic.

Belzona Solutions for Airside Facilities and Metal Structures

Belzona 1000 series 100% solids paste-grade and fluid-grade materials may be used for the metal rebuild and erosion-corrosion protection of the lighting structures, PAPI, and aircraft stands. Belzona 4000 series paste-grade materials may be the solution for the concrete restoration of the bases of the lighting poles, PAPI, and stands. Additionally, Belzona 5000/6000 series fluid-grade materials may be considered for the corrosion protection of external metal and concrete surfaces, especially where UV resistance is required.

Examples of Belzona Repairs at Airside:

INTERNAL AND EXTERNAL WALLS

Depending on the airport geographical location, the airport facilities structural integrity might be compromised by a number of factors. Typically, deterioration of concrete, stonework, and construction joints failure is caused by weather, erosion-corrosion, chemical attack, physical impact, and structural movement. Weatherproofing and waterproofing of external walls, repair or replacement of construction joints, concrete restoration and reinforcement are some of the methods that help preserve the walls and structural integrity.

Belzona Solutions for Internal and External Walls

Belzona 2000, 4000 and 5000 series paste-grade and fluid-grade materials may be used for waterproofing, concrete and stonework rebuilding and protection of the external and internal walls, and for the repair, replacement or installation of construction joints.

Examples of Belzona Applications on Walls:

ROOFS AND ROOFING ELEMENTS

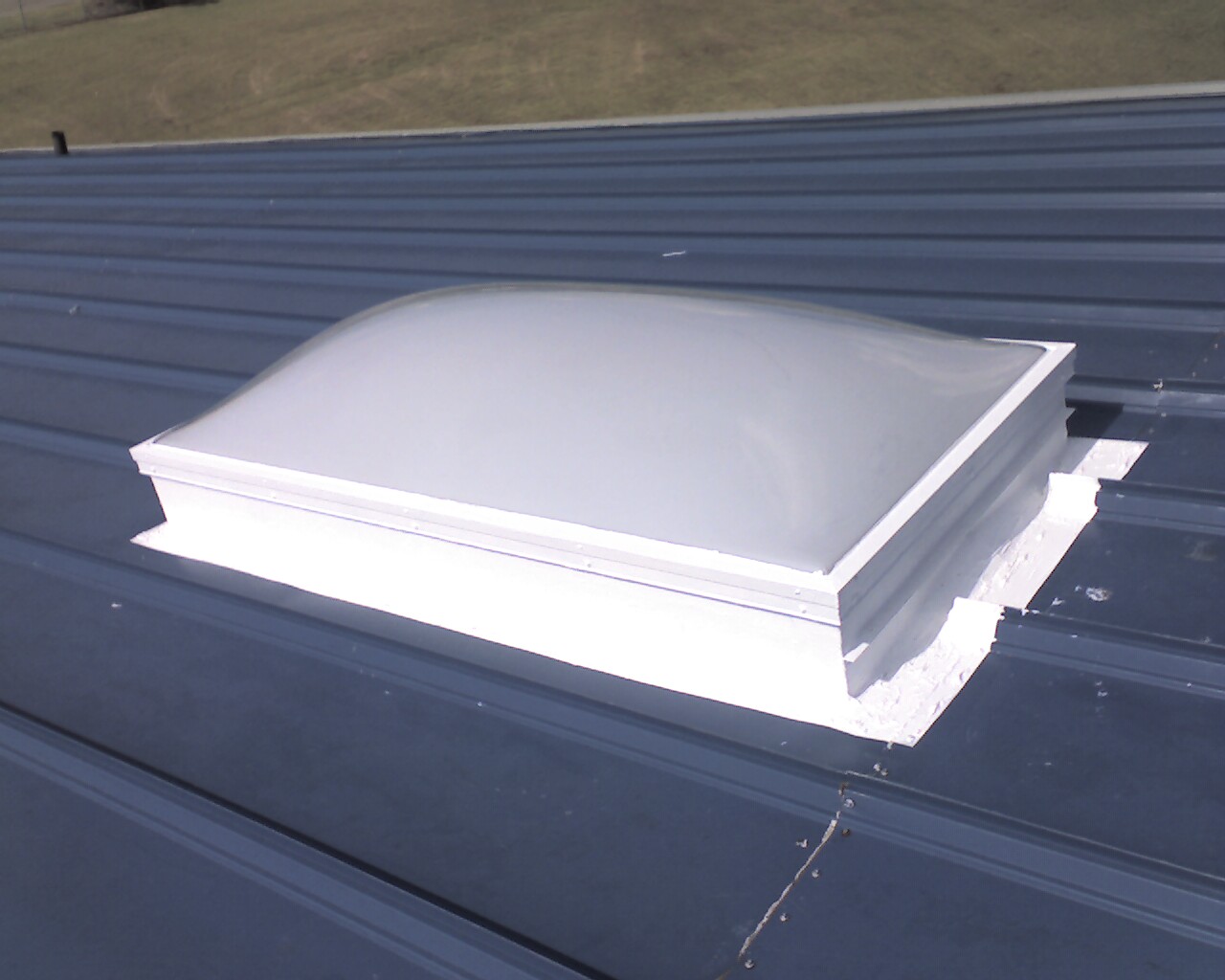

Weathering and/or physical damage to roofs and roof parts: joints, seams, edges, glazing sections, gutters, flashings, skylights, parapet walls and copings, pipes and pipe supports. The damage is typically caused by weather and freeze-thaw cycles, failure of roof materials, substrate movement or impact.

Belzona Solutions for Roofs and Roof Elements

Belzona 3000 series fluid-grade membranes for weatherproofing, waterproofing, repair and protection of all roof types and roof parts.

Examples of Belzona Applications on Roofs:

FLOORS, STAIRS AND EXPANSION JOINTS

Damage to internal/external concrete floors, slippery transit and pedestrian areas, failure of expansion joints, – all these factors contribute to creating safety hazards.

Belzona Solutions for Internal and External Floors

Belzona 1000, 2000, 4000, and 5000 series paste- and fluid-grade materials for floor slip resistance, safety markings on floors and steps, concrete restoration and leveling, expansion joints repairs, replacement and installment of new expansion joints, steps and nosings restoration and protection, new floor installation in kitchens, dining halls, passenger waiting rooms, restrooms, entryways, parking lots, mechanical rooms, loading docks, waste and water management facilities.

Examples of Belzona applications on Floors:

HVAC SYSTEMS

Erosion-corrosion and chemical attack damage to components of HVAC units.

Belzona Solutions for HVAC Systems

Belzona 1000, 2000, 3000, 4000 and 5000 series paste-grade and fluid-grade materials for the metal rebuilding, concrete restoration and erosion-corrosion protection of boilers, air handlers, diesel engines, fans, pumps, condensers, generators, compressors, basins of cooling towers and basins

Examples of Belzona applications on HVAC units:

PIPES AND PIPEWORK

Erosion-corrosion damage to pipes and pipework, and water boilers and storage tanks.

Belzona Solutions for Pipes and Pipework

Belzona 1000 series 100% solids paste- and fluid-grade materials for metal rebuild and corrosion protection of the pipes, pipework and storage tanks. Belzona 5000 series fluid grade materials for the chemical resistance in chemical containment areas and corrosion protection of (non) potable water storage tanks and pipes.

Examples of Belzona applications on Pipework

ELEVATOR SYSTEMS

Corrosion, physical impact and wear from passenger and luggage transport, heavy foot traffic and movement.

Belzona Solutions for Elevator Systems

Belzona 1000, 2000, 4000, and 5000 series paste and fluid grade for metal rebuilding, leak sealing, concrete damage restoration, corrosion, floor and elevator pit protection.

Examples of Belzona applications in Elevators:

CURBSIDE APPEAL

A curbside appeal of any business creates the customers’ first impression. Airports are no different. Decorative structures located outdoors often suffer from concrete and metal damage due to erosion-corrosion, weathering, freeze-thaw cycle and physical impact. To maintain the curbside appeal pleasant-looking, inviting and safe, the decorative structures, floors and areas need to be repaired and/or provided with preventative maintenance.

Belzona Solutions for Decorative Structures

Main application areas that Belzona materials assist with are metal rebuilding, concrete restoration and protection on decorative structures and bases (fountains, waterfalls and monuments), concrete leveling, floor protection and slip-resistance on pedestrian walkways and at the base and around stop bollards and other safety structures, and UV-resistant corrosion protection of external metal and concrete surfaces.

Solutions: Belzona 1000, 4000, 5000, and 6000 series paste-grade and fluid-grade materials.

Examples of Belzona applications on Decorative Structures:

POWER GENERATION (IF APPLICABLE)

Typically, corrosion related to elevated pressure and temperature causes damage to boilers, steam turbines, heat exchangers, and pipework.

Belzona Solutions for Power Generation Units and Equipment

Belzona 1000 and 5000 series paste-grade and fluid-grade materials may be used for metal rebuild and erosion-corrosion protection on solar panels, transformers, generators. Belzona 6111 fluid-grade material for the cathodic protection on solar panels supports and other metallic structures.

Examples of Belzona applications in power generation:

WASTEWATER MANAGEMENT (IF APPLICABLE)

Erosion-corrosion on sedimentation and flotation clarifiers, aeration tanks, holding tanks, pipework, pumps, and centrifuges. For more information on problems that the wastewater industry may experience and solutions that Belzona may offer, read our post “Polymeric Solutions for Water and Wastewater Industries”.

Belzona Solutions for Wastewater Management

Belzona 1000, 2000, and 5000 series paste-grade and fluid-grade materials may be used for the metal rebuilding and erosion-corrosion protection. Belzona 4000 series paste-grade and fluid-grade materials can assist with the concrete rebuilding and protection of concrete under immersion, thus adding corrosion and chemical attack resistance to clarifiers and other tanks. Belzona 3111 fluid-grade flexible membrane may be used for the sealing of tank bases suffering from water ingress.

Examples of Belzona applications in Wastewater plants:

VIDEO: BELZONA SOLUTIONS FOR FACILITIES MAINTENANCE

Contact your local Belzona representative to discuss the needs of your airport facilities

Yulia Burova, Marketing Director, Belzona Inc., Miami FL, USA