“Quality means doing it right when no one is looking”; a principle upheld by manufacturing pioneer, Henry Ford. He recognised that for any successful organisation, its attitude to quality must not be one-dimensional but habitual; particularly from a manufacturer’s perspective. Following the first in the ‘Differentiating Belzona’ series, this post expands upon the theme of quality in the transition from the initial science, through to the delivery of the final Belzona solution. From raw material selection, we trace the journey of every solution, examining the testing procedures undertaken and the production process itself. Interviewing those in the know, we discuss the specific markers which Belzona has established to improve quality and serve as a further differentiator.

Selecting the materials

In the previous post, the importance of chemical composition was explored, as well as Belzona’s proactive stance towards managing hazardous chemicals. Significantly, Belzona adopts a similarly proactive approach to its selection of raw materials.

Terri Gladman, Quality Control Technician for Belzona, highlighted, “Ensuring that there is consistency in the sourcing of raw materials is vital. As a result, Belzona checks that all of the selected raw materials meet specific criteria based upon performance, quality and safety. Achieving this consistency improves the reliability of all products manufactured, providing both Belzona and its customers with increased confidence in product performance.”

“Belzona achieves standardisation of raw materials by setting specifications during product development. These are key to the levels of quality we expect, as each raw material has a specific set of parameters which are tested to ascertain it is fit for purpose. Testing these parameters varies depending on the type of material, including analysis of moisture content, pH, density, particle size and distribution, viscosity, and refractive index. In addition, the behaviour of some critical materials is tested by evaluating them in finished product formulations, looking at the rate of exothermic reactions, the tensile properties of elastomer compounds, corrosion resistance or simply the colour or hardness of the final product.”

The supply of Belzona’s raw materials can, on occasion, be threatened due to supplier’s withdrawal or feedstock shortages. Therefore, what happens when raw materials are at risk? Terri Gladman explained “Belzona routinely looks at new raw materials used in pour products’ formulation, researching the capabilities of those materials in direct comparison with our current specification. Our experienced team is dedicated to looking at alternative suppliers and keeping an eye on improved raw materials. This allows us to maintain supply and quality should we experience difficulties with any supplier”.

Put it to the test

Upon the realisation and formulation of a new solution, proving that it works is an essential part of the R&D phase. At this stage, a wide variety of performance tests will be carried on the product to demonstrate that it can withstand the service conditions associated with the end user application. This information is then made available to customers in the form of Belzona product literature, so that customers can make an educated choice as to the suitability of that solution in protecting their asset. Of course, Belzona’s competitors will follow similar development and testing process, but it is important to recognise that not all suppliers will offer test data created with the same level of expertise, diligence and reliability.

Jevon Pugh, Belzona’s R&D Director, commented “One way in which Belzona differentiates itself from competitors is in the quality and quantity of lab data generated. Wherever possible, we will test to recognised international standards, such as ISO, ASME and NACE, so that our results are reliable and can be interpreted, as well as understood, by customers. We will also push our products to failure, so that we understand their limitations, whilst running tests for extended periods to provide the best possible results.”

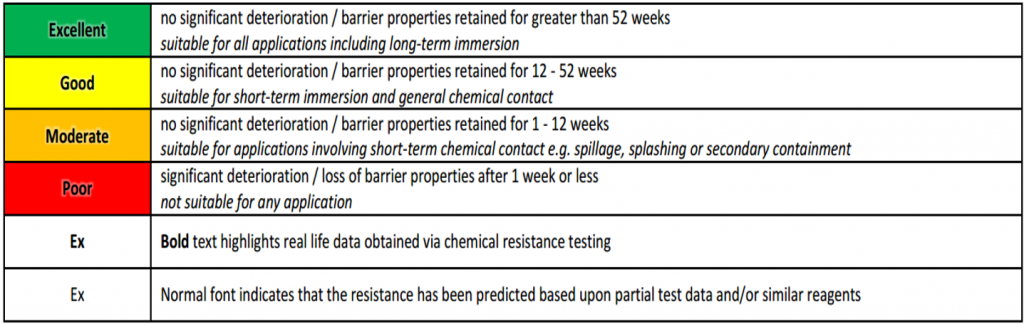

Belzona’s 12-month chemical resistance test is proof of this philosophy. For any industrial coating, the ability to resist commonly encountered chemicals is important; therefore, Belzona coatings are assessed via immersion testing in accordance with ISO 2812-1. Mild steel rods are coated in line with Belzona’s application guidelines before being immersed in various chemicals at ambient and elevated temperatures (depending on the application). The observations from this testing, coupled with the length of exposure, are then used to assign a chemical resistance rating. Belzona coatings typically need to survive a 52-week test regime before they will be rated Excellent against that chemical. Contrast this to competitor coatings and their data, in which it is common coatings to be rated Excellent (or equivalent) after tests periods as short as 28 days.

Furthermore, as Belzona is a global organisation, it is important to establish that products can perform in a variety of climates, whether those are the freezing temperatures in Scandinavia, dry and scorching heats of the Middle East, or humid surroundings of South East Asia. Testing is therefore carried out to assess properties over a range of climates, facilitated by Belzona’s investment in a Climate Control Chamber. This equipment allows product features such as working life and cure time, to be measured at a range of temperatures and humidity, thereby ensuring that materials are suitable for use in all Belzona’s markets.

However, R&D Director, Jevon Pugh added “We recognise that not every test can be completed in-house. For example, some tests are too dangerous for our lab environment or require very specialist equipment. In these scenarios, we will invest in external testing carried out by independent, third-party test houses at external test houses/companies. Importantly, independent test results also serve to enhance and verify our own claims, which may be necessary for some clients or products, a good example being Belzona SuperWrap II. Due to its use in safety critical environments, SuperWrap II required external testing to extreme pressure levels in order to comply with designated ISO and ASME standards”.

Producing the solution

Without an efficient production process, the quality assurance provided during raw material selection and testing would be irrelevant. Therefore, effective control of this process is crucial to ensuring that customers receive the highest quality products. At Belzona, this is encompassed by the Production Order. This document travels along every step of the production process, specifying everything from the appropriate container, the raw materials in the batch, the equipment used to make the batch and the QC specification for the finished product.

Helen Parris, Belzona’s SHEQ Manager, indicated “Traceability is fundamental to the entire process and is something Belzona actively pursues throughout all our manufacturing systems. Our systems and documentation guarantee a high level of traceability and reproducibility for every batch. In addition, there is also a team of Process Chemists who act as guardians of quality on the factory floor, ensuring that control protocols are followed correctly.”

As a vital part of quality assurance protocols, Belzona keeps a set of samples of every batch it manufactures for up to five years. Helen Parris stated “As a safeguard for Belzona and our customers, storage sample are retained and regularly inspected throughout their storage life. This allows us to check product batches many years after they have been manufactured, one of the reasons why Belzona products have such long shelf-lives versus our competitors”.

“Belzona takes pride in its rigorous production process and frequently hosts external auditors who independently verify its quality, with recent examples being the American Bureau of Shipping, NSF International and Bureau Veritas.”

Conclusion

As highlighted at the very beginning of the post, quality is a trait that need to be rooted in all processes and procedures. With regards to Belzona, Helen Parris, SHEQ Manager, summarised “I would suggest that Quality management is inbuilt throughout Belzona’s organisation. This not only ensures that we conform to our quality processes, but it also ensures that continual improvements are made to further enhance the value of Belzona’s solutions and services, as well as customer satisfaction. Overall, the dedication to sourcing consistent raw materials, the combination of in-depth testing and manufacturing checkpoints, aids the transition from science through to solution.”

The next and final post in the series, will take a closer look at what differentiates Belzona once the solution has been made available, encompassing the global provision of support out in the field.