Belzona 1341 (Supermetalglide): A Proven Pump Coating that Saves up to 20% in Energy Costs

As global energy prices continue to rise, manufacturing and industrial operations are under pressure to reduce costs and improve energy efficiency. These are key assets that can suffer from corrosion, cavitation, and performance degradation over time.

When pump performance declines, the result is increased power consumption and higher lifetime operational costs. This makes improving pump efficiency with a pump coating a critical focus for industries seeking both cost reductions and environmental impact improvements.

Why Use a Pump Coating?

One effective and proven way to restore and improve pump performance is by applying pump efficiency coatings that are specifically designed to resist erosion and corrosion. Hydrophobic coatings, which repel water and reduce surface friction, are a smart solution for enhancing efficiency in new and existing pumps.

Belzona has been delivering innovative industrial pump coatings solutions for over 70 years. Among these, Belzona 1341 (Supermetalglide) stands out for its advanced hydrophobic properties and long-term erosion and corrosion protection.

This energy-saving coating has been engineered to reduce internal friction losses, thereby lowering the energy input required to operate the equipment. In fact, Belzona 1341 (Supermetalglide) can boost hydraulic efficiency by:

- 3–8% in new pumps

- Up to 20% in pumps already in service

This leads to reduced electrical consumption and significant energy savings, a major advantage for facilities running multiple pumps around the clock.

Step-by-Step Guide: Applying a Pump Efficiency Coating with Belzona 1341 (Supermetalglide)

This guide demonstrates how Belzona 1341 (Supermetalglide), a leading pump efficiency coating, can restore damaged pump components while delivering long-term energy savings and performance improvements for industrial pump systems.

Step One: Surface Decontamination

Start by degreasing the surface with Belzona 9111 or MEK to remove any contamination. Next, abrasive blast the equipment to a standard of SSPC SP-10 to remove any previous coatings or loose substrate to create a profile for the industrial coating to adhere to. Finally, use a salt removal solution to eliminate all residual contaminants, which could otherwise compromise coating adhesion.

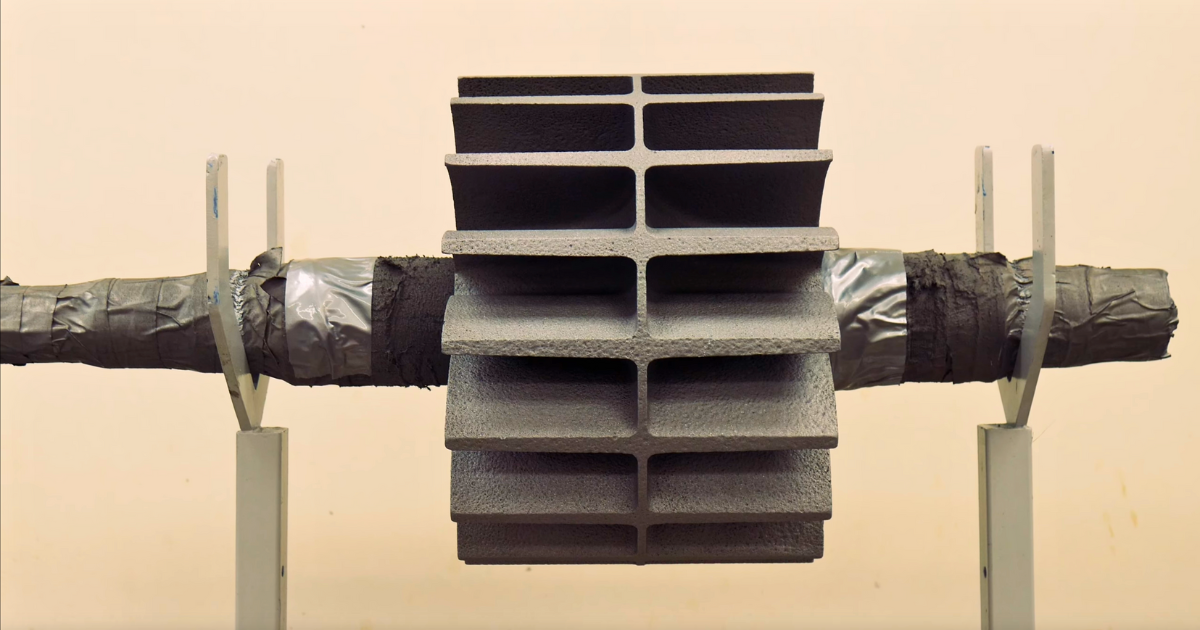

Step Two: Mask the Application Area

Apply masking tape to clearly define the area where Belzona 1341 (Supermetalglide) will be used. This ensures a clean and controlled coating boundary.

Step Three: Abrasive Blast the Surface

Use angular grit abrasive blasting to achieve a near white metal finish with a surface profile of at least 3 mils (75 µm). Proper surface preparation is essential for maximum adhesion and long-term corrosion protection.

Step Four: Mix the Coating Components

Following Belzona’s Instructions for Use, measure one part of the Belzona 1341 (Supermetalglide) Base and one part of the Solidifier using a clean measuring cup. Mix the two components thoroughly until a uniform color is achieved.

Step Five: Apply the First Coat

Using a stiff-bristled brush, apply an even coat of the pump coating. Ensure the material is worked well into the prepared surface. Use a wet film thickness gauge to check that the application meets the specified coating thickness.

Step Six: Allow to Cure

Let the first coat cure. As soon as possible after the first application of the first coat, apply a further coat of Belzona 1341 (Supermetalglide).

The first coat must not be left longer than 24 hours before overcoating, irrespective of temperature.

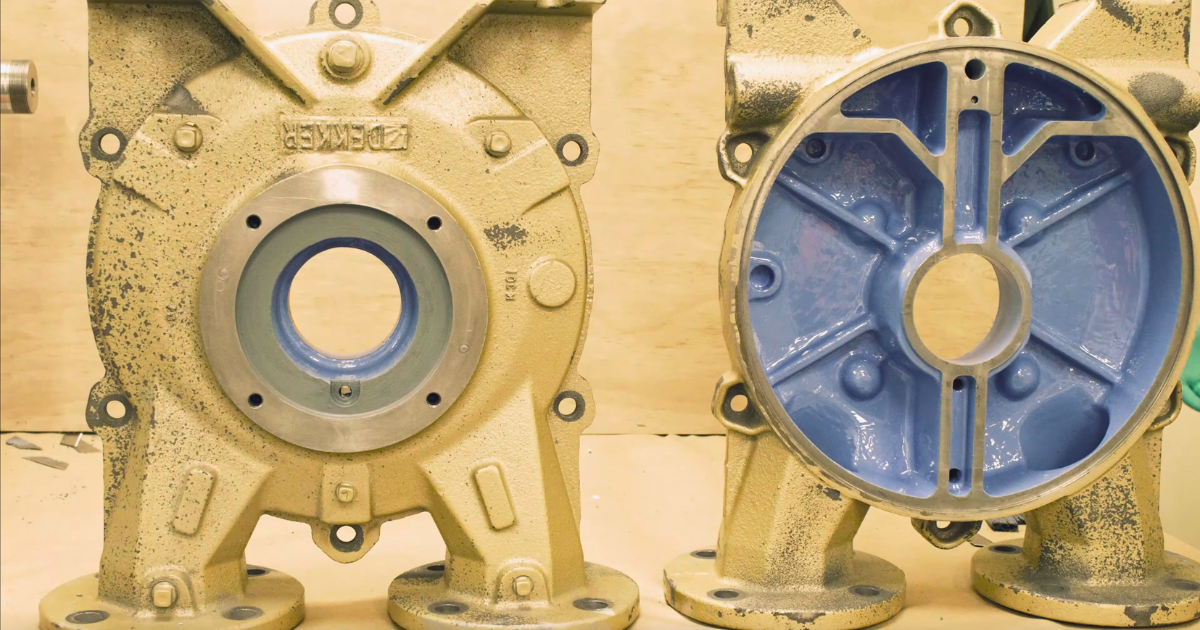

Step Seven: Apply the Second Coat

Mix a second batch of Belzona 1341 (Supermetalglide) using a different color for visual contrast. Apply a uniform second coat, ensuring complete coverage of the base layer.

Allow for the second coat to cure as per the pump coating’s Instructions for Use. Once fully cured, the hydrophobic coating is complete, providing high-performance corrosion protection and enhanced pump efficiency.

Invest in Pump Efficiency, Save in the Long Run

Whether dealing with aging assets or installing new systems, applying a hydrophobic, pump coating like Belzona 1341 (Supermetalglide) can significantly increase pump efficiency and reduce energy consumption.

From restoring worn pumps to outperforming OEM parts, industrial pump coatings are a smart investment for improving performance, cutting energy costs, and supporting sustainability goals.

This video demonstrates the procedure of applying Belzona 1341 (Supermetalglide):

Frequently Asked Questions

How can I increase the efficiency of my centrifugal pump?

To increase the efficiency of a centrifugal pump, such as a Goulds 3196 or KSB Etanorm, among others, you can apply a pump efficiency coating like Belzona 1341 (Supermetalglide). This hydrophobic coating reduces internal fluid friction, leading to improved hydraulic efficiency and lower energy consumption. Gains of up to 20% in efficiency have been recorded on refurbished pumps.

What is a hydrophobic coating, and how does it help pumps?

A hydrophobic coating is a material that repels water, minimizing surface drag and resistance. In industrial pumps, such as the Sulzer AHLSTAR A or Grundfos CR series, this results in smoother fluid flow and reduced turbulence, which improves overall pump performance and energy efficiency.

Can pump coatings reduce energy costs?

Yes. Applying an energy-saving coating like Belzona 1341 (Supermetalglide) can significantly reduce energy input by improving flow efficiency and decreasing resistance inside the pump. Case studies show annual energy cost savings of over £14,000 for a single refurbished end-suction pump.

What types of pumps benefit most from industrial pump coatings?

Industrial pump coatings are effective on a wide range of equipment, including:

- Split-case pumps (e.g., Flowserve HSC)

- Vertical turbine pumps (e.g., Pentair Fairbanks Nijhuis VTP)

- End-suction centrifugal pumps (e.g., Wilo CronoBloc-BL)

These coatings enhance pump performance, especially in high-wear applications or environments prone to erosion and corrosion.

Learn More

Marine Coatings and Composites: Six Key Maintenance Areas

Mining & Quarrying: Belzona’s Top 5 Application Areas

Top Repair Materials and Coatings for the Sugar Industry

Pulp and Paper: 4 Key Maintenance Areas

Contact Your Local Distributor to Learn More About Belzona Solutions for Pumps

Phil Robinson is an Association for Materials Protection and Performance (AMPP) Coating Inspector Program (CIP) Level 3 Inspector, with nearly 20 years of experience in executing major Belzona applications worldwide, both onshore and offshore. He currently holds the position of Applications and Training Director, based at Belzona’s Headquarters in Harrogate, UK. His expertise spans multiple industries, with a primary focus on the preservation of process equipment in the oil and gas sector.

In addition to his field experience, Phil plays a key role in the development of Belzona training programs, supporting Belzona’s global Distributor Network. He has also developed numerous application procedures and techniques to enhance the effectiveness of the product range. For example, in 2024, Phil was one of the key developers behind Belzona SF6-FIX, a sulphur hexafluoride (SF₆) leak solution that can be applied online, and without specialist tools.

With a passion for troubleshooting and implementing technical solutions, Phil excels at identifying and resolving complex challenges utilising protective coatings and repair composites.