- 1. Corrosion Damage in Process Vessels

- 2. Chemical Attack in High Temperature Scrubbers

- 3. Erosion-Corrosion in Heat Exchangers

- 4. Flange Faces and Nozzle Connections Exposed to High Temperatures

- 5. Corrosion of Pipework at Elevated Temperatures

- Find the Right High Temperature Epoxy Solution

- Frequently Asked Questions

- Learn More

High temperature epoxy solutions are often specified where internal corrosion, erosion, chemical attack, and thermal cycling have deteriorated equipment operating at elevated temperatures.

When repairing high-temperature assets, including distillation columns, knockout drums, separators, heat exchangers, piping, and pumps, traditional methods such as glass flake and rubber linings, metallic alloys, welding or component replacement are widely used, but can present limitations in situations where fast, in-situ repairs are required.

Epoxy-based solutions offer a practical, engineered alternative. High temperature epoxy systems are widely used to rebuild damaged metal, restore performance, and extend service life without prolonged downtime. They are designed to provide long-term protection at elevated temperatures while resisting chemical and mechanical attack.

This blog highlights five common industrial problems that high temperature epoxy solutions can address effectively.

1. Corrosion Damage in Process Vessels

The Problem: Process vessels operating at elevated temperatures and pressures represent one of the most arduous service environments and major challenges for asset owners and operators. These vessels, and particularly those involved in the separation of oil/water and gas as it enters the process stream, are subjected to a wide variety of aggressive conditions which can ultimately lead to severe internal erosion and corrosion.

The Solution: High temperature epoxy solutions can be used to rebuild corroded steel surfaces at elevated pressures and temperatures and provide a chemically resistant barrier.

- Belzona 1511 (Super HT-Metal) has been specifically designed for use with high temperature epoxy coatings and will restore metal loss caused by erosion-corrosion. Once cured, the material is durable yet fully machinable. It can also be used as a high strength structural adhesive for bonding.

- Belzona 1593 is a hand applied high temperature lining, suitable for continuous immersion in aqueous / hydrocarbon systems up to up to 320°F (160°C) which provide long-term corrosion protection at elevated temperatures and protects against a wide range of chemicals.

2. Chemical Attack in High Temperature Scrubbers

Internal of a Scrubber rebuilt with Belzona High Temperature Epoxies

The Problem: Scrubbers operate in aggressive environments combining heat, moisture, and corrosive chemicals. Rubber linings and metallic alloys can degrade rapidly, especially during temperature fluctuations.

The Solution: A high temperature epoxy lining provides seamless chemical resistance and tolerance to operating and cleaning temperatures.

- Continuous immersion at elevated temperatures

- Steaming-out up to 427°F (220°C)

- Resistance to a wide range of industrial chemicals

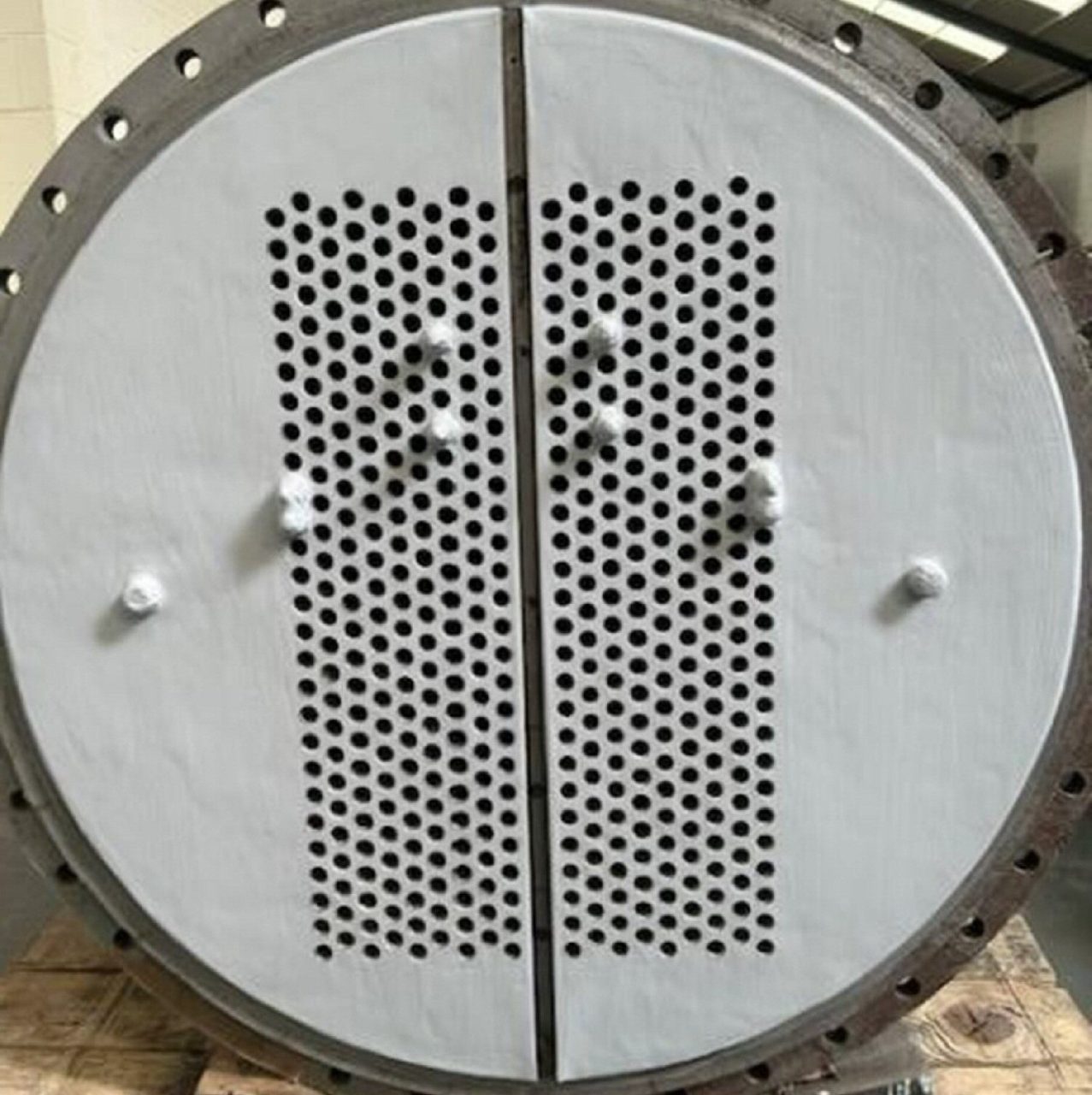

3. Erosion-Corrosion in Heat Exchangers

The Problem: Heat exchangers are exposed to erosion-corrosion from high flow velocities and turbulence, often compounded by electrolytic (galvanic) corrosion between dissimilar metals. This can lead to wastage and cracking of tube sheet ligaments, resulting in leakage of system fluids across the tube sheet and a loss of exchanger integrity. Chemical attack from process or cooling media further accelerates degradation at elevated temperatures.

The Solution: High temperature epoxy solutions are ideal for rebuilding eroded metal profiles using Belzona 1511 (Super HT-Metal). A protective coating was then applied to reduce turbulence and corrosion. This approach helps maintain thermal efficiency while avoiding costly exchanger replacement.

4. Flange Faces and Nozzle Connections Exposed to High Temperatures

The Problem: Flange face corrosion is a common issue on pressure vessels operating at elevated temperatures, where exposed sealing surfaces must be effectively isolated to prevent oxidation and loss of sealing integrity. Small-bore nozzles are particularly vulnerable to erosion-corrosion in high-temperature service, often deteriorating rapidly due to high velocities, turbulence, and abrasive process media. Their length and narrow geometry make them difficult to protect using conventional coating systems, which are prone to pinholes and holidays, leaving the substrate exposed.

The Solution: High temperature epoxy composite systems provide a reliable method of rebuilding and isolating vessel weak points exposed to elevated operating temperatures. Flange faces can be restored using prefabricated formers to accurately shape Belzona materials that bond strongly to the substrate and do not corrode. For small-bore nozzles, inserts manufactured from high temperature epoxy composites are installed and bonded in place, eliminating the risk of pinholes while providing continuous corrosion protection. When installed with compatible coating-grade materials, these inserts form a sealed, erosion-resistant barrier and can also act as a sacrificial layer in highly abrasive conditions.

Pre-formed nozzle inserts made and bonded with high temperature epoxies

5. Corrosion of Pipework at Elevated Temperatures

Belzona SuperWrap II applied on a 58″ flare line at a Petrochemical Plant in Saudi Arabia

The Problem: Pipework operating at elevated temperatures is vulnerable to corrosion driven by aggressive process media, moisture ingress, and thermal cycling. Conventional repair methods such as welding or pipe replacement often require hot work and extended shutdowns, increasing safety risks, downtime, and costly repairs.

The Solution: Belzona SuperWrap II (1983 Resin) provides a cold-applied composite wrap system for reinforcing and protecting pipework operating at elevated temperatures up to 302°F (150°C). The system can be designed and applied in accordance with ISO 24817 and ASME PCC-2, ensuring structural integrity and long-term performance. Belzona SuperWrap II offers a reliable alternative to welding, mitigates the need to replace defective metallic substrates, and provides superior strength, chemical and corrosion resistance. Thus extending the service life of high-temperature pipework.

Find the Right High Temperature Epoxy Solution

If you’re facing corrosion, erosion, or chemical attack at elevated temperatures, Belzona’s high temperature epoxy systems provide proven, in-situ solutions for restoring and protecting critical industrial equipment

Frequently Asked Questions

What should be considered when selecting a high temperature epoxy for process equipment?

Selecting the right high temp epoxy starts with understanding the actual service conditions, not just the operating temperature. Key factors include:

- Continuous and peak operating temperatures

- Chemical exposure (aqueous, hydrocarbons, acids, cleaning chemicals)

- Immersion vs. splash or intermittent service

- Thermal cycling and shutdown conditions

- Substrate condition and surface preparation feasibility

A fit-for-service high temperature epoxy system should be chosen based on long-term resistance, not short-term temperature limits alone.

Why is surface preparation critical when installing high temp epoxy linings?

Surface preparation is one of the most common causes of lining failure. Even the best high temp epoxy will underperform if applied to a poorly prepared surface.

Best practice includes:

- Abrasive blasting to the correct cleanliness and profile

- Removal of salts, moisture, and contaminants

- Ensuring the substrate is sound and free from active corrosion

Proper surface preparation ensures mechanical adhesion, which is essential for epoxy performance at elevated temperatures.

Learn More

Contact Your Local Distributor to Learn More About High Temperature Epoxies

Isaac Atkinson joined Belzona in 2016 as a Technical Service Engineer, based at the Company’s headquarters in Harrogate, UK. In this role, he supported field sales engineers, consultants, and clients across Europe and Africa. He conducted product demonstrations, site surveys, technical presentations, and tender reviews, while liaising with Distributors, regulatory bodies, and industry organisations.

In his current role as Product Manager, Isaac oversees technical communication, product portfolio management, and helps to facilitate new product development. His responsibilities span creating technical literature, securing external product approvals, coordinating product launches, and facilitating cross-departmental collaboration to ensure seamless innovation.

A graduate of Northumbria University with a Master’s in Mechanical Engineering, Isaac is also ICorr Level 2 certified in Protective Coatings Inspection and a member of AMPP. With a wealth of expertise in corrosion, coatings, and inspection services, he continues to contribute to advancing high-performance solutions in the coatings industry.